Capital Goods Skills Council - DDU-GKY

advertisement

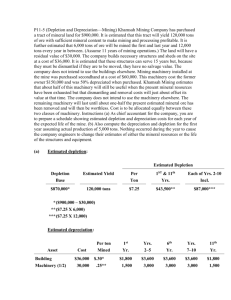

Capital Goods Skills Council A Brief 08 October 2013 Capital Goods Sector • Comprise of plant and machinery ,equipment / accessories required for manufacturing / production, either directly or indirectly, of goods or for rendering services, including those required for replacement, modernization, technological upgradation and expansion. • Also includes, packaging machinery and equipment, refrigeration equipment, power generating sets, equipment for testing, R&D, quality and pollution control. Capital Goods Sector has a multiplier effect and has bearing on the growth of the user industries as it provides critical inputs ie: Machinery and Equipment to the remaining sectors covered under manufacturing. Capital Goods Skill Council Supporting Organisations / Associations Promoter – FICCI Co-Promoter – DHI S.No Name of the Organisation 1 Larsen & Toubro 2 Thermax 3 BHEL 4 HEC Ltd 5 Bharat Forge 6 GW Precision Tools India 7 ALSTOM 8 Process Plant & Machinery Association of India (PPMAI) 9 Textile Machinery Manufacturers Association (TMMA) 10 Tool & Gauge Manufacturers Association (TAGMA India) 11 Plastic Machinery Manufacturers Association (PMMA) 12 Indian Machine Tool Manufacturers Association (IMTMA) 13 Engineering Export Promotion Council (EEPC India) Key Segments • Initial focus is on the following segments of Capital Goods Sector: – Machine Tools – Power and Electrical Machinery – Process Plant Equipment – Dies Moulds and Press Tools – Plastic Machinery – Textile Machinery – Light Engineering Industry Important Regions of Employment Concentration Sub-sector Key Geographic presence Machine Tools South and West Power & Electrical South, West and North Textile Machinery South, West and North Process Plant Machinery South and West Plastic, Paper and Rubber Machinery South and West Machine Tools Power & Electrical Process Plant Machinery Textile Machinery Plastic, paper & rubber Skill Requirements of the Industry • A Skill Gap Study has been done for the Sector by NSDC through KPMG with industry inputs. • Study highlights increased demand for: – Innovation and design roles. – Competent Managers. – Computer skills based jobs. – Multi-skilled employees. Brief Description of Major Roles (1/2) S.No. Core jobs in respect of all sub sectors of capital goods 1 Machinists include the operations such as turning, milling, drilling, grinding, tool sharpening, tool setting, gear hobbing, etc. 2 Machinist for large size machining application such as Boring/Slide way Grinding/Plano-milling 3 Machinist for precision machining for tool room applications, Precision Grinding, Jig boring, etc. 4 Welder for joining or welding operation 5 6 Electrician to assemble, install, test, and maintain electrical or electronic wiring, equipment, appliances, apparatus, and fixtures, using hand tools and power tools. Instrument Technician performs specific job duties such as inspecting and adjusting mechanical and pneumatic instruments and systems. also maintain metering and recording instruments in order to regulate the flow and water pressure of various types of manufacturing equipment. 7 Cable Operator for Wire drawing, Stranding operator, Extruder operator, Laying-up, Armour jointer, etc. 8 Operator for robotic material handling 9 CNC Programmer 10 Crane Operator for handling the raw materials and goods Brief Description of Major Roles (2/2) S.No. Core jobs in respect of all sub sectors of capital Goods 11 Tool and Die Maker Machine Builder/Assembler for performing the following jobs: 12 Fitting / Filing /Scraping, Hydraulic Assembly, Electrical Assembly, Pneumatic Assembly, Lead screw / Ball screw, fixturing & tooling assembly and whole machine assembly 13 Inspector for Adjustment test / Alignment test /Measurement & inspection 14 Designer for tool, fixture and machine tool, plastic machinery, earthmoving machinery, process plant machinery, textile machinery and its assemblies 15 Heat Treatment Operator and Forman 16 Expert in operating furnace and handling/fixing molten metal, ladles, etc. pattern making, sand mixing & casting, fettling, etc. 17 Specialist for Erection and Commissioning 18 Operator for surface coating, painting, etc. 19 20 Maintenance staff for Tooling maintenance, Preventive maintenance Service /Maintenance at customers’ end Middle level Managers with managerial skill for Shop Management, Marketing Management, vendor development, inventory management, Materials Management, Finance Management, Human Resources Management, IT Management like ERP etc. CGSC & STAR Scheme CGSC is participating in the recently launched STAR Scheme S. No • As on date, Four Qualification Packs comprising of 19 Occupational Standards are Ready. • Development of 50 more Qualification Packs with about 250 Occupational Standards is under way and is expected to be completed in phases by January, 2014. Existing Qualification Pack & REFERENCE ID 1 Welder CSC/ Q 0101 2 Fitter CSC/ Q 0102 3 Machinist CSC/ Q 0103 4 Tool and Die Maker CSC/ Q 0104 STAR Scheme Training Centre Alignment as on 08 Oct 2013 (work in progress) S. No 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 State Andhra Pradesh Chhattisgarh Gujarat Jammu and Kashmir Jharkhand Karnataka Maharashtra Meghalaya Madhya Pradesh New Delhi Odisha Punjab Rajasthan Tamil Nadu Tripura Uttar Pradesh Uttarakhand West Bengal TOTAL as on 08 Oct 2013 Total No. of Centres 3 1 19 1 1 1 1 1 9 1 3 2 4 2 1 2 1 3 56 Thank You