Click here to

advertisement

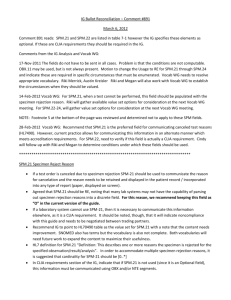

Project ManagementNot only a Life Skill But a Life Changing Skill Thomas Chacko PM- Profession & Life Skill • PM techniques can be applied by non-project managers to help implement change • Set of knowledge, profession and career choice • Can be learned and applied by a variety of groups, including school students • Helps to step into leadership roles • Can apply the techniques in real life situations PM- in EPC Projects • • • • • • • Engineering, Procurement, Construction (EPC) All disciplines of Engineering Longer duration with several players Vast Interface, logistics and obstacles Varied and huge resources- men and material Location specific Subject to clearances, legalities, external factors PM-Common World Language “Project Management can be used as a common language around the world to help bring people together and enable organizations to prosper.” Philip Diab (Past Chairman PMI) Life Changing Project • A major EPC Project linked to Infrastructure, changes the area, economy and life of people • Public sector Projects are examplesGoshree bridges, Delhi Metro • BPCL Kochi Refinery recently implemented 2 major Projects – Crude Oil Receipt Facilities (SPM) in Puthu Vypeen and – Capacity Expansion and Modernization Project Phase II (CEMP II) in the Refinery Life Changing Project • SPM Project was dogged with problems right from conceptualization. • Project was all about overcoming obstacles. • A challenge during implementation • A life long memory on completion. • Affected the lives of many people who directly or indirectly benefited or did not. • For the benefited, it changed their lives and are examples of a Life changing Project. CRUDE OIL RECEIPT FACILITIES (SPM) PROJECT BPCL KOCHI REFINERY TC 7 CONCEPT KOCHI REFINERY WAS BRINGING CRUDE OIL THROUGH COCHIN PORT TRUST’S CRUDE OIL TERMINAL (COT) THE DRAUGHT AVAILABLE AT COT (11.6m) LIMITED SHIP CAPACITY TO 60000 MT. WITH CHEAPER CRUDE BECOMING AVAILABLE FROM SOUTH AMERICA AND AFRICA, USE OF VLCC (Very Large Crude Carriers) CONSIDERABLY REDUCED TRANSPORTATION COSTS. VLCC REQUIRES A DRAUGHT OF 29 M, SETTING UP A SPM (Single Point (Buoy) Mooring –TERMINAL BECAME A NECESSITY. VARIOUS LOCATIONS CONSIDERED FROM 2000 PUTHU VYPEEN FINALIZED BASED ON MOU WITH CPT IN 2005 LAND ON LEASE FROM CPT, SPM LOCATION, WHARFAGE CHARGES AND LAND PIPE ROUTES AGREED UPON. Crude Oil Receipt Facilities Project TC 8 SPM SYSTEM FLOW DIAGRAM Existing line from COT SPM Hose Crude transfer pumps PLEM Refinery corridor VLCC (3,00,000 DWT max) To Refinery Existing line Offshore piping (48” dia 20 km) OFFSHORE AREA Onshore /Backwater cross country piping (30’’ dia 10 km) Crude Oil Tanks 79 m dia X 18 m Ht STF AREA TC CCPL PIPE LINE 9 Aerial view of Puthu Vypeen To Refinery Cross country pipeline STF Sub sea pipeline TC SPM 10 TC 11 SALIENT DETAILS • Project Approved cost- Rs 820 crores Actual Executed Cost • • • • - Rs 760 crores Pre Project activities commenced 70 ha land handed over by CPT Project Approval Date Approved Completion date - Mar 2005 - Jul 2005 - Sep 2005 - May 2007 – Actual Completion (27 months) - Nov 2007 • Conventional EPMC – PMC- INTEC, Kula Lumpur with FEDO as Associate for Onshore jobs TC 12 SCOPE OF MAJOR JOBS-OFFSHORE GEOTECHNICAL & BATHYMETRICAL SURVEYS DESIGN, SUPPLY SPM (250 MT) & PLEM (175 MT)- Assembled at Batam, Indonesia, transported in a dedicated ship to Cochin SUBMARINE & FLOATING HOSES ITALY 48” PIPES API 5L X 65 20.6 mm MUNDRA thick with CTE coating – 1650 nos Slabs from Mexico, rolled into each 12M long plates in Romania and shipped to Kandla. CONCRETE COATING OF PIPES (90-120 MM THICK) MUNDRA TC 13 SCOPE OF MAJOR JOBS-STF EARTH FILLING BY ADDL 3 M (AVG) TANK FOUNDATIONS- 3 NOS with 1360 PILES EACH 900 MM DIA & 50-60M LONG BUILDINGS , ROADS, COMPOUND WALL (5 KM) CEMENT SUPPLY- 38000 MT REINFORCEMENT STEEL SUPPLY- 4500 MT TANK PLATES- 8 T0 37 MM THICK- 5000 MT PUMPS TANK CONSTRUCTION- 3NOS EACH 79 M DIA & 18 M HIGH WITH FLOATING ROOF TERMINAL PIPING EFFLUENT TREATMENT PLANT FIRE FIGHTING FACILITIES ELECTRICAL SUPPLY & SUBSTATION TC 14 SCOPE OF MAJOR JOBS- CROSS COUNTRYPIPE LINE 30” API 5L PIPE SUPPLY- 10 KM BACK WATER CROSSINGS- 4 NOS – 4 KM LONG HORIZONTAL DIRECTIONAL DRILLING METHOD (HDD) ONSHORE PIPE LAYING - THROUGH VYPEEN AREA- 4 KM - THROUGH CITY AREA - 2KM TC 15 First Tanker Berthing at SPM Buoy TC 16 Uniqueness of the Project First Investment after opening of Goshree bridges in the underdeveloped Puthu Vypeen area First Project over Rs. 500 cr in Kerala after 1990 First Offshore job off the Arabian Sea coast STF construction on accreted land Water jetting for seabed dredging HDD for buried pipe lines Started as KRL and ended as BPCL Project Annual savings of about Rs. 120 Cr Completed in 27 months and commissioned next day. TC 17 Obstacles faced • • • • • • • • • • • Resistance from Fishing Community, blockades Militant Labor in area – 152 days lost Communally and politically sensitive issues Physical threats, loading/unloading disputes Tsunami hit the Vypeen coast in Dec 2004 6 lakh cum of Earth for filling to come from 45 km Narrow road approach; Logistics for Material Limited crane facility at Cochin Port 6 months unfavorable weather (May-Oct) Poor soil conditions Pipeline across backwater &through heart of city TC 18 How we overcame-1 • Priority in befriending local inhabitants and earning their acceptance and trust. • Unskilled locals were also employed in construction. • Continued interaction with unions, Panchayat • Helped in improving schools, solving flooding • Close cooperation with CPT and District Administration, Police • Spent Rs 16 cr on CSR activities thro transparent means involving local and district authorities • Changed STF entry to South side to avoid blockade TC 19 How we overcame- 2 • Changed pipe routing thro new CPT road making the road open for transportation • Excavated earth from narrow north end to fill south side where construction was focused • Detailed study made and action for optimized logistics and handling heavy loads • Pile foundations used and sea wall built to resist tsunami waves • HDD used for water crossing and through city road • New interconnection made to existing crude line TC 20 Still …the Unexpected • 4 hours after inauguration in Sep 2005, a child drowned in a lagoon inside STF. • One fatal accident during Pile driving for tank • 70 km/hr winds lash STF site in 2006 • Offshore accident on 1st May 07 during Pile driving resulting in work abandonment • Damaging Unknown Sewer lines in city • Delay by Railways in clearing crossing at Ekm Jn • Cyclone “Gonu” in Arabian sea in Oct 2007. TC 21 Factors for Success in PM-Investor view Resources Communication Control Planning Creativity Team effort Functional vs Project Functional Manager Project Manager Approach Analyst Generalist Style Expert Facilitator Technology & Resources Results Area Whole Responsibility Vision Skills/Factors that can change lives • • • • • • • • Influence others Create values that will be respected Carry the support of your organization Be Positive-Keep moving forward- never give up Use technology to overcome obstacles Have back up plans ready Be realistic -street smart Have the bird’s eye view always in your mind Life Changing Projects- Core Skills to Succeed • Credibility Technical and Administrative • Leadership Along with Management Style • Sensitivity Conflict Resolution, Negotiation • Ability to handle stress Ups and downs Project Success “Ultimately the SPM Project Success was achieved by the Team winning the hearts of the local people, converting their hostility into creative contribution, synchronizing with the larger national objective of development.” Yes their lives changed; so did ours; all for the better.