Lifting Procedures - Safety Awakenings

advertisement

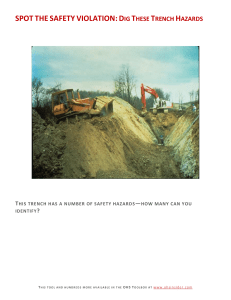

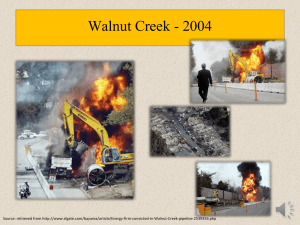

Excavation Safety Objectives: Highlight the hazards of working in a excavation. How to protect employees from cave-ins. Factors that pose a hazard to employees working in excavations. The role of a competent person at an excavation site. Introduction: Cave-ins are perhaps the most feared trenching hazard. But other potentially fatal hazards exist including: Asphyxiation due to lack of oxygen in a confined space Inhalation of toxic fumes, drowning, etc. Electrocution or explosions can occur when workers contact underground utilities. Definitions: Cave-In: Means the separation of a mass of soil or rock material from the side of an excavation, or the loss of soil from under a trench shield or support system, and its sudden movement into the excavation, either by falling or sliding, in sufficient quantity so that it could entrap, bury, or otherwise injure or immobilize a person. Definitions: Excavation Falling onto the Personnel: A RELATIVELY SMALL COLLAPSE MIGHT INVOLVE A CUBIC METRE OF SOIL, BUT A CUBIC METRE OF SOIL WEIGHS OVER A TONNE. PERSONNEL BURIED AT THE BOTTOM OF THE TRENCH UNDER THIS VOLUME OF MATERIAL WOULD BE UNABLE TO BREATHE DUE TO THE PRESSURE ON THEIR CHESTS, AND SO WOULD QUICKLY SUFFOCATE AND DIE. Anatomy of a Cave - In: There is usually no warning before a cave-in Definitions Continued: Excavation – a man-made cut, cavity, trench, or depression formed by earth removal. Trench – a narrow excavation. The depth is greater than the width, but not wider than 15 feet. Shield - a structure able to withstand a cave-in and protect employees Shoring - a structure that supports the sides of an excavation and protects against cave-ins Sloping - a technique that employs a specific angle of incline on the sides of the excavation. The angle varies based on assessment of impacting site factors. Excavation Hazards: Surface encumbrances Utilities Access/Egress Vehicle traffic Falling loads Mobile equipment Hazardous atmospheres Water accumulation Adjacent structures Loose rock or soil Falls Cave-in General Requirements: Before any excavation actually begins, the employer must determine the estimated location of utility installations: Sewer, telephone, fuel, electric, water lines, or any other under ground installations that may be encountered during digging. A competent person will inspect, on a daily basis, excavations and adjacent areas for possible cave-ins, failure of protective systems and equipment, hazardous atmospheres, or other hazardous conditions. Takes prompt corrective measures to eliminate hazards. Adequate protective systems will be utilized to protect employees. This can be accomplished through: Sloping, Shoring, or Shielding. Workers must be supplied with and wear any PPE deemed necessary to assure their protection. Mechanical excavators and power tools should not be used within 0.5 m If a trench is 4 feet or deeper, stairways, ramps, or ladders will be used. The employees must not have to travel any more than 25 feet to reach the stairways, ramps, or ladders. 4 feet and more trenches – Toxic and hazardous atmosphere will be tested daily. Access: The ladder should extend 3 feet above the excavation Access: These two ladders which are lashed together are not an adequate means of egress The ladder should extend 3 rungs above the top of the excavation Ladder to be 1 Meter Above Wall: Excavation Protection Systems: There are three basic protective systems used in excavations and trenches: 1. Sloping and Benching Systems 2. Shoring Systems 3. Shielding Systems Simple Sloping: Benching: Shoring Systems: Support system for trench faces used to prevent movement of soil, underground utilities, foundations. There are two basic types of shoring, timber and aluminum hydraulic. Shoring Systems: Timber Shoring Installations: Hydraulic Shoring: Pneumatic Shoring: Shielding Systems: A- Trench Boxes: The space between the outside of the trench box and the face of the trench should be small as possible, and backfilled to prevent lateral movement of the box. Excavation Inspections: Daily Inspections of ALL excavations by Competent Person at Start of shift, or as needed, following rainstorms or other hazard-increasing event: Possible cave-ins Protective system failure Water accumulation Hazardous atmospheres Competent person has authority to remove workers from Causes of Cave – Ins: Causes of Cave – Ins: When water is present in an excavation it is extremely hazardous to enter. Also no head protection Causes of Cave – Ins: Note: telephone pole adjacent to excavation, not supported / removed Inadequate Protective System: This excavation has inadequate support posts and egress access. Inadequate Protective System: This worker is in a trench with no protective system, that is not sloped or benched and has no means of egress. Hazardous Condition: The weight and vibrations of the machinery above make this a very hazardous condition. They should not be working under any machinery. Hydraulic Trench Support: Using hydraulic jacks the operator can easily drop the system into the hole. Once in place, hydraulic pressure is increased to keep the forms in place. Trench pins are installed in case of hydraulic failure. Hazardous Atmosphere: Test excavations more than 4 feet before an employee enters the excavation for: Oxygen deficiency. High combustible gas concentration. High levels of other hazardous substances. Means of Egress: A stairway, ladder, or ramp must be present in excavations that are 4 or more feet deep, and within 25 feet of the employees. The ladder should extend 3 feet above the excavation Summary: The greatest risk in an excavation is a cave-in. Employees can be protected through sloping, shielding, and shoring the excavation. A competent person is responsible to inspect the excavation. Other excavation hazards include water accumulation, oxygen deficiency, toxic fumes, falls, and mobile equipment. REMEMBER: