UNION QUALITY PLASTICS LTD.

advertisement

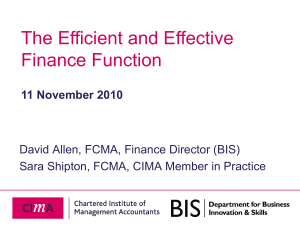

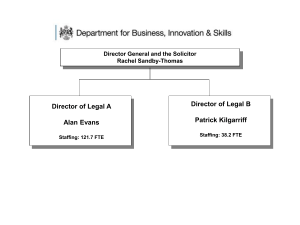

UNION QUALITY PLASTICS LTD. Putting Quality First Since 1981 Introduction and History • M/S Union Quality Plastics were established in the year 1981 and went public in 1992 • We manufacture high quality HDPE/LDPE tarpaulins. • This is one of the Prime businesses in the portfolio of Kathawala holdings • Our head office is in Mumbai and our manufacturing facility is located in Gujarat • Our annual revenue is Rs 25 CR (USD 5.5 million) • PlexCouncil award for best exporter in 1999/2000 • Flat Organization for effective decision making. • ISO 9001-200 QMS company 2 VISION AND OPERATING PRINCIPLES VISION • To be a world class plastic and polymer facility with the ability to constantly innovate to deliver solutions that exceed our customers expectations OPERATING PRINCIPLES • Be quality conscious in everything we do • Provide excellent value and prompt services • Provide appropriate end-to-end solutions • Ensure inclusive growth for all our employees • Care of the environment 3 STRUCTURE AND MANAGEMENT TEAM • Team includes: • Zuzar Kathawala, Managing Director, an entrepreneur with 35 yrs of experience running a range of businesses. • Sunil Tripathi, CEO, who has built on his plastic engineering degree 15 yrs of manufacturing experience • Jayraman, Accounts, a veteran of 40 years in the field • Rajesh Tayde, Quality Assurance, experienced in managing quality systems to maintain standards and guidelines given my organizations such as ISO/ISI/BIS. • Mr Qusai Kathawala,expertise in R&D • Mr Noel Selvaraj,MBA in Marketing,currently handling clients internationally and Corporates. 4 BIS Products BIS 15351 HDPE Geomembrane for canal lining Application BIS 7903 HDPE Tarpaulin used By farmers Tarpaulin Products Various Application uses of tarp • • • • • • • • • • Cap covers Bricks Industries Chemical Industries Sugar Industries Textile/Spinning Mills Shipping companies Steel Industries/Steel Plants (to cover coals) Machinery Manufacturers Food Industries Agriculture applications Poultry Industry • • • • • • • • • • • Pound lining Floor lining Truck covers Poultry curtains Machinery covers Fumigation covers Railway wagon cover Automobile covering Swimming pool cover Construction sites cover Protecting grain heaps during cultivation • Covering green house Tarpaulin Processing Tape Extrusion Weaving Laminating Slitting/Cutting/Rewinding Heat sealing and Rope Sealing Tarpaulin Finishing and Packaging 8 PRODUCTION PROCESS EXTRUSION Raw Materials: HDPE + Antifab + Master Batch Equipment: 1. KTK-90mm Windsor Tape 2.Kolsite 90mm Tape plant. Capacity 150 tons/month WEAVING Equipment: 1. HDN-4 (LOHIA STARLINGER), 18 nos.: up to 60” flat width with variable mesh size 2. HDN-6 (LOHIA STARLINGER/GCL BANGLORE), 11 nos.: up to 104” flat width 3. HDN-8 (GCL BANGLORE), 2 nos.: up to 144” flat width Capacity 60 tons/month LAMINATION Raw Materials for coating: LDP + LLDPE + Master Batch Equipment: Unit A: 98” Die opening for up to 96” fabric Unit B-74” Die opening for up to 72” fabric Unit C-52” Die opening for up to 50” fabric Also available--craft paper lamination: -sandwich material which acts like a Vapor corrosion 9 inhibitor (VCI) PRODUCTION PROCESS (contd.) TARPAULIN Equipment: •5 sealing machine that can produce sizes ranging from [6’ x 6’] to [100’ x 100’] •4 automatic eyeleting machines for efficient finishing Capacity:175 tons/month. STITCHING To make bags for sugar, foam, textile, chemical, grain & other industries Capacity: 100,000 bags/month 10 GREEN INITIATIVES 11 Go Green • Sharp supervision, use of quality raw material, proper handling system and use of trolleys for wastage collection • To reduce wastage during extraction, weaving, lamination & stitching, we ensure that we : – use correct additives & master batches, – complete regular maintenance, – implement tight quality control and supervision during material inward & process stages • Appropriate disposal of scrap for other uses. • Obtaining ISO 14001 certification. RS Millions Sales 350 300 250 200 Export 150 Local 100 50 0 2008-09 2009-10 2010-11 Market Share Export, 30% Local, 70% INTERNATIONAL NGO CLIENTS : • UNICEF • UNHCR • POLYPACK USA • MANSOOR SAFETY PRODUCT DUBAI: Sizes:[60’ * 60’] tarpaulin for different field Sizes:12’ x 15’ -150GSM & 4mtr x 5mtr- 190GSM tarpaulin, large individual orders e.g. 10000 pieces. Sizes: 4mtr x 5mtr, 12 x 12 mesh, 20000 pieces [80 Tons] Sizes: 4mtr x 5mtr, 12 x 12 mesh application • TECHNO RELIEF KENYA • JOMPISA SPAIN 15 THANK YOU! 16