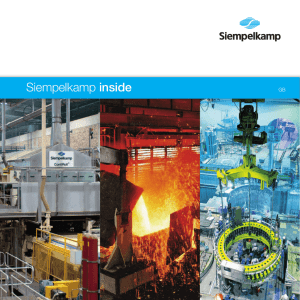

Presentation - Litostroj Ravne Ltd.

advertisement

Litostroj Ravne Ltd. Koroška cesta 15 2390 Ravne na Koroškem Slovenia TRADITION, POWER QUALITY , INNOVATION LITOSTROJ RAVNE IS A MEMBER OF LITOSTROJ GROUP 1 LITOSTROJ GROUP 2 Litostroj Ravne – History and company profile • • • • • • • • • • • • • Is located in Ravne na Koroškem (town has more than 380 years industrial history ). Presses (Brand Name „RAVNE“) have 45 years long history. 1620 1969 1970-71 1971 1985 2008 2010 2011 Beginning of steelmaking in Ravne. Construction of first press. Cooperation with Weingarten. First press was exported to Germany. First press was exported to U.S. Became part of Litostroj Group First Precise blanking press. First Servodrive press. Number of employees : 200 Representatives on the markets 18 km to highway, 60 km from airport Port : Luka Koper Experience of generations 3 RAVNE Presses– Worldwide brand MORE THAN 1.500 REFERENCES, MORE THAN 150 CUSTOMERS TARGET INDUSTRIES AUTOMOTIVE INDUSTRY ; HOME APPLIANCE INDUSTRY; TOOL AND DIE INDUSTRY; ELECTRO INDUSTRY. 4 LITOSTROJ RAVNE – ADVANTAGES: Mechanical and Hydraulic Presses up to 40.000 kN and bed width up to 8 m. Optimal solution for customer needs and customer specific design. Innovative and proven technology. Robust basic construction. Precision operation (Slide and Bed have low deflection 0,08mm/m ) Flexibility. Short delivery time . Complete quotation (design, mechanical and electro development, assembly, spare parts & service all life time presses). In Ravne : • • • • Development (mechanical, electro) Production of main parts products(forged and welded parts, steel casting) Assembly Service 5 MAIN PRODUCTION PROGRAM Custom made Mechanical and Hidraulic Presses RAVNE Single Presses RAVNE Transfer Presses RAVNE Tandem Press Line SC, SE, SL RAVNE Progressive Die 6 RAVNE Transfer presses SE4 -1000 – 50 – 24,4 Automation: 3 axis servo transfer Production: car sheet metal parts 30 SPM SE4 -2500 - 61 – 24,4 25 SPM SE4 -1000 – 36 – 15 45 SPM Production: Transmission parts Automation: 3 axis servo transfer SE4 -2000 - 60 – 15 25 SPM Production: Automatic speed hosing 7 RAVNE Tandem press line SE2 1000-27-15, SE2 800-27-15, SE2 500-27-15, SE2 400-27-15 Production: Gas tanks SE2 800-27-15, SE2 500-27-15, SE2 400-27-15 Production: Suspension parts Automation: Robots 16 SPM SE4-1500-144-96 SE4-1000-144-84 , SE4-800-144-84 Automation: Robots Production: Outer car parts 12 SPM 8 RAVNE Blanking lines Press SC2-600-24-16 with line (decoiler, double straighteener, components for material flow, line for fast die change) The advantages: • Achieved straighteness • High level of productivity: up to 140 pcs/min • One cutting operation is less –fewer presses RAVNE Progressive die presses SC2 -500-20-14 Automation: Feeding line PSN 400 Production: Structure parts 80 SPM SE4 -1600-240-108 Production: Structure parts 44 SPM Progressive Die presses by Litostroj Ravne achieve stroking rates up to 90 SPM They are available as link drive presses in capacities from 3.000 to 30.000 kN. 10 RAVNE REFERENCES 11 ADDITIONAL PRODUCTION PROGRAM Disassembling Relocation UPGRADE /REFURBISHMENT ANY PRESSES Assembling Spare parts & Service 12 13 UPGRADES – Quick die change is suitable for TANDEM LINES without rolling bolsters. With specially designed system the dies are changed in one interval on all presses. Die change time can be lowered under three minutes. The system was developed for companies that CHANGE DIES MANY TIMES PER SHIFT. 14 Slide guides ON-SITE refurbishment Ravne special equipment allows us to do the refurbishment on the spot, even ON PRESSES WITH FIXED SLIDE GUIDES. Machining without frame disassembling and without drilling or any damage to the uprights. Quality of machining is controlled with 3 measuring system. The result is guide flatnes in tolerance + - 0,02mm/m. 15 RAVNE Presses „Best price/performance“ THANK YOU FOR ATTENTION! www.litostrojravne.com 16