slides - Institute for Systems Research

advertisement

Systems Engineering of GM’s

Global EE / SW Product Line

Dr. Joseph D’Ambrosio

ECS Process, Methods,

& Tools

GLOBAL RESEARCH &

DEVELOPMENT

Outline

¶

Introduction

¶

Embedded Systems Development at GM

¶

Product Line Engineering

¶

Additional Topics

About Me – Dr. Joseph D’Ambrosio

¶

Automotive Industry 25+ years

– GM, Delphi

– Research, Advance Development,

Product Development

– Model-Based Sys. & SW

Development, Safety-Critical

Systems, Cyber Security, By-Wire

Systems, Vehicle Control Systems,

VLSI Design & Tools, Testing

– ISO Technical Expert – ISO 26262

Automotive Functional Safety

Standard

¶

PhD University of Michigan – EE

Design Methods / Optimization

¶

50+ publications, 7 patents

Warren, MI

SHANGHAI, CHINA

PALO ALTO, CA

HERZLIYA, ISRAEL

BIG THINGS ARE COMING…

There Has Never Been A

Better Time To Be An

AUTOMOTIVE

EMBEDDED SYSTEM

ENGINEER

AND WE HAVE A FRONT ROW SEAT!

Energized by

Petroleum

Energized by Biofuels,

Electricity, and

Hydrogen

Powered Mechanically by

Internal Combustion

Engine

Powered Electrically by

Electric Motors

Controlled

Mechanically

Controlled

Electronically

Stand-alone

“Connected”

Totally Dependence

on the Driver

Semi/Full Autonomous

Driving

Vehicle Sized for Max

Use – People and

Cargo

Vehicle Tailored to

Specific Use

CADILLAC DRIVER ASSISTANCE /

ACTIVE SAFETY

Package 1 – “Driver Awareness Package”

Package 2 – “Driver Assist Package”

Cadillac ATS

Cadillac XTS

Cadillac SRX

Cadillac ATS

Cadillac XTS

Cadillac SRX

Front Camera

Ultrasonic Sensors

Short Range Radars

Long/Mid Range Radar

Short Range Radars

Front Camera

Rear Camera

Ultrasonic Sensors

Lane Departure Warning

Safety Alert Seat

Forward Collision Alert

Side Blind-Zone Alert

Rear Cross-Traffic Alert

Haptic Safety Alert Seat Feedback

Also includes:

Rear Vision Camera

Front & Rear Park Assist

Short Range Radars

Short Range Radar

Rear Camera

Package 1 plus:

Full Speed-Range ACC (Stop w/Go Notifier)

Auto Collision Preparation (includes Collision

Imminent Braking)

Low-Speed Front/Rear Automatic Braking

(Emergency Braking to Avoid Contact)

7

7

Improving Safety with V2V/V2X

COMMUNICATIONS

+ “Warning”

“Warning”

AUTONOMOUS DRIVING

Forward Vision System

– Lane tracking

– Object detection

– Far IR Capability

ShortRange

Sensors Long-Range

Scanning

Sensor

ShortRange

Long- Sensors

Range

Sensors

Rear Vision SystemEnhanced

– Object detection

Digital Map

– Far IR Capability

System

Forward Vision System

Ultrasonic

Sensors

Ultrasonic

Sensors

Dedicated Short-Range

Communication + GPS (V2V)

EN-V VIDEO

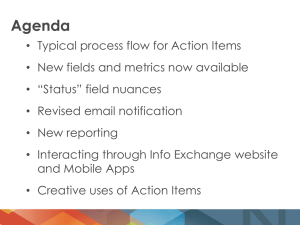

Outline

¶

Introduction

¶

Embedded Systems Development at GM

¶

Product Line Engineering

¶

Additional Topics

OUR CONTRIBUTION…

History of GM Automotive

Computing

•

First Embedded Controllers

• 1977 – First GM production automotive microcontroller

•

Electronic spark timing

• 1981 – All GM North American vehicles use microcontrollerbased engine controls

•

•

•

3.9M vehicles total, 22K ECMs per day manufacturing rate

50,000 lines of assembly code, MC6800 – 8-bit 2 Mhz,

Comparison against PC industry

PC Sales

(in 1000s)

• Today

•

•

•

40-70 microcontrollers per vehicle

400K Lines of C Code for an engine control application

64Mb flash file system for infotainment application

GM Embedded Software History

Assembly

Language

1985

Modula-GM

(Ada-like)

1990

ANSI C

1995

Model-based

Development

2000

2005

2010

#include <stdio.h>

file.mat

structBuffer;

vehicle

DEFINITION MODULE

{

VAR nonempty,

nonfull:BOOLEAN; Calibration

13

make[15];

PROCEDURE putchar

(x:INTEGER);

PROCEDURE getlong

(VARmiles;

x:INTEGER);

float operating_costs;

END Buffer.

Calibration

};

13

Variable

Variable

Variable

void

show_vehicle(struct

vehicle *);

IMPLEMENTATION

MODULE

Buffer;

LDAACONST

#ACPRESUR

N=num_lines;

JSR VAR ADCON

Variable

main()

in, out:void

[0..N-1];

STAA n:

ACPRES

[0..N]; {

BRCLR INPUTS,IACREQ,ACPR050

struct vehicle car[] = {“Chevrolet: 100000L, 3456.78,

Cal_File

BRESET

DIAGMW3,M66DET,ACPR050

Ford, 11000L, 5000.00};

PROCEDURE put (x:INTEGER);

BRCLR

INPUTS,INOAC,ACPR060

show_vehicle (car)

BEGIN

ACPR050 BCLR IF

TBIMW,ACPRESHI

n<N THEN}

JMP IMNRO060

buf[n]:=x;

. . . . . .

void show_vehicle(struct vehicle *vehicle_ptr)

{ . . .

Calibration

Classes of Embedded Systems

•

Deeply Embedded

•

•

•

•

•

Moderately Embedded

•

•

•

•

•

Real Time, Possibly Safety Critical

Examples: Electronic Power Steering, Electronic Brake Controls,

Powertrain, Active safety

Development Tools: Simulink/Stateflow

Future SW Architecture: AUTOSAR

Loosely Real Time

Example: Body Control, Instrument Panel, Heating/Cooling

Development Tools: e.g., Rhapsody

Future SW Architecture: AUTOSAR

Lightly Embedded

•

•

•

Non Real Time, but may include data streaming; Security is important

Example: Infotainment Systems

Future SW Architecture: e.g., QNX/Linux, ANDROID, …

Classes of Embedded Systems

•

Closed-Loop Control Systems

• Based upon control system theory (e.g., PID control)

• Examples: Steering systems, braking systems, propulsion

systems

• GM Tools: Simulink/Stateflow

•

State-Based Systems

• Based upon state transition diagrams

• Example: Body control

• GM Tools: Rhapsody

Classes of Embedded Systems

•

Non Safety Critical – no potential to cause harm

• Detect fault, save diagnostic trouble code, possibly alert driver

• Tools: DFMEA, Requirements-Based Testing, …

•

Safety Critical – potential to cause harm; timing

properties are important

• Fail Safe – detect fault, shut down within required fault response

time, warn driver

• Fail Operational – detect fault, continue to operate, possibly in a

degraded mode, warn driver

• Tools: Preliminary Hazard Analysis, Safety Concept, DFMEA, Fault

Tree Analysis, Requirements Analysis, … Safety Case

Model-Based Development

Environment

¶

Algorithms: Simulink / Stateflow, Rhapsody

¶

Plant modeling: Simulink, Saber, GT Power,

AmeSim, CarSim, …

¶

Non Functional System Properties

– Timing / Utilization: SymtaS

¶

Electrical: Design Architect, Siemens NX

¶

DOORS, Gears, Rhapsody, RTC, Synergy

Outline

¶

Introduction

¶

Embedded Systems Development at GM

¶

Product Line Engineering

¶

Additional Topics

General Motors

Electrical, Controls and Software

¶

20

GM has one of the most complex

systems and software product line

engineering challenges in the world

–

3000 contributing engineers

–

300 hierarchical subsystems

–

Thousands of variant features

–

Millions of product instances per year

–

Tens-of-thousands of unique product variants

–

Dramatic increase in variation due to new

propulsion systems and active safety

–

Global diversity in legislative regulations

–

Extreme economic and competitive pressures

–

Product line and feature set evolves annually

–

15 concurrent development streams

System Design Motivation

200

160

140

120

Product Types

Supported

100

Simultaneous Parallel

Releases From Core

80

B u ild T im e s 2 0 0 4 -2 0 0 8 Q 1

60

120

40

20

100

0

99

00

01

02

03

04

05

06

07

08

CY of Engineering

M in u te s

Number of Core Software Parallel Releases

180

09

10

11

12

13

14

80

ECM

TCM

60

L in e a r (E C M )

L in e a r (T C M )

40

20

0

2004- 2004- 2004- 2004- 2005- 2005- 2005- 2005- 2006- 2006- 2006- 2006- 2007- 2007- 2007- 2007- 2008Q1

Q2

Q3

Q4

Q1

Q2

Q3

Q4

Q1

Q2

Q3

Q4

Q1

Q2

Q3

Q4

Q1

Q u a rte rs

21

GM Enables massive Reuse through

Software Product Lines

¶

A Product Line is a set of systems sharing a

common, managed set of features that are

developed from a common set of core assets in a

prescribed way

¶Why Product Line over Products for GM Embedded

Software?

– As much as an 85% reduction in effort for a second

(third, fourth, etc.) application

– As much as a 70% reduction in field claims overall

Macro Engineering

Method

A System of Systems of Systems

Best Fit

Selection

Standardized

Set of

Deployments

Each Deployment Applied

to Multiple Vehicles

23

Development

ACC

LDW

LXC

CTD

KLE

VRP

ACC-v1

ACC-v1

ACC-v1

ACC-v1

ACCv1

IMC-v1

ACC-v1

ACC-v1

LXCv1

ACC-v1

ACC-v1

VRPv1

KLEC-v2

EngC-v1

ACC-v1

ACC-v1

KLEC-v1

ACC-v1

ACC-v1

LXCv3

EngC-v1

ACC-v1

ACC-v1

LDW-v1

DFI

ACC-v1

ACC-v1

CTDv1

ACC-v1

ACC-v1

ACCv1

EngCyc

IMC

ACCv3

VRPv2

DFI-v1

KLEC-v5

LXCv3

EngC-v1

DFI-v5

VRPv1

DFI-v3

CTDv1

Chevrolet

24

Buick

Software Product Line - Single Vehicle View

Vehicle

Controller

Increasing

level of

integration

Assembly

SW Components

Requirements

Decreasing

level of

abstraction

Subsystems – Chassis Engine, etc.

Vehicle

Software Product Line - Single Component View

Controllers 1-n

Assembly

Increasing

level of

integration

SW Component

Decreasing

level of

abstraction

Requirements

Subsystems – Chassis Engine, etc.

Vehicles

Software Product Line - Components X Vehicles

Represents all builds in

the Product Line

Represents all

components in the

Product Line

Represent all vehicles

supported by the

Product Line

Outline

¶

Introduction

¶

Embedded Systems Development at GM

¶

Product Line Engineering

¶

Additional Topics

Additional Topics

•

AUTOSAR

•

Multicore systems

•

Cyber Physical System

•

•

•

Virtual Development

Multi Domain Models

System Optimization

•

Safety-Critical Systems

•

SysML, AADL, East ADL, SystemC

Thank You!