Dust Explosion(21-25) - UCSB College of Engineering

advertisement

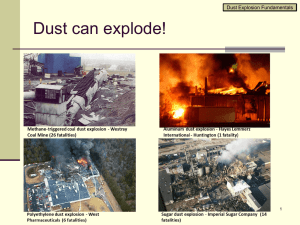

Dust Explosion - Mallika Gharpure Ravikumar gogar Trupti Gawai Gokul Gopal Samyak Gayakwad Introduction What it is? Dispersion of powders in air Form of cloud Suitable concentration Presence of effective ignition source Where it can occur? Combustible powders Fine materials Foods, pharmaceuticals wood, plastics Metals, rubber How it can occur? Explosible Dust Particle size distribution for propagation of flame Presence of oxidant in atmosphere Dust cloud concentration within explosion range Ignition source What are the associated factors? Dust and explosion violence : pressure, speed Composition of Dust Particle Size Concentration of dispersed dust : LEL,UEL T, P, moisture content, scale of vessel Case Study Process : equipment used to pulverize aluminumalloy air recycled through a grinder, cyclone product separator, blower a side stream to extract undesired dust to a dust collector Batch To Continuous a much higher rate of dust generation high concentrations of very fine dust in the recycle stream accumulation of heat in the recycle stream. installer of the recycle system with no experience with combustible powders no explosion prevention or protection devices or systems provided. The Accident concentration of dust in the circulating air stream above LEL in most of the recycle system relatively high temperature of the circulating air exothermic oxidation of accumulated combustible dust in the return-air ductwork an access door on the grinder forcibly ejected, the door struck the LPG cylinder on a nearby forklift truck. Escaping LPG vapors – ignited by the dust fireball from the open grinder door – resulted in a flash fire fatal burn injuries to the forklift driver lessons learned from this incident (1) (2) (3) (4) Every significant change in a process should be subjected to a Management of Change analysis Producers of hazardous materials (and particularly small-company producers) need to follow Codes and Standards that apply to their processes Code-enforcing authorities should become more familiar with Codes and Standards that apply to dust-explosion hazards Dust-explosion characteristics need to be included in Material Safety Data Sheets. Dust Control Use dust collection systems and filters Utilize surfaces that minimize dust accumulation and facilitate cleaning Provide access to all hidden areas to permit inspection Inspect for dust residues in open and hidden areas, at regular intervals Use cleaning methods that do not generate dust clouds, if ignition sources are present Locate relief valves away from dust hazard areas Develop and implement a hazardous dust inspection, testing, housekeeping, and control program (preferably in writing with established frequency and methods). Ignition Control Use appropriate electrical equipment and wiring methods Control smoking, open flames, and sparks Control mechanical sparks and friction Use separator devices to remove foreign materials capable of igniting combustibles from process materials Separate heated surfaces from dusts Separate heating systems from dusts Proper use and type of industrial trucks Adequately maintain all the above equipment. Damage Control Separation of the hazard (isolate with distance) Segregation of the hazard (isolate with a barrier) Deflagration venting of a building, room, or area Pressure relief venting for equipment Provision of spark/ember detection and extinguishing systems Explosion protection systems Sprinkler systems References ‘Dust Explosion Prevention and Protection’ By John Barton Process safety progress 2007, vol. 26, no4, pp. 324-329 NFPA 654, Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids Occupational Safety and Health Administration (OSHA), the Massachusetts Office of the State Fire Marshall, and the Springfield Arson and Bomb Squad. "Joint Foundry Explosion Investigation Team Report." OSHA, Springfield Thank You….