Presentation

advertisement

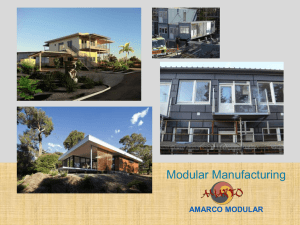

Modular Installation AMARCO MODULAR S Custom Modular Designer & Manufacturer. AMARCO means a ‘BEAUTIFUL PLACE’. When I decided on the name of the business I asked myself the question of “What I wanted to provide people when designing or manufacturing a modular building”. The answer came quickly and easily because I know what I want when I thought about a place to spend time in. Whether it be a mining danger or a house, I just wanted to be comfortable and safe, yes it must be a “Beautiful Place” to be in. We as inventors in a home or a project are always looking for faster, better and cheaper ways of living our lives. Within a short period of time we have landed on the moon in 1969 and the color TV was introduced only a short time later. From then on technology is travelling faster than we could ever imagine, IPhones, twitter and facebook are now the common words used throughout our lives. Custom Modular Designer & Manufacturer. THEN NOW When I looked at the building industry I recall working the two Italian bricklayers laying bricks with their trowels and I realized that the one industry in the world, which is one of the most important areas of our lives was moving very slowly in regards technological development. It was that thought and memory that inspired me to invest my time and money into finding a faster, smarter, safer and cheaper way to build a house. I have finally developed a system and a product that answers all the questions I posed to myself, which are now solutions for builders and owners. The answer is Modular Building. Custom Modular Designer & Manufacturer. We can now build a 4x2 single story house within 2 weeks rather than 6-8 months, that is incredible and if I hadn’t done it myself with my own hands I wouldn’t believe it. Not only do we enable a fast install time of a house we have increased the quality and strength incredibly. Additionally from an environmental factor we have decreased the environmental impact dramatically not only in the building of the house, by introducing fantastic insulation technology. You can now cool or heat a house at a margin of the cost because our houses are so well insulated. If you check to use our modular building products to build your next building project whether it be your own new home or a development or a hotel or a mining camp you can be guaranteed you will 100% save a great deal of time, money and stress without sacrificing quality . How we do it Amarco Modular are able to deliver a brilliant modular building because we have over 85+ years of combined experience in building, manufacturing, construction and management of modular buildings. More importantly all members of our team really love what they do . Our team comprises of tradespeople, technical people, artistic people who really do care about delivering a house, a unit, a hotel, a camp or a simple granny flat that will pass the test of time and is a true representation of them. Their signatures are on every building that is produced and we are all proud of that fact. Additionally to support our Australian ideology and integrity we have a partner factory who shares our values in all of what we produce together. They have 35 years of modular manufacturing experience producing amazing products. Together using our focus on quality control to Australian standards and our personal commitment to assuring only the best product is supplied to our customers. We are able to deliver a strong, reliable, high quality and artistically designed building every time. “THAT IS HOW WE DO IT” We invite you to take a look at our Installation Processes BEFORE AFTER SIX WEEKS OF BUILDING Installation Timeline Process To ensure a smooth and efficient installation process AMARCO has a set process and timeline for the installation of our Modular Buildings. This process can be altered and modified to suit all applications because the basic process is always the same. To manage and monitor these efficiencies we have fully experienced and trained installers and supervisors for Modular Installations. 1 Installation Process Installation of Footings There are 11 separate stations of production You will need to have your footings put down as per your engineering designs using either concrete footings, slab or the new technology, screw in pillions. Approximately 1 day of works. 2 Installation Process Installation of Bearers You need to lay your bearers on top of the footings in preparation for the modules to be craned onto. Approximately 1 day of works 3 Installation Process Transport of Units to Site You will need to have your modules transported to site using a flatbed truck. Once they arrive on site you will need to have a crane on site to lift your modules onto your footings or slab that you have already prepared 4 Installation Process Welding and Sealing Units Together Once units are located into position 5 Installation Process Install Roof Trusses and Roof Sheeting Approximately 3 days of works 6 Installation Process Electrical Installation Connection and commissioning of electrical system. With our newly innovated plug in system the installation process is dramatically decreased. Approximately 2 days of works 6 Installation Process Electrical Installation (Plug and Play Components) 7 Installation Process Plumbing Installation and connection of plumbing system. All plumbing services preplumbed before getting to site. Connecting waste droppers Digging trenches Connecting hot and cold water And then commission Approximately 2 days of works. 8 Installation Process Tiling Tiling of the units where the units join. Approximately 2 days of works Simply fill the rows of tiles left out when tiling works were completed during manufacturing factory in the factory. 9 Installation Process Gyprock Installation Installation of gyprocking where we leave only one sheet out where units join, which reduces time on site. Simply insert one sheet, flush and paint 1-1.5 days on site. 10 Installation Process External Cladding Installation of external cladding where units join. We leave small sections out when manufacturing so that only small areas where units join need to be filled. Again meaning only a day or 1.5 days sealing the external cladding. 11 Installation Process Decking, Steps and Veranda Installation Connection of decking and verandas to modules. Approximately 4 days of works. The Modular Home…..