VALIDATION OF WATER SUPPLY SYSTEM

advertisement

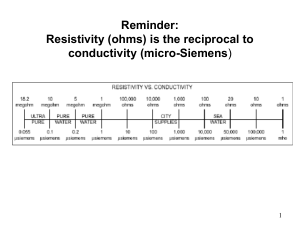

VALIDATION OF WATER SUPPLY SYSTEM MALIBA PHARMACY COLLEGE. 1 CONTENTS Objectives Introduction Validation & System Qualification Monitoring Maintenance Revalidation & Change control Validation documentation Summary 2 OBJECTIVE To understand: 1. 2. 3. 4. 5. 6. 3 The need for water quality manual reason for usage of pharmaceutical water supply systems. The technical requirements for water supply systems. Different types of water supply systems. Validation requirements. Qualification & inspection requirement INTRODUCTION High-quality water is essential for the manufacturing of pharmaceuticals. Water is the most commonly used raw material in pharmaceutical manufacturing. water is directly or indirectly used in the pharmaceutical manufacturing such as a major component in injectable products and in cleaning of manufacturing equipment. It is one of the raw material that is usually processed by the pharmaceutical manufacturer prior to use because it cannot be supplied by the vendor. Water is thus an important raw material in GMP and in validating the manufacturing process. 4 INTRODUCTION Why purification? o Although tap water is reasonably pure, it is always variable due to seasonal variations, regional variation in quality. o One must remove impurities and control microbes to avoid contamination of products. o Pretreatment depends on quality of feed water. 5 INTRODUCTION Quality of water should be specific for product quality. Water contains, Organic and inorganic impurities Microbial contamination Endotoxin Particulate contamination 6 Low quality of water can lead to product degradation product contamination loss of product and profit TYPES OF WATER Different grades of Water for Pharmaceutical Purposeseach type has its on characteristic for all parameters. Potable water Purified water Water for injection(WFI) Sterile water for injection, inhalation, irrigation Sterile bacteriostatic water for injection 7 8 9 DIFFERENT TECHNIQUES USED FOR WATER TREATMENT De-chlorination (Sodium Bisulphite, 10 Carbon Filter) Filtration Ultra Filtration Softening Demineralization Reverse Osmosis UV Treatment Deionization Ozonization DIFFERENT EQUIPMENTS AND COMPONENTS FOR WATER SYSTEM Piping Valves Pumps Pressure gauges Heat exchangers Distillation unit Filters Deionizers Sensors 11 Auxiliary equipment WATER STORAGE AND DISTRIBUTION – CONSIDERATIONS Materials of Construction (Chemical and Compatibility) Stainless Steel (316 or 316L) Teflon, Silicone, Viton (gaskets, diaphragms) Heat Minimize Dead Legs (<= 2 pipe diameters) Smooth Surfaces (Mechanical Polish , Electropolish) Clean joints (sanitary Tri®Clamp, automatic orbital 12 welding) Passivate interior surfaces to form barrier between water and free iron (0.5 to 1% alkali at 160ºF for 30 minutes followed by 1% Phosphoric Acid or Nitric Acid at 150ºF to 180º F for 10 minutes.) Conti…. Design of the following should be appropriate to prevent recontamination after treatmentVent filter Sanitary overflow Tank UV light Conical Bottom Steam sterilization Combination of on-line (TOC, Conductivity meter etc.) and off-line monitoring (lab testing by proper sampling) to ensure compliance with water specification 13 VALIDATION CONCEPT To prove the performance of processes or systems under all conditions expected to be encountered during future operations. To prove the performance, one must demonstrate (document) that the processes or systems consistently produce the specified quantity and quality of water when operated and maintained according to specific written operating and maintenance procedures. validation involves proving- 14 1. Engineering design 2.Operating procedures and acceptable ranges for control parameters 3. Maintenance procedures to accomplish it Conti.. the system must be carefully, -designed -installed -tested during processing, after construction, and under all operating conditions. Variations in daily, weekly and annual system usage patterns must be validated. 15 WHY VALIDATION OF WATER SYSTEM? Most widely used and sometimes most expensive 16 ingredient Drug component even if not in product Generally reviewed in depth by Regulators Many recalls water related Always considered direct impact system To ensure reliable, consistent production of water of required quality To operate system within design capacity To prevent unacceptable microbial, chemical and physical contamination during production, storage and distribution To monitor system performance, storage and distribution systems VALIDATION CYCLE: It includes four major steps Determination of Quality Attributes The Validation Protocol Steps of Validation Control during routine operation 17 DETERMINATION OF QUALITY ATTRIBUTES The quality attributes, is gaining a clear understanding of the required quality of water and its intended use Should be validation. determined before starting the Without defining required quality attributes, we cannot establish validation protocols. 18 THE VALIDATION PROTOCOL A written plan stating how validation will be conducted and defining acceptance criteria for quality. For example, the protocol for a manufacturing process- 19 it identifies -process equipment -critical process parameters -product characteristics, -sampling, -test data to be collected, -number of validation runs -acceptable test results STEPS OF VALIDATION Establishing standards for quality attributes Defining system and subsystem Designing equipment, control, & monitoring technologies Establishing standards for operating parameters Developing an IQ stage & OQ stage Establishing alert and action levels Developing a prospective PQ stage Completing protocols and documenting each steps 20 Conti… 21 ALERT AND ACTION LEVELS: Alert and action levels are distinct from process 22 parameters and product specifications. They are used for monitoring and control rather than accept or reject decisions. The levels should be determined based on the statistical analysis of the data obtained by monitoring at the PQ step. Alert levels are levels or ranges that when exceeded indicate that a process may have drifted from its normal operation condition. Alert levels indicate a warning and do not necessarily require a corrective action. Exceeding an action level indicates that corrective action should be taken to bring the process back into its normal operating range. SYSTEM QUALIFICATION Validation Master Plan User Requirement Specification Design Qualification Installation Qualification Operation Qualification Performance Qualification Re- Qualification. 23 DESIGN QUALIFICATION OF WATER SYSTEM Based on the URS, supplier designs the equipment. This is 1st step in the qualification of new water supply systems. Define process schematically by use of PFD and P&IDs. It is documented the design of the system & will include : -Functional Specification.(Storage, purification, etc) -Technical/Performance specification for equipment.(requirements of water volume and flow, define pumps and pipe sizes ) -Detailed layout of the system. Design must be in compliance with GMPs and other regulatory requirements. 24 INSTALLATION QUALIFICATION IQ is in the form of checklist and it should include- 25 Instrumentation checked against current engineering drawings and specifications Review of P&ID Verification of materials of construction Installation of equipment with piping Calibration of measuring instruments Collection and collation of supplier operating and working instructions and maintenance requirements Conti… Installation of system as per Design requirements. Installation Verification- Systematic range of adjustments, measurements and tests should be carried out to ensure proper installation. Documentation installation. 26 include details of completed Conti… • IQ Document should contain, Instrument name, model, I.D. No., Personnel responsible for activities and Date. A fully verified installation that complies with the documented design. (all deviations will have been recorded and assessed.) All equipment documentation and maintenance requirements would be documented. Completed calibration of measuring instruments. Verification of Materials of construction. 27 OPERATION QUALIFICATION Definition : The purpose of OQ is to establish, through documented testing, that all critical components are capable of operating within established limits and tolerances. it is the functional testing of system components mainly the critical components. The purpose of OQ is also to verify and document that the water supply system provides acceptable operational control under “at-rest” conditions. 28 Conti… Operation Qualification Checks- 29 Ability to provide water of sufficient quality and quantity to ensure achievement of specifications. Ability to maintain general parameters like temperature, pressure, flow at set points. Ability to maintain any critical parameters(pH, TOC, endotoxin, microbial level, conductivity etc ). Conti… 30 Includes the tests that have been developed from knowledge of processes, systems and equipment. Tests include a condition or a set of conditions with upper and lower operating limits, sometimes referred to as ‘worst case’ conditions. PERFORMANCE QUALIFICATION 31 The purpose of PQ is to verify and document that water supply system provides acceptable control under ‘ Full Operational ‘ conditions. PQ should follow successful completion of IQ and OQ. PQ verifies that over time, the critical parameters, as defined in the DQ are being achieved. Conti… According to the FDA’s advice: “The observed variability of the equipment between and within runs can be used as a basis for determining the total number of trials selected for the subsequent PQ studies of the process.” 32 Conti… 33 PQ is used to demonstrate consistent achievement of critical parameters over time. (such as pH, TOC, conductivity) PQ and OQ tests are sometimes performed in conjunction with one another. QUALIFICATION PHASES Three phase approach recommended according to WHO Technical Report Series 929 to prove reliability and robustness. Phase 1 (investigational phase): A test period of 2-4 weeks – monitor the system System to operate continuously without failure or performance deviation Chemical and microbiological testing should include in accordance with a defined plan 34 Conti… Sample daily from incoming feed-water after each step in the purification process each point of use and at other defined sample points Develop: appropriate operating ranges and finalize operating, cleaning, sanitizing and maintenance procedures 35 Conti… Demonstrate production and delivery of water of the required quality and quantity Use and define the standard operating procedures (SOPs) for operation, maintenance, sanitization and troubleshooting Verify provisional alert and action levels Develop and define test-failure procedure 36 Phase 2(verification step) A further test period of 2-4 weeks – further intensive monitoring of the system Utilization of all the SOPs after the satisfactory completion of phase 1 Sampling scheme generally the same as in phase 1 Water can be used for manufacturing purposes during this phase 37 Conti.. Phase-2 demonstrates: Consistent operation within established ranges. so it demostrate that the system is in control. Consistent production and delivery of water of the required quantity and quality when the system is operated in accordance with the SOPs. 38 Phase 3 Over 1 year after the satisfactory completion of phase 2 Water can be used for manufacturing purposes during this phase Demonstrate: extended reliable performance that seasonal variations are evaluated Sample locations, sampling frequencies and tests should be reduced to the normal routine pattern based on established procedures proven during phases 1 and 2 39 MONITORING Monitoring and feed back data are important in maintaining the performance systems. Monitoring parameters include: Flow, pressure, temperature, conductivity, TOC Samples taken: From points of use, and specific sample points In a similar way how water is used in service Tests should include physical, chemical and microbial 40 attributes For example, stable state can be achieved by applying automatic continuous monitoring of TOC and conductivity of the water system. They are the major quality attributes of water by which organic and inorganic impurities can be determined. MAINTENANCE A controlled, documented maintenance covering : Defined frequency with plan and instructions Calibration programme SOPs for tasks Control of approved spares Record and maintenance 41 review of problems and faults during MAINTENANCE System sanitization and bioburden control Systems in place to control proliferation of microbes Techniques for sanitizing or sterilization Consideration already during design stage – then validated Special precautions if water not kept in the range of 70 to 80 degrees Celsius REVALIDATION & CHANGE CONTROL Once the validation is completed, the standard operating procedures (SOPs) are formalized. Routine operation should be performed according to the established SOP. If any deviation from SOP observed, determine the change and their impact on whole system Revalidation and evaluation should be performed depending upon the impact of the change on system. 43 VALIDATION REPORT Written at the conclusion of the equipment IQ, OQ and at completion of process validation. Will serve as primary documentation for FDA regulatory inspection Will serve as reference document when changes to the system are occurred and revalidation is needed. 44 VALIDATION REPORT STANDARD FORMAT 1. 2. 3. 4. 45 Executive summary Discussion Conclusions & recommendation List of attachment Topic should be presented in the order in which they appear in the protocol. Protocol deviation are fully explained & justified. The report is signed & dated by designated representatives of each unit involved in water system validation. Complete Documentation Verification of design documentation, including ◦ Description of installation and functions ◦ Specification of the requirements Instructions for performance control Operating procedures Maintenance instructions Maintenance records Training of personnel (program and records) Environmental records Inspection of plant Finally certification (Sign Off) by Engineering, User (Production) and QA Heads. 46 SUMMARY Water supply systems, Play a major role in the quality of pharmaceuticals. Must be designed properly by professionals. Must be validated as a critical system. 47 REFERENCES “Validation in pharmaceutical industry” ; edited by P.P. sharma ;first edition 2007 ; 193-220 Process Validation”; An international 3rd edition; edited by R. A. Nash and A. H. Wachter; 401-442 “Pharmaceutical “Validation of Pharmaceutical Processes”; by Agalloco James, Carleton J.Fredrick; 3rd edition; 59-92. "Pharmaceutical Process Validation", Drugs and Pharm Sci. Series, Vol. 129, 3rd Ed., edited by B. T. Loftus & R. A. Nash, Marcel Dekker Inc., N.Y. Pg. No. 440-460. 48 THANK YOU 49