AJCC Presentation - Minerals Council of Australia

advertisement

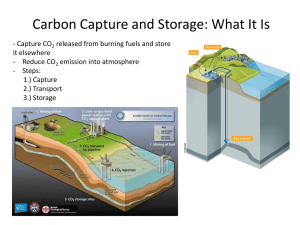

Australian Perspectives on Low Emissions Coal Technologies Mr Stewart Butel Managing Director, Wesfarmers Resources Limited Chairman, ACA Low Emissions Technologies Limited 16 October 2014 Ranking of Commodities in the world economy 12 months to mid 2013 Commodities MINED (‘000t) AVERAGE PRICE (US$/t) VALUE (US$ bn) Coal 7,800,000 85 663 Iron Ore 1,900,000 130 247 Copper 17,000 7,100 121 Gold 2.65 42,300,000 112 Bauxite 260,000 350 91 Nickel 1,700 14,000 24 Zinc 13,000 1,800 23 Platinum Group Metals 0.48 30,300,000 15 Diamonds 0.025 580,000,000 14 Lead 3,600 2,000 7 Top Ten Total 9,995,000 (132) 1,317 Source: IntierraRMG for the International Council on Mining and Metals 2 Fossil fuels will be important for a long time to come 3 050 years Total remaining recoverable Proven reserves resources Cumulative production to date 233 years 142 years 61 years Coal Natural gas 178 years 54 years Oil The world's remaining energy resources will not constrain the projected energy demand growth to 2035 & beyond, but large-scale investment is required Source: International Energy Agency, World Energy Outlook 2013 3 Australian Government’s Energy White Paper • December 2013 – Issues Paper released for public comment • September 2014 – Green Paper released • Late 2014 or early 2015 - Energy White Paper to be released “The IEA forecasts that fossil fuels will continue to provide a significant share of global stationary energy generation, which is largely driven by economic growth in emerging economies such as China and India. This means there will be a need to continue to develop lower emissions fossil fuel technologies such as carbon capture and storage (CCS) and take-up various high efficiency low emissions production techniques.” Australian Government’s Energy White Paper Issues Paper 4 Improve efficiency, then deploy CCS Source: IEA Insights Series (2013), 21st Century coal: advanced technology and global energy solutions 5 Global CCS Projects - Overview PROJECT Abu Dhabi Carbon Capture, Utilisation & Storage Project Boundary Dam FutureGen 2.0 Gorgon LNG Project Kemper County Petra Nova TECHNOLOGY CO2 capture (from Direct Reduction Iron facility) with Enhanced Oil Recovery (EOR) & storage Sub-critical coal Shell Cansolv PCC Retrofit LOCATION SCALE Abu Dhabi, United Arab Emirates 0.8 million tonnes per annum (MTPA) CO2 capture used for EOR Saskatchewan, Canada Note: Direct Reduction Iron facility already removes CO2. This stream is currently vented US$1.13 B World’s first large scale project STATUS Execution (expected capture from 2016) Commissioning Awaiting Final Investment Decision ( FID) Sub-critical coal Oxyfuel Retrofit Illinois, USA Pre-combustion capture / amine capture process Barrow Island, Western Australia 3.4 - 4.1 MTPA Saline Reservoir World's largest commercial-scale CO2 injection facility Construction (commence injection 2015) Mississippi, USA 582 MW 3.5 MTPA EOR US$5.5 B Construction (complete 2015) Texas, USA 250 MW 1.4 MTPA EOR IGCC coal Pre-combustion Newbuild Sub-critical coal Mitsubishi Heavy Industries PCC Retrofit US$1.65 B US$2 B Sinopec Shengli Fluidised bed coal PCC Retrofit Shandong, China White Rose Supercritical coal Oxyfuel Newbuild North Yorkshire, UK Gasification Pre-combustion Newbuild Shaanxi, China Yanchang Integrated CCS 110 MW 1 MTPA EOR 200 MW 1.1 MTPA Saline Reservoir COST US$122.5 M for CO2 dehydration & compression facility only ~250 MW 1 MTPA EOR 426 MW 2 MTPA Depleted Oilfield 0.46 MTPA from chemical production EOR US$469 M Costs per USDoE World's largest post-combustion CO2 capture (PCC) system for an EOR project Construction (commenced July 2014) To be finalised in Front End Engineering & Design (FEED) FEED Awaiting FID To be defined as part of FEED Define Stage (FEED) To be defined as part of FEED First capture phase began in 2012 and pilot injection testing under way Define Stage 6 COAL21 Fund World-first voluntary levy on coal producers Facilitating early demonstration of low emissions coal technologies Targeted co-investment with other stakeholders (Government, electricity generators, equipment suppliers, other industry investors) Strategic approach: • Proving storage in Australia • Engagement with projects actually sequestering CO2 • Promoting multi-sector involvement in CCS • Promoting community acceptance of CCS and coal’s ongoing use • Reducing greenhouse gas emissions from coal mining operations 7 Examples of COAL21 Fund Projects 1. Capture projects 2. Storage projects 3. Research and Development (R&D) projects 4. Fugitive emissions projects 8 Demonstration project - Callide Oxyfuel Objective • Retrofit oxy-fuel technology to 30MW boiler at Callide A power station • Operate for 2 years Status • Plant commissioning completed Dec 2012 • 8,000 hours operation in full oxy mode • Complete demonstration by Feb 2015 9 Storage Projects Potential CO2 Storage Areas – Qld Qld Carbon Geostorage Initiative Objective • Identify and assess sites for the safe, long-term geological storage of CO2 in Queensland Surat Basin Status • Funding commitments being confirmed NSW Storage Assessment Objective • Identify and assess sites for the safe, long-term geological storage of CO2 in NSW Status • Six wells drilled in key geological basins • Data analysis in progress Potential CO2 Storage Areas – NSW Otway R&D • 65,000 tonnes CO2 stored in depleted gas field • Ongoing R&D on aquifer storage 10 Storage Projects (continued) Carbon Transport and Storage Company (CTSCo) Surat Basin Integrated CCS project - Feasibility Study Objective • Demonstration to safely and securely sequester CO2 into the precipice sandstone of the Surat Basin , Queensland Status • Feasibility Study Stage to commence shortly Surat Basin Research & Development Australian National Low Emissions Coal (ANLEC) R&D work Objective • Broad based applied R&D program covering key CO2 capture and geological storage technologies in support of demonstration projects Status • All programs progressing well Micronised Refined Coal fuel for a Direct Injection Carbon Engine (MRC-DICE) Objective • Atomisation and combustion tests in a 1MW scale test engine Status • Funding commitments now confirmed 12 Fugitive Emissions Objective • Demonstrate safe deployment of Ventilation Air Methane (VAM) abatement technologies at underground coal mines Status • Initial high level risk assessment complete • Suite of four projects initiated World’s first VAM demonstration Power Plant at BHP Billiton’s West Cliff Colliery (MEGTEC VOCSIDISER® technology) Demonstration of Corkys VAM – Regenerative After Burner (VAM-RAB®) technology at Centennial Mandalong mine 13 Concluding comments • Coal extraction and utilisation are set to continue to expand over the next two decades • Coal has an important role in a secure and sustainable energy future but it will ultimately need to be a low carbon future • Increasingly, the focus for coal and other fossil fuel use will be China, India and the rest of Asia • CCS is not a coal technology but one relevant to all fossil fuels and heavy industrial plant • To reduce the cost of CCS we need to incentivise high efficiency and low emissions technologies rather than just focus on CCS • Demonstration, R&D and knowledge transfer activities will remain important • For Australia storage is a priority as well as continued contribution to the international CCS R&D and demonstration effort. 14