Middle School Entrepreneur—From Idea to Production

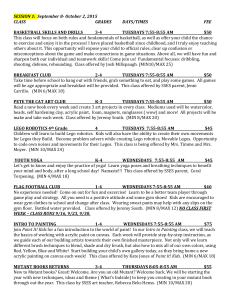

advertisement

Middle School Entrepreneur— From Idea to Production John Muir Middle School Horace Mann Middle School Wausau, Wisconsin History of the Program Where we were How did we get here Business/Technology Collaboration Resources needed Business Course Entrepreneurship Class Length Class Set-up Topics covered Prototypes PowerPoint—Business Plan Junior Achievement—It’s My Business Seamless Transition to Manufacturing Idea to Production Manufacturing Course th 8 Grade Manufacturing (Time Line) Pen Act. Safety Pay logs Intro MFG Anxiety Stress Apathy Jigs/fixtures Machines Quality Measurements Comfort Zone Smooth ride (temporary) Turbulence Week 1 Week 2 Job assignments PM Training Week 3 Week 4 Pre-production run Week 5 Week 6 Fearless comfort (DANGER) Week 7 Week 8 Relief Celebration Independence SUCCESS! Boot Camp Time tracker Lean Manufacturing 7 deadly wastes Kaizen Value vs Nonvalue Intro to manufacturing Safety Production A Typical Day… Punching In First shift begins 7:50 am Workers punch in Start early • Are the workers ready • TIME TRACKER!! Work permit can not work without it! 7:50-7:54 am Wood Floater- getting lumber out to work stations Inventory Control- inventory count, plant layout and product distribution *All this happens during Plant Managers production plan delivery 7:50-7:54 Risk Safety Control- Shift safety worker placement Workers rotate doing safety (Wayne, Ken) • Duties Monitors safety violations 7:54 am Plant “Hands” Manager is the Boss! Empower Plant Manager Delivers Production Plan PM’s produce all PowerPoints • Daily Goals, Job charts, etc. Plant Managers Ensure a Quality Product Monitors QC Rewards Responsibilities Worker of the day Trains QC Work uniform Review Production Plan Punch In - fill in paycheck log Plant Manager Seating Charts Building Processes - QC needs to know all steps in great detail QC Training Production Plan Job Charts - QC placement - Worker placement Worker Motivation Feedback on improvements Flow Process Charts -Need to know every step of the process -No bottle necks -No idle time Monitoring Quality 7:55-8:33 Inventory ControlTrack product routing process with Bingo Charts Prevent overproduction Forecast/predict production deadlines Inventory Control Keeps product organized in storage - no bottle necks - no standstills Checks off completed Processes - use bingo chart Responsibility's Work uniform Punch In - fill in paycheck log Carries out job task set out by PM Training Process during lunch -communicate with PM Feedback on improvements - what should we make more of Lets PM know when enough pieces are produced - stop before we overproduce the amount we need 7:55-8:33 Wood Floater- Product transportation Picked up and delivered from and to IC to QC BIG JOB! Wood Floater Get product to correct job station on time - be fast and efficient at this job Never sit still always looks for product to transport Feedback on improvements Responsibility's Work uniform Training Process during lunch - work closely with IC Carries out job task set out by IC Punch In - fill in paycheck log Have product ready before class starts - product should be at correct work stations - punch in when get to class - always check in with IC Router #1 Disc Sander Router #1 Band saw 1 Band saw 1 Band saw 1 Band saw 1 CNC Router #1 Router #1 Router #1 Router #1 Drill press 1 Router #1 Band saw 1 Drill press 1 TABLE 7 TABLE 6 TABLE 5 Band saw 1 Drill press 1 TABLE 1 TABLE 2 TABLE 3 TABLE 4 Starting Point Flow W W Flow QC QC W QC PM WF QC QC QC W Finishing Point W Flow W Plant Process Flow Accountant Hour OS Drill Press Disc Sanders Router Router Router Router Band Saw QC Band Saw CNC Band Saw WF Band Saw Safety Line Safety Line Band Saw Safety Line Safety Line Safety Line Work Stations Safety Line 7:55-8:33 Quality Control: Help carry out production Train workers Check product quality Quality Control Worker Motivation Monitoring Quality Work uniform Responsibility's Carries out job task set out by PM Training Process during lunch Feedback on improvements - no bottle necks - no standstills Punch In - fill in paycheck log 7:55-8:33 Account Managers- Collect paycheck logs/time cards, payroll, handout paycheck, track worker progress DAILY GRADE!!! Time Cards Accounting Payroll Pay Logs Account Manager Bonuses Sick Days Payroll Training Accountability Incentive tracking Deductions Employee reports (communicate with Plant manager) Payroll Procedures Punch In - fill in paycheck log Account Managers Monday Handout new time cards Handout new pay log Print collection sheet Collect time card and pay log from last week Tuesday/Wednesday Collect forgotten time cards and pay logs Enter account information into spread sheet Thursday Print paychecks Friday Handout paychecks Your Pay •Workers •$15/hour •$600/week •$2400/month •Quality Control •$22/hour •$880/week •$3,520/month •$28,000/year •$42,240/year •Plant Manager •$45/hour •$1,800/week •$7,200/month •$86,400/year 7:55-8:33 am Waste Management- Recycle waste Sort “cut offs” and reclaim usable wood Communicate with Inventory Control and Plant manager-Making sure they use recycled waste FIRST. 7:55-8:33 am Production Workers Worker Actively listen to QC Follow instructions Punch In Be able to measure Responsibility's Work efficiently with quality - no bottle necks - no standstills Be to work on time Be Motivated - use red, blue, yellow cups Feedback on improvements - how can we do this better Punch In - fill in paycheck log 7:55-8:33 am Clean-up Czar- Delegates the clean-up process Blows the work whistle “Cleeeeaaannuuppp!!” Chain Of Command PLANT MANAGER QC QC QC QC Workers Workers Workers Workers ACCOUNT MNGR RISK CONTROL (Safety) INVENTORY CONTROL WASTE MNGMT WOOD FLOATER LUNCH! Plant Manager Training Collaboration Lunch Time: PM support group Between Schools Outsourcing/Globalization PROBLEM SOLVING Material lists Math: • Layout (math teacher teaches) • Measurement • Engineering • Jigs and fixtures • Design problems • Production troubles: (video) • Bottlenecks, standstills, etc. Industry Partnership Mark DuginskiDonated machines Jig/fixtures (fences,etc) Accuracy/precision Interchangeable parts-Eli W., Henry F. TEAM STUDY Over-time Production STRIKE! Summary Student Driven!!!! Would you let your students drive your car with you in the back seat? Failure leads to success Not about the product it’s the PROCESS Not to make factory workers Life Skills- communication, team work, organization, people management, leadership/follower-ship, conflict resolution Business+Technology=Student Success!