35 Work Zones

advertisement

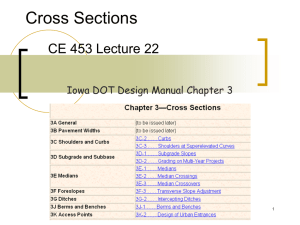

Work Zone Traffic Control CE 453 Lecture 35 1 Objectives Describe a maintenance of traffic plan for a roadway project Define work zone problems and reasons for same Identify work zone traffic control devices Present details of work zone traffic control 2 Key resources … http://mutcd.fhwa.dot.gov/ - contains standards and principles for design, installation, and maintenance of traffic control devices in work zones http://wzsafety.tamu.edu/ AASHTO Roadside Design Guide: Chapter 9 discusses: Traffic Barriers, Traffic Control Devices and Other Features in Work Zones. Should be used with Traffic Control Devices Handbook – Part VI 3 http://safety.fhwa.dot.gov/fourthlevel/pdf/bestprac.pdf Maintenance of Traffic Plans How/when traffic is maintained during construction Typically required/not always – really needed Include the following (if needed): Diversion/detour alignments Tapers and lane drops (see MUTCD) Pedestrian accommodations Traffic control (signals, sign type, sign location) 4 http://www.fhwa.dot.gov/tfhrc/safety/pubs/89035/89035.pdf Maintenance of Traffic Plans Pavement marking, cones, barriers for channelization Illumination and warning lights (steady for path, flashing for single points) Policies for removal of signs, etc. Staging of Traffic (how it flows) Need for flaggers, etc. Notes (e.g, move or sign all equipment when not in operation in the work zone) No parking of employee cars in work zone 5 Maintenance of Traffic Plans Cost estimate must include labor, signs, cones, etc. Often not given proper time or attention – switching time most dangerous 6 Why are Work Zones more Prone to Crashes? Why are work zones difficult for drivers and subsequently dangerous for workers? Violate – Expectancy Increased – Workload Combine – Both 7 Work Zone Safety Facts Late 90s … ~700 deaths/year … now, ~1000! Tractor/trailer involvement in work zones crashes are high (26% of fatalities) Work Zone crashes generally more severe (more injuries/fatalities than national average)Fixed object impacts result in more injuries/fatalities than vehicle to vehicle impacts ½ of work zone fixed object impacts occur at night (impact on staging??) 8 Work Zone Safety Facts 1994-98 Average was that 16% of work zone fatalities were peds/bicyclists Fatal work zone crashes are twice as high as non-work zone fatals on urban interstates (14% are FATAL!) The majority of fatal work zone crashes occur on 55 mph or greater speed limits (No need for slow speed MOT? Ped/bike/ car fatalities? – increase over 35 mph but occur much lower) 29% of fatals on weekends! (most in summer and fall) ~150 workers killed each year (who are the workers???) Utility work in bike lanes can often be accomplished without blocking the entire lane. 9 http://safety.fhwa.dot.gov/ped_bike/univcourse/swless12.htm Number of Work Zone Fatalities - 2002 10 http://www.dot.state.ia.us/workzone/index.htm 11 12 Work Zone Traffic Control Devices Cones/Tubular Markers Vertical Panels Drums (watch breakaway lamps – ballast at bottom and no greater than 25 kg) Barricades Type I, II, and III Shadow Trucks, etc. for moving construction or maintenance 13 Work Zone Traffic Control Devices Temporary barriers (Portable Concrete Barrier (PCB) used by many states - uses: bridge widening, shielding roadside structures, roadway widening, and the separation of two-way traffic on a normally divided roadway) Glare Screens (block view of construction, for design consider separation distance, vertical curvature, horizontal curvature) Signs and Supports – meet normal specifications – breakaway within clear zone, etc. (MUTCD) Warning lights (minimum height 3 ft. or 900 mm – securely fasten and battery on ground – why?) 14 Detour considerations Speed Capacity Distance Safety 15 How to increase detour capacity (e.g., during I-235 reconstructions – Univ. Ave., etc.) eliminate some turns reroute some trucks and buses ban parking ban loading/unloading during peak eliminate some bus stops coordinate signals widen the traffic way implement one-way ITS??? (incident management, esp.) 16 http://www.dot.state.ia.us/design/e00_toc.htm#Chapter_9 17 18 Specifics for Work Zones Fundamental principles of work zone traffic control design Four work zone areas and their components Taper lengths and types Advance signing applications and factors that impact setup 19 Work Zone Traffic Control Design – 10 Fundamental Principles (MUTCD Part 6) Why? worker/motor vehicle safety in temporary traffic control areas Traffic safety must be integral and high-priority during project development (from planning to construction) and rehab/ maintenance or utility activities Follow same principles of normal permanent roadside/roadway designs (goal is use comparable geometrics/traffic control if possible) 20 Fundamental Principles (cont.) Produce a traffic control plan (TCP) (understand before field work) Traffic should be inhibited as little as practicable Avoid frequent and abrupt geometry changes Provide for incident management vehicles Minimize work time and do off-peak if possible Guide drivers/peds in a clear and positive manner approaching and through zone (adequate traffic control, proper action with permanent control, flagging) 21 Fundamental Principles (cont.) Routinely inspect your traffic control elements Maintain the roadside during construction (for safety) Train all levels of workers in temporary traffic control zone safety Provide statutes that allow work zone traffic control (no real engineer control???) Maintain good public relations (media) 22 Activity Area Storage (not shown) Work Buffer Traffic 4. Termination Area – returns traffic to normal 3. Activity Area – where the work happens 2. Transition Area – channels the traffic 1. Advance Warning - what to expect 23 Older AASHTO New MUTCD 24 Tapers – Important Safety Element of Work Zones (Why?) Used in transition and possibly termination areas of work zone Use a series of channelizing devices and/or pavement markings Observe after implementation (adjust as appropriate) Channelizing device spacing (in feet) approximately equal to the roadway speed in MPH 25 Taper Lengths (See Table next page) 40 mph or less L = WS2/60 45 mph or greater L = WS L = taper length in feet W = width of offset in feet S = Posted speed, off-peak 85th percentile speed before work, or anticipated operating speed in MPH 26 27 Taper Types Merging – longest because it requires drivers to merge with other traffic (use L minimum) Shifting – merging not required, but a lateral shift is (use ½ L minimum) Shoulder – used where shoulder may be mistaken for driving lane (use 1/3 minimum, but L is traveled on) Downstream – provide visual cue that original lane is now accessible (optional – if used 100 feet/lane minimum, 20-foot device spacing) One-lane, Two-way – used when one lane closed and used by both directions (use 100-foot maximum and typ. flagger) 28 29 Warning Signing for Typical Applications Place warning signs in advance of work areas at spacing indicated Distances measured from transition or point of restriction start Table 6C-1 suggests spacing for warning signs on different roadway types • “A” is distance from transition/point of restriction to first sign • “B” is distance to from first to second sign, and • “C” is distance from second sign to initial sign encountered by driver (in a three-sign series) 30 31 Selecting a Typical Sign Setup Consider: Duration of Work (long-term stationary, intermediate-term stationary, short-term stationary, short duration, and mobile) Location of Work (e.g., outside shoulder, near/on shoulder, median, on roadway) Roadway Type (e.g., rural two-lane, urban arterials, other urban arterials, rural or urban divided/undivided, intersections, and freeways) • MUTCD has 44 typical applications split by these categories 32 33 34 35 36 37 I65 Work Zone, North of Louisville 38 39 40