presentation ppt

advertisement

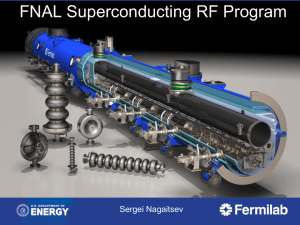

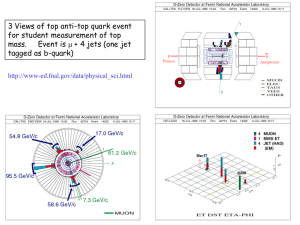

Superconducting RF Cavity/Cryomodule Development at Fermilab (Industrialization) C.M. Ginsburg (FNAL) Proton Accelerators for Science and Innovation 2nd Annual Meeting Rutherford Appleton Laboratory, UK 3-5.April 2013 Overview Fermilab SRF activity at FNAL/ANL is in support of Project X, ILC, or other future SRF projects Explicitly includes industrial development, and associated R&D for improved performance and reliability, and reduced cost Infrastructure availability and personnel development permit the development of industrial partners for SRF cavities and cryomodules FNAL philosophy: the laboratory does not duplicate activity or compete with industrial capability Industry can provide most materials and services more quickly at lower cost Exceptions involve substantial infrastructure, e.g., cryogenic systems Most of the industrialization focus has been for the ILC, so this talk will be weighted toward ILC (electron) technology Most conclusions are broadly applicable to other SRF projects ...Proton accelerators in particular 5.Apr. 2013 Ginsburg (FNAL) 2nd PASI Workshop 2 Outline Fermilab Cavity vendor development Cavity processing vendor development Cavity and cryomodule value engineering Cryomodule assembly Not yet industrialized in the US; XFEL example will be instructive Existing industrialization workshops (ILC) 5.Apr. 2013 Ginsburg (FNAL) 2nd PASI Workshop 3 Bare cavity sequence Fermilab Each inspection, processing and test step is recorded in an electronic traveler For large projects like XFEL, it may make sense to dress cavities before vertical test 5.Apr. 2013 4 Ginsburg Ginsburg (FNAL) PASI Workshop - NGLS Review Feb 5-8,2nd 2013 4 Cavity dressing sequence 5.Apr. 2013 Ginsburg (FNAL) 2nd PASI Workshop Fermilab 5 CM assembly sequence (part 1) Receive dressed cavities at CAFMP9 Fermilab Receive peripheral parts Assemble dressed Cavities to form a String in the Cavity String Assembly Area (Clean Room) Install String Assembly to Cold Mass in the Cold Mass Assembly Area Transport the Cold Mass to CAF-ICB 5.Apr. 2013 Ginsburg (FNAL) 2nd PASI Workshop 6 CM assembly sequence (part 2) Fermilab Install the Cold Mass back to the Cold Mass Assembly Fixture in Cold Mass Assembly Area Align Cavity String to the Cold Mass Support Install the String assembly with the cold mass into the Vacuum vessel in the Vacuum Vessel Assembly area Ship Completed Cryomodule to ILCTANML for testing 5.Apr. 2013 Ginsburg (FNAL) 2nd PASI Workshop 7 ILC cavity: international effort Fermilab • ILC cavity fabricators – – – – – – – – Research Instruments (Germany) Zanon (Italy) Advanced Energy Systems (US) Niowave and Roark (US) PAVAC (Canada/US) Mitsubishi Heavy Industries (Japan) Toshiba (Japan) Hitachi (Japan) • ILC cavity processing facilities – – – – – DESY Jefferson Lab KEK Fermilab/Argonne joint facility (Industrial processing facilities: RI, AES, Zanon) • Results from past 3 years have been collected in worldwide database, as a means to further track progress and provide input to ILC machine design 5.Apr. 2013 8 Ginsburg Ginsburg (FNAL) PASI Workshop - NGLS Review Feb 5-8,2nd 2013 8 “Up-to-second-pass” ILC Production Yield Plot - Method • Cavity from vendors who have manufactured a cavity that has surpassed 35MV/m in vertical test: – • • • • • ACCEL or ZANON or (AES SN>=5) or (MHI SN>=12) Fine-grain cavity Use the first successful (= no system problem) test Standard EP processing: no BCP, no experimental processes (Ignore test limitation) Second pass – if (Eacc(1st successful test)<35 MV/m) then • if (2nd successful test exists) then – plot 2nd test gradient • else – plot nothing [assume 2nd test didn’t happen yet] • – else • – 5.Apr. 2013 endif plot 1st successful test gradient endif Ginsburg (FNAL) 2nd PASI Workshop 9 International cavities from established vendors using established processes 2nd pass yield for >35 MV/m for integrated sample is (57 +- 8)% for 2010-2012 alone is (69 +- 13)% 5.Apr. 2013 Ginsburg (FNAL) 2nd PASI Ginsburg (FNAL) 2ndWorkshop PASI Workshop C.M. GInsburg et al., KILC12, Daegu, S. Korea http://ilcagenda.linearcollider.org/contributionDisplay.py?contribId=85&sessionId=36&confId=5414 2nd pass 1st pass ILC Cavity Performance Benchmark Fermilab 10 Gradient Summary • • • Good progress worldwide in cavity production, processing, and test AES has been qualified as an ILC cavity vendor during this activity Progress is a partnership between industry and laboratories, results are dependent on both performing well – – • Utility of XFEL test data for ILC will be limited by XFEL requirements, but huge data set Efforts to exceed ILC gradient spec will continue – • constant vigilance required afterwards to stay there Yield statistics to the ILC specification show improvement with time – • Scars, pits, stains, dirt and residue introduced at different steps Early defects are not typically overcome by the standard processing steps The typical learning curve at each company requires a ‘few’ cavities – • Fermilab Field emission prevention at all gradients remains important Laboratory processing and test facilities are coming up to speed, recent throughput at Fermilab for instance is very good 5.Apr. 2013 Ginsburg (FNAL) 2nd PASI Workshop 11 New Vendor Development: PAVAC Fermilab Canadian company with new facility in Batavia 1-cells: 6 fine-grain cavities fabricated – Half use “smart-”bells TE1PAV001-3 • First weld together half-cells, then add beamtubes – Half use dumb-bells – TE1PAV004-006 • First weld each half-cell to a beamtube, then weld together • “smart bell” cavities exhibited multipacting ~18-22 MV/m possibly due to unusual shape 9-cells: 10 fine-grain cavities were ordered; order later changed to 650 MHz 5.Apr. 2013 Ginsburg (FNAL) 2nd PASI Workshop TE1PAV001 12 New Vendor Development: Niowave-Roark Fermilab Six 1-cells tested extensively from 2008 – BCP/VT @Cornell, some had add’l prep/tests – Useful information learned, e.g., defect on die – Primarily being used for commissioning and materials studies now Six 9-cells received QC shows fabrication is not yet as stable as other vendors Performance is moderate Tumbling R&D 5.Apr. 2013 Ginsburg (FNAL) 2nd PASI Workshop 13 Vendor Surface Processing Fermilab • NR flash BCP’d the six 9-cells – insufficient data to comment • AES flash BCP’d the latest batch of six 9-cell cavities – all show some pitting but performance is typically good – Does BCP cause the pitting? • Process not well controlled, e.g., acid flow too fast • Pitting worse on lower surface than upper – Does material cause the pitting? • Pits re-emerge after tumbling • R&D on sheet corners anticipated • RI did bulk EP on half of the latest batch (six of twelve) – Performance more likely to improve after heavier “light” EP • So far, no performance advantage, but potential advantage justifies a controlled promotion of industrial processing – AES has a new EP machine – Process was qualified on a 1-cell cavity – AES to bulk EP six cavities this year 5.Apr. 2013 Ginsburg (FNAL) 2nd PASI Workshop 14 Industrial Surface Processing 5.Apr. 2013 Ginsburg (FNAL) 2nd PASI Workshop Fermilab 15 Cavities Flash BCP’d at Vendor Fermilab TB9AES013: Pits observed in all three images, but generally enhanced by EP. Pits are not restricted to just the equator weld or the heat affected zone. 1) Optical inspection of equator weld before EP 2) Photo before electropolishing. 3) Photo after electropolishing ( ~ 120 microns removed) 1 2 3 5.Apr. 2013 Ginsburg (FNAL) 2nd PASI Workshop 16 Cavities Bulk-EP at Vendor Fermilab RI bulk-EP removal amount (um) 133 153 138 130 152 140 * *KEK grinding repair 5.Apr. 2013 Ginsburg (FNAL) 2nd PASI Workshop 17 Value Engineering: FNAL Dressed Cavity Cavity Costs 6-13% Fermilab Dressed Elliptical SRF Cavity Fully Burdened Cost Breakdown *Fermilab Costs 11-13% 63-71% 11-12% Second Pass HPR Reprocess • Processing is ~ 13% of the cost of a dressed cavity 5.Apr. 18 2013 Ginsburg Ginsburg (FNAL) PASI Workshop - NGLS Review Feb 5-8,2nd 2013 18 Value Engineering: FNAL/ANL Cavity Processing Fermilab Fully Burdened Cost Breakdown *Fermilab Costs • 26%*13% =4% of the cost of a dressed cavity is material removal • Processing costs dominated by touch labor Estimated FNAL Cost Breakdown 5.Apr. 19 2013 Ginsburg Ginsburg (FNAL) PASI Workshop - NGLS Review Feb 5-8,2nd 2013 19 Value Engineering: FNAL ILC Cryomodule Fermilab 15% 43% 26% ILC Type-3 Cryomodule M&S actual cost 5.Apr. 20 2013 Ginsburg Ginsburg (FNAL) PASI Workshop - NGLS Review Feb 5-8,2nd 2013 20 FNAL CM Assembly Throughput Fermilab 14 days 13 days 9 days 14 days 8 days 5.Apr. 2013 Ginsburg (FNAL) 2nd PASI Workshop 21 FNAL Cryomodule Assembly Fermilab • CAF infrastructure is fully functional for the 1.3 GHz pulsed cryomodule assembly. • We have assembled two 1.3 GHz and one 3.9 GHz cryomodules at CAF. Our experience is still too limited to fully assess each step of the assembly and make optimization. • New assembly tooling will be needed to assemble the 325 and 650 MHz cryomodules but the main infrastructure of the CAF looks adequate to assemble these cryomodules. • Cavity dressing/qualification and assembly components preparation for cryomodule assembly will probably require some automation in order to increase the throughput for future projects. • Cryomodule assembly throughput requirements will dictate hiring and training technicians. Training required for CM assembly is lengthy, especially for cleanroom work. 5.Apr. 2013 Ginsburg (FNAL) 2nd PASI Workshop 22 ILC Industrialization Workshops Fermilab • Two ILC industrialization workshops took place, with substantial industrial and lab participation – PAC10 Kyoto satellite meeting • http://ilcagenda.linearcollider.org/conferenceDisplay.py?confId=4530 – SRF2011 Chicago satellite meeting • http://ilcagenda.linearcollider.org/conferenceDisplay.py?confId=5182 • Discussion topics: niobium material, cavity fabrication, industry regional differences, CM fabrication • Webpages provide a useful resource 5.Apr. 2013 Ginsburg (FNAL) 2nd PASI Workshop 23 Fermilab 5.Apr. 2013 Ginsburg (FNAL) 2nd PASI Workshop 24 Summary Fermilab ILC has provided a great opportunity for US SRF industrial development Cavity vendor development Cavity processing vendor development Cavity and cryomodule value engineering exercises are ongoing for future projects Existing industrialization workshops (ILC) provide a resource for understanding cost reduction targets 5.Apr. 2013 Ginsburg (FNAL) 2nd PASI Workshop 25 Acknowledgements Fermilab • Many thanks to our Fermilab, national, and international collaborators for their hard work and excellent contributions to the cavity and cryomodule development presented here • Material for this presentation was provided by T. Arkan, J. Kerby*, A. Rowe (FNAL). *now at Argonne National Laboratory 5.Apr. 2013 Ginsburg (FNAL) 2nd PASI Workshop 26