Importance of CM/DM in the Current and Emerging DoD

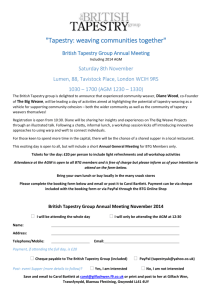

advertisement

Importance of CM/DM in the Current and Emerging DoD Product Support Environment 3 March, 2014 Dr. Marilyn T. Gaska, Chief Engineer and Michael “Bo” Gourley Logistics and Sustainment Corporate Engineering and Technology 1 Agenda • Performance Based Outcome Drivers • CM/DM Enablers Across the Life Cycle • CM/DM and the Digital Tapestry • Enablers for Capability Management 2 Performance Based Outcomes • Increased availability • Reduced down time • Improved affordability / cost management 3 History • Shared data and corporate history as 1990s enabler DARPA Initiative in Concurrent Engineering (DICE) • Integrated toolset within engineering • CAD/CAM systems and interfaces to manufacturing and logistics 4 DICE Star • Sharing information • Collocating people and programs • Integrating tools and services with frameworks • Coordinating the team • Capturing corporate history 5 Current Environment • DoD Integrated Product Support (IPS) elements • Importance of Chief Information Officer • Fleet management and agile development complexities • Initial applications for sustainment driving policy 6 DoD IPS Elements INTEGRATED PRODUCT SUPPORT Computer Resources Facilities & Infrastructure Manpower & Personnel Training & Training Support Support Equipment Technical Data Packaging, Handling, Storage &Transportation (PHS&T) & Management Maintenance Planning Supply Support Sustaining Engineering Design Interface Product Support Management Product Support is enabled by a package of 12 Integrated Product Support (IPS) elements designed to deliver system readiness and availability while optimizing system life cycle cost. Chief Information Officer Scope • DoD CIO Teri Takai, "Information is our greatest strategic asset" • Data management part of business architecture • System / data security / cyber focus • Cloud as an enabler for data sharing • Big data / analytics focus • Automatic Identification Technology (AIT) and Internet of Things Sustainment Driving Policy • OSD Product Support Assessment (PSA) & Proof Point Study confirmed PBL value • DoDI 5000.02 implements Better Buying Power 2.0 (“increase effective use of PBL”) • Focus on affordability across the life cycle The New Reality – Affordability and Resilience Systems 2020 Vision • Adversary can use commercial technologies and new tactics to rapidly alter the threat to US forces • DoD engineering, and business processes not structured for adaptability • New research, tools, pilot efforts needed to determine best methods for building adaptable defense systems • Need faster delivery of adaptable systems that are trusted, assured, reliable and interoperable Existing Gaps and Critical Needs • Gap: Lack of a Conceptual Design Environment • Gap: Lack of tools to integrate system modeling capabilities across domains • Gap: Lack of open, virtual and realistic environment for validation and producibility analysis • Need an integrated (i.e. cross discipline) framework for concept, design and analysis of systems based on standards, open architecture and existing COTS tool sets © Copyright 2011 Lockheed Martin Corporation Chris Oster, “The Lockheed Martin Digital Tapestry”, 2012 INCOSE Model Based Systems Engineering (MBSE) Workshop, Jacksonville, Florida. Emerging Environment • Revisiting 2013 Keynote • Next Gen 3D printing and additive manufacturing • Digital tapestry and Model Based Enterprise / Engineering (MBE) • NIST efforts in revitalizing manufacturing • Importance of standards / data quality / information management / DM/CM leadership 11 DoD Initiatives (Kratz, 2013) • New national security priorities • Joint Force 2020 • Lifecycle Management All these initiatives rely upon effective enterprise-wide information management • Performance Based Logistics (PBL) • Better Buying Power 2.0 3D Printing and 3D Simuation • 3D printing and 3D pathfinding simulation technology • Improve affordability and operational excellence throughout the entire lifecycle • LM Space Systems Company examples - 2014 13 Integrated Data Management for Digital Tapestry The Digital Tapestry Creating an Integrated Model Based Enterprise •LM, 2014 14 Digital Tapestry Transformation • “Digital tapestry” as seamless digital environment • Next-generation digital manufacturing technologies can extend throughout the lifecycle • Driven by integrated Model Based Engineering (MBE) tool set that keeps the digital data intact from conceptualization to realization • Requires underlying CM/DM 15 Importance of Standards • New industry standards vs. DoD • Supplier integration • Systems engineering • Design data and operational data management • Open systems profile to enable data interchange 16 Final Report MBE Subcommittee, Feb., 2011 17 Model Integration Through The Product Lifecycle Concept Development Technology Development Concept Refinement System CONOPS Model Production & Deployment Engineering & Manufacturing Development System Requirements 3D CAD Model Operations & Sustainment Producibility Model O&S Hub… TBD Mech. Analysis Model System Test Model Reliability Model System Architectur e Model System Cost Model Lifecycle Cost Model Bill of Materials Software Model Firmware / Elect. Model System Analysi s Model Integration of Major Hubs Achieved through Integrated Data Management Layer Integrated Data Management Layer Chris Oster, “The Lockheed Martin Digital Tapestry”, 2012 INCOSE Model Based Systems Engineering (MBSE) Workshop, Jacksonville, Florida. 18 Tom Hannon, “Evolving Lockheed Martin’s Engineering Practices Through the Creation of a Model‐centric Digital Tapestry”, NIST Model Based Enterprise Summit, 11-12 December, 2012 19 Data Quality / Information Management • Pay up front or pay more later in long term sustainment costs • Parallels for requirements / software • Technical debt for poor CM/DM • Cost of manual conversions / quality checks 20 CM/DM Leadership Opportunities • Early involvement during design • Part of product support management team • Support better decisions • Drive innovation made possible by CM/DM 21 Capability Management Vision • Engineering baseline management – digital data / configurations • Fielded baseline / asset management – where and what condition • Reliability / field feedback and root cause analysis • Modernization through spares / upgrades opportunities • Supplier / industrial base / customer integration 22 Next Steps • Accept the challenge • Demonstrate value proposition / business case • Be an integrated member of design / product support management / integrator team • Be ready to support the next generation 23