What is Cost Engineering?

advertisement

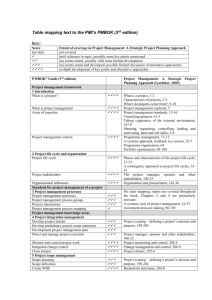

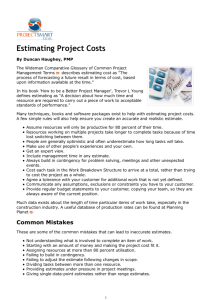

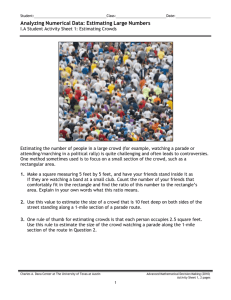

www.costengineering.eu Degree: Mechanical Engineering Experience: Technical Director, Cost Engineering Consultancy B.V. More than 40 years of industrial experience in consulting various industries such as oil & gas, petrochemical, power, mining & minerals, chemicals, construction and pharmaceutical. Professional Field: Co-founder of Cost Engineering Consultancy Member of NAP/DACE, AACEI, ICEC and AcostE Teacher of cost engineering courses Cost Engineering Consultancy: Cost Engineering LinkedIn Group (> 6000 members) Facebook Twitter kdesbouvrie@costengineering.eu www.costengineering.eu What is Cost Engineering? • Cost Estimating • Cost Control • Planning Challenges of the Modern Cost Engineer Achieving an Integrated Work Process through a Holistic Mindset www.costengineering.eu AACEI defines Cost Engineering as: “That area of engineering practice where engineering judgment and experience are utilized in the application of scientific principles and techniques to the problems of cost estimating, cost control and profitability”. www.costengineering.eu The Profession of Cost Engineering: Applying methods and techniques for: Cost Estimating Cost control Planning Contracting / Tendering Quantity survey Risk Assessment Value Engineering www.costengineering.eu www.costengineering.eu Some advise: Keep it simple, Cost Engineering is not “Rocket Science” In science 1 + 1 = 2, in cost engineering 1 + 1 = 3 Keep in mind that cost engineering is a profession! www.costengineering.eu “It costs time” “It costs resources” “ It costs money” Everything invested in assets and projects is a Cost www.costengineering.eu A day in the office Telephone rings….. A business partner !!!! www.costengineering.eu Cost Estimating www.costengineering.eu www.costengineering.eu Past performance is no guarantee for future results www.costengineering.eu “An evaluation of all the costs of the elements of a project or effort as defined by an agreed-upon scope.” (AACE 10S-90) Cost Estimate • Involves assumptions and unknowns • Involves probabilities (and therefore ranges of costs) • Involves a given scope • Contingency covers variability within the defined scope - not changes in scope www.costengineering.eu Identification phase Project initiation note Definition phase Feasibility study Development plan ± 40% Screening estimate ± 25% Study estimate ± 25% Budget estimate Economics Economics Economics Step 1 Step 2 Step 3 Initial commit. plan Approval Approval initial execution plan Basis for design Execution phase Project specification Detailed design ± 10% Control estimate commit. plan Economics Step 4 Materials procurement Construction Commit. & cost control Change control ± 5% Counter estimate Step 5 Project execution plan Operations reference plan Contract control Operational phase Abandon phase Step 6 Step 7 Identical to Execution phase Identical to Execution phase Commission. start-up handover Operations reference plan Close out Abandon project Project debrief Purchase order control Review Review Reporting Approval Approval www.costengineering.eu An estimate should not be regarded as a single point number (or cost) An estimate is a range of potential cost outcomes, and associated probabilities of occurrence Thus – the accuracy range of an estimate is a probabilistic assessment of how far a project’s final actual cost can be expected to vary from the estimate • The range is driven by risks www.costengineering.eu Estimate Level Level of Project definition End Usage Methodology Capacity factored Parametric Models, Judgment or analogy 5 0% to 2% Concept Screening 4 1% to 15% Study or Feasibility 3 10% to 40% 2 1 Expected Accuracy Range Preparation Effort L: -20% to -50% H: +30% to +100% 1 Equipment factored or Parametric Models L: -15% to -30% H: +20% to +50% 2 to 4 Budget, Authorization or Control Semi-detailed unit cost with assembly level line items L: -10% to -20% H: +10% to +30% 3 to 10 30% to 70% Control or Bid / Tender Detailed Unit Cost with Forced Detailed takeoff L: -5% to -15% H: +5% to +20% 4 to 20 50% to 100% Check Estimate or Bid / Tender Detailed Unit Cost with Detailed take-off L: -3% to -10% H: +3% to +15% 5 to 100 www.costengineering.eu 90/10 +40% 90/10 50/50 Base -25% ~2-8% Bas e Bas e 10% +10% 90/10 90/10 ~1-5% 50/50 Base Base Base 10/90 Order of magnitude D Class5 Study Type C Class4 Budget Type B Class3/2 Control Estimate Class1 Zero baseline www.costengineering.eu Influences on the estimate Scope definition Tools Database Risk • Systemic Risk • Project Specific Risk Market influences Knowledge of the cost engineer www.costengineering.eu What happens with too much pressure? www.costengineering.eu “Measurements are the key. If you cannot measure it, you cannot control it. If you cannot control it, you cannot manage it. If you cannot manage it, you cannot improve it.” - James H. Harrington www.costengineering.eu Cost Control www.costengineering.eu www.costengineering.eu There are two processes used for controlling the costs of the project. 1. Change Management – a formal process that identifies any requested (or un-requested) changes to the contract. 2. Forecasting – predictions of the costs at completion for any cost elements in progress or not yet started. www.costengineering.eu Don’t run and hide !!! All changes shall be documented, regardless if no net change in schedule or cost has happened. www.costengineering.eu Forecasts are much like estimates. Whereas an estimate is always for future activities and assets, forecasts are predictions of the costs at completion for cost elements in progress. www.costengineering.eu 1800 Budget plan 1600 1400 BCWS (Budgeted cost of work scheduled) 1200 ACWP (Actual cost of work performed) 1000 800 600 BCWP (Budgeted cost of work performed 400 200 0 1-apr 7-apr 14-apr 21-apr 28-apr 5-m ei Budget 12-m ei Earned 19-m ei 26-m ei 2-jun 9-jun 16-jun 23-jun Actual www.costengineering.eu Challenges of the Modern Cost Engineer www.costengineering.eu Involvement Feedback/Learning/Knowledge Engineering Business Project Director Operations /Commissioning Construction Process Engineering Detailed Engineering /Procurement Estimating Business Planning Feasibility Planning Project Planning Execution Project Control Start-up www.costengineering.eu Involvement Process for Technical Projects Regulation Government Engineering Process Flow Project Lead Permits Money Contractors Process Engineers Risk Assessment Business Case Data sheets Safety Sub Contractors Time / Schedule Discipline Engineers Quality Health Cost Engineers Environment www.costengineering.eu www.costengineering.eu Potential of Decisions to Influence Value Potential of Changes to Destroy Value Project Life Cycle (Better Scope Definition/Time) More involvement results in better scope definition www.costengineering.eu From: Hollmann, John K., Best Owner Practices For Project Control, 2002 AACE Transactions Front End Loading (FEL) Percentage Above or Below Industry Average Cost 20% 15% 10% 5% 0% 5% Lower Cost = 1% Better ROE -5% -10% BEST 3 3,5 4 GOOD 4,5 5 5,5 FAIR 6 6,5 FEL Index POOR 7 7,5 SCREENING 8 8,5 9 www.costengineering.eu Percent That Achieve Objective As Reported by IPA, Inc. www.costengineering.eu Achieving an Integrated Work Process through a Holistic Mindset www.costengineering.eu www.costengineering.eu www.costengineering.eu www.costengineering.eu www.costengineering.eu www.costengineering.eu www.costengineering.eu www.costengineering.eu Mixing all different ideas together www.costengineering.eu A process for collecting, maintaining, and analyzing project historical information so that it is ready for use in an effective form by each functional process Empirical information is the most fundamental project planning resource available It is manifested in the form of quantified and documented historical data and information The purpose is not to repeat history, but to learn from it (continuous improvement) www.costengineering.eu www.costengineering.eu Measurement Methods and Tools Cost Accounting and Resource Tracking Planning Methods and Tools Physical Progress and Performance Measurement Control Baseline Information Measurements Assessment Methods and Tools Performance Assessment Reference Tools Actual Schedule Data Actual Cost Data Forecasting and Change Management Actual Resource Data Project Learnings Assessment Support Information Forecast & Change Information Scope Development Resource Planning Cost Estimating and Budgeting Procurement Planning Schedule Planning and Development Value and Risk Management Reference Tools Project Schedule Estimating Resource Benchmarks/ System Reference Reference Reference Validation Learnings Information Information Information Metrics Project Historical Database Management Asset Historical Database Management (6.3) www.costengineering.eu Suddenly, a heated exchange took place between the King and the project manager What was objective? “dig a ditch next to the castle wall” or “defend the castle from attack” Cost Engineering Consultancy HQ - PO box 25, 3330 AA Zwijndrecht, IJsselmeer 32e, 3332 EX Zwijndrecht T: +31 78 620 09 10 F: +31 78 620 91 42 E-mail: info@costengineering.eu www.costengineering.eu www.costengineering.eu

![“It [Estimating] seems to have been written by estimators, for](http://s3.studylib.net/store/data/008159768_1-3e6e6f7b6ac8f873fb36163141747a6b-300x300.png)