2013-Presentation-Sathish - Performance Excellence Network

advertisement

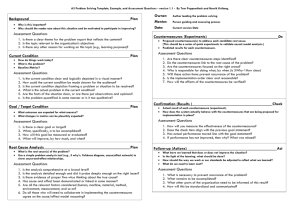

Tools to Achieve Performance Excellence Presenter Biography- Sathish Selvaraju Lean, Lean Six Sigma and Business Transformation 5+ years experience in applied process improvement methodologies M.S. in Industrial and Systems Engineering Research interests: – Organizational culture transformation – Lean and Six Sigma methodology – Leadership and Change Management – Supply chain management 1 Patent, 2 publications and invited industry talks Member of IIE, SEMS and PEN Office – Rochester, MN, Lives – Rochester, MN Personal – Married with 1 kid (1 YR) Email: selvaraj@us.ibm.com Lean–8 Step Problem Solving Methodology Learning Objective • At the end of this module, the participants will be able to: • Describe the 8-Step Structured Problem Solving methodology • Define an effective Problem and Goal Statement • Integrate quality and process improvement techniques into the 8-step problem solving structure • Explain how the 8-Step methodology allows for Corrective and Preventive Actions During Problem Solving • Discuss the benefits of Root Cause Analysis • Describe techniques for Measuring and Sustaining your process improvements • Discuss how to apply the 8-Step Methodology on a business challenge or process improvement project Benefits of Problem Solving • • • • • • Eliminate time lost in debate Identify weak points in the processes Discover systematic causes Explain why an incident occurred Gives factual representation of the incident Compare what actually happened against what should have happened The 8-Step Structured Problem Solving process is based on the Plan-Do-Check-Act process When to Use Plan–Do–Check–Act As a model for continuous improvement Plan Act / Adjust When starting a new improvement project Do Check When developing a new or improved design of a process, product or service When defining a repetitive work process When planning data collection and analysis in order to verify and prioritize problems or root causes When implementing any change or transformation effort Reference: W. Edwards Deming’s Continuous Improvement Cycle (“The Deming Cycle”) The number one reason why projects fail is ineffective and insufficient planning… 1. Ineffective and insufficient planning 2. Lack of customer focus and participation 3. Lack of Senior Management support 4. Badly defined requirements or objectives 5. Ineffective change control process 6. Lack of necessary resources 7. Poor monitoring and evaluation 8. Little or no risk analysis 9. Poorly trained project manager 10.Ineffective communications planning Source: Gallup Management Institute 8-Step Structured Problem Solving Process aligns to the PDCA process. 1. Describe the problem a) b) c) d) Plan Do Check Act 2. 3. 4. 5. 6. 7. 8. Identify the team Define problem statement Understand the process (and point of cause) Define Goal statement Implement containment actions Perform Cause/Effect analysis; select root causes to fix Develop & select countermeasures Implement countermeasures Measure results (Evaluate) Plan Steps 1, 2, 3, 4 Standardize the Process Recognize the team Act / Adjust Steps 7, 8 Do Step 5 Check Step 6 Source: Gallup Management Institute 1. Understanding the Process A3 Report a. Team and Sponsor: 4, 5. Countermeasures, Project Plan Countermeasure Who When Benefits b. Problem Statement: c. Understanding the Process: <Enter key findings from VOC, VSM, SIPOC, Process Map> 6. Measure Success Internal Process Excellence Financial Excellence Customer Satisfaction People/Employee Empowerment d. Goal Statement: 2. Containment Actions 7. Standardize Process 3. Root Cause Analysis 8. Celebrate Success Step 1: Define the problem has four sub-steps with Step 1a being Form the team Plan Act Do Check Teams • Are limited in size, typically 4 to 8 people • Identify a sponsor for the team • Contains members from the areas where the problem or improvement opportunity exists • Should have 80% of responsibility and authority to implement the required change There are several key roles on an 8-Step team Sponsor Defines ‘high level’ team Links team mission to organizational objectives Addresses cross-organizational issues Sets expectations for project status readouts & updates Facilitator Provides guidance through the problem solving process Guides the team discussions; stays objective and neutral Ensures everyone participates Requests reviews with Leader/Sponsor for effectiveness Adjusts direction when necessary Coaches & teaches sponsor, leader and members in the 8-Step process Team Leader Creates an environment of trust, open communication and creative thinking Provides the team with a vision of the project objectives Coaches & helps develop team members; help resolve dysfunctional behavior Maintains all pertinent data Intervenes when necessary to aid the group in resolving issues Communicates progress to Management, Status Meetings Plans team recognition/rewards Scribe Captures meeting minutes Sends progress report as agreed; highlights any open actions Team member Provides ideas, discussion, data, direct observation Have decision-making power Coach Problem solving process Subject Matter Expert (SME) Provides guidance on the 8 Step process Checks in with Team, Facilitator, Leader After the team is formed, the project team begins Step 1b: Defining the Problem Plan Act Do Check A problem is an observable, measureable deviation from a known standard • In business, a problem is a difference between the actual conditions of our current state and those conditions that are required or desired. • Problem statement needs relevant information to be effective! • Current state, Target state and Business Impact • It has to be clear, concise and complete An effective problem statement is key to solving the problem An effective problem statement states both the current and the desired situation. An effective problem statement implies or states explicitly both: The current situation The desired situation The impact statement Simple Example: Our order entry cycle time is 4 days per order, 1 day per order longer than is acceptable resulting in a 10% loss of market share Current situation • Cycle time = 4 days/order Desired situation • Cycle time = 3 days/order Impact Statement • 10% loss of market share Quick Quiz??? Listed below are several examples of problem statements, some of which are effective and some are ineffective. 1. Loan application approval cycle time is taking 3 weeks, which is above the acceptable rate of 2 weeks and is resulting in a 15% applicant defection rate. 2. Clerks take ten days to check billing errors. 3. Our IT systems do not provide the required functions we need!!! 4. In October of 2012, we had 25 customer complaints compared to our standard of 10 per month and is causing a $10M drop in new orders After the problem is defined, the project team begins Step 1c: Understand the process and identify the ‘point of cause’ Plan Act Do Check 1. Draw a process map to create a picture of the flow of information – Capture what’s happening in the process – Look for waste 2. Search for the “Point of Cause” (POC) – the area where the problem originates – Ask 5 W’s and 1 H : Why, What, Where, When, Who, How much – POC validates problem and narrows the scope The 5Ws and 1H questions are Why?, What?, Who?, Where?, When?, and How often? • To understand the process and drive to points of cause ask why, what, who, where, when, and how often. • Ask Why… – – – – • Ask When… – – – – • Why this problem? Why might it happen? Why did it occur? Why… When was it found? When did it happen? When might it happen again? When… Ask What… – – – – – What product? What equipment? What size? What is it made of? What… Ask Where… – – – – Where did it come from? Where did we find it? Where might we find more? Where… Ask Who… – – – – Who found it? Who made it? When checked it? Who… Ask How… – – – – – How many? How often? How big How far? How… TQM Tools for Identifying the Point of Cause Control Chart Pareto Chart Process Map Ishikawa Diagram Trend Chart Check Sheet Scatter Plot After the process is understood, the project team begins Step 1d: Develop goal statements Plan Act Do Check Goals should be SMART S – Specific M – Measurable A – Achievable R – Relevant T – Time-based Here are guidelines for creating a goal statement • Goal statements are written in the format <action verb> + <object> • Do not use verbs that represent relative progress, for example, improve or Increase, since we cannot measure these relative improvements • Do not use imprecise words, such as leverage, enable, partner, optimize, or focus on. An actual quote: "My goal is to ensure our employees are enabled to leverage IBM's investment in our IT environment by providing information on the latest software, tools, and techniques.“ • Goal statements should not be checkpoints, for example, “Check with...” or “Make sure that....” or “Investigate…” • Goal statements are new, high-impact targets to move the business forward, not business as usual, for example, “Continue to ....” Example: Communicate to employees in a Direct, Open and Sensitive (DOS) manner to create a culture of mutual respect and trust. Here are guidelines for defining the success measures for a goal Success Measures • Are the critical few things that tell us we are making progress in achieving our goal • Are unique, observable, measurable, direct proof that our actions are producing tangible, sustainable results • Show the desired trend or direction – Increase in …by % or number – Decrease in …by % or number • Are not simply the implementation of the goal • Define a balanced view of success using the Balanced Scorecard components – – – – People - Learning and Growth Internal Business Processes Customer Value Financial (ROI) In the Balanced Scorecard, all the components are equally important… Lagging Indicators Financial Customer Value Internal Business Processes People – Learning and Growth Leading Indicators Process and People measures are great ‘predictors’ of Financial and Customer Value measures Let’s consider an example of a goal statement with success measures Problem Statement: The Zoom Car Company is not meeting its daily quota of producing 100 of their popular Easy Drive cars per day causing a drop in Sales and Profits. Goal Statement: Produce 100 quality-built cars that meet or exceed customer requirements and that create a net profit of 18% per car by the end of the year. Success Measures: • People: All employees are cross-trained in at least two manufacturing operations • Internal Processes: Defective cars produced per day = zero • Customer Value: The Easy Drive car is voted Car of the Year by Motor Trend Magazine • Financial: 18% net profit per car Quick Quiz??? The elements of the balanced scorecard are: A) Customer Value, Financial Excellence, Process Excellence and Employee Growth B) Quality Metrics, Process Mapping and TAKT Time C) Histogram, Scatter Plot, Correlation Analysis and Check Sheet D) Plan, Check, Act, Do After defining goal statements and success measures, the project team moves to Step 2: Implement containment actions Plan Act Check What are containment actions? • A short-term / temporary corrective action • Some problems must be confined until the root cause has been identified Examples of containment : • Stop production, Add inspection • Install a concrete containment cap over a ruptured deep sea oil well. • Apply a tourniquet on a bleeding arm Do Let’s discuss the criteria for selecting containment actions Business Impact: The extent to which this action helps contain the problem. Easy to Implement: Making the change does not require a great deal of coordination and planning; Making the change does not require a great deal of time and does not require a large investment of capital, of human resource or of equipment or technology. It is within the teams control Reversible: The action, when implemented, may not achieve the results expected. It’s better if the team is able to change things back to the original way of doing things if the containment doesn’t pan out. In your Team, rate each of the above criteria using the following rating scale: High= 9, Medium = 3 and Low = 1, then multiply the 3 criteria to get a product for each potential containment actions. Select those actions with the highest ratings AND rate HIGH in Reversibility Quick Quiz??? Which of the following is an important attribute of a Containment Action? A) It is fun B) It is reversible C) It can takes a long time to implement them D) It is supported by a majority vote After implementing containment actions, the project team begins Step 3: Root Cause Analysis Plan Act Do Check What is Cause and Effect Analysis? A method to identify all possible causes of a problem What is the 5-Why Method? A technique of asking ‘Why?’ 5 times (approx.) to get beyond symptoms to identify actionable root causes 8 Step Formal Structured Problem Solving Observations Problem Root Cause Countermeasures Observable Observations (Symptoms) 1. Water on the living room floor 2. Water on living room ceiling 3. Water on bath room floor 4. Water overflowing from bath room sink 5. Daughter’s hair in sink Problem or Point of Cause 5. Daughter’s hair in sink Analysis Root cause(s) 6. Daughter combs hair over sink 7. Daughter cannot see herself in her room when she combs her hair Countermeasures (Brainstorm actions) Install a mirror in daughter’s room Use the mirror in the hallway Don’t use a mirror – just guess! Other actions ...? Root Cause Analysis and the ‘Fishbone’ Diagram When creating a cause and effect diagram using causal categories, each bone represents one of the 6Ms. . . Measurements Mankind (People) Machine (Technology) Problem Statement or Point of Cause Mother Nature (Environment) Materials Method (Processes) All arrows point towards the problem statement. The Five Whys technique is useful for identifying root causes for each top problem A simple, effective tool for getting to the root causes of problems is the Five Whys technique. For each top problem: 1. Ask “Why is this a problem?” 2. Keep asking "Why?" until you identify a root cause that you cannot change or influence -then stop. Problem Cause Cause Root Cause Can’t Change or Influence? Activity: Conduct a 5-Why Analysis for the “Poor Training” • Effect: The number of shipping errors was 50% more than target. – WHY? • The employees have poor training – WHY? • There is excessive turnover in the employee population – WHY? • Employees are disgruntled – WHY? • They don’t like the new policy – WHY? • Their input was not solicited when setting the policy After completing cause and effect analysis and selecting root causes, the team begins Step 4 : Develop and select countermeasures Plan Act Do Check Countermeasures are actions that need to be taken to overcome the identified problem to reach the defined goal. Here are guidelines for stating effective countermeasures Countermeasures: • Are stated as Do’s and not Don’ts • Are in the format <action verb> plus <object> • Avoid verbs that represent relative progress; for example, Improve or Increase • Do not use soft, fluffy words … Leverage, Enable, Ensure, Partner, Review, Optimize, Support, Focus on, Drive • Answers the question: “What must we do to overcome the root causes and make significant progress in achieving our goal? The ‘Do’s’ and ‘Don’ts’ of Effective Brainstorming In Step 5, the project team implements countermeasures and identifies success measures for each countermeasure Plan Act Do Check • For each selected countermeasure, identify success measure(s) • The success measure(s) should align to the overall success measure(s) of the Goal Statement (step 1d) • Success measures: The unique, observable, measurable, direct proof that our actions are producing sustainable results In Step 6, the project owner measures and reports results of implementing the countermeasure Plan Act Do Check What do I record for results? • Compare results against the initial condition and the goal statement • Confirm effectiveness of countermeasures with data Use Balanced Scorecard components for reporting • Financial (ROI) • Customer Value / Satisfaction • Internal Business Processes • People: Learning and Growth Verification: • Can we now go back and eliminate any containment activities that were put in place (Step 2) ? Measuring success can also be demonstrated through the Quality Management Tools • • Trend Charts Befor e After Target Bar Charts Goal /Standard Before After Histogram In Step 7, the project team standardizes the successful new process Plan Act Do Check Create a plan for Sustaining How do I standardize? Create a Control Plan to make the new way ‘the’ way to do the task. Train all parties involved or affected by the new system. Document the new process (SOP, DOM, Desk Procedure, etc.) Measure, track and report results. Institutionalize – Does this countermeasure apply in other areas? In Step 8, the project team is recognized for its accomplishments Plan Act Do Check Recognize and Share Achievement “The more you do the 8th step, the more they do the 8 Steps” Gracias Hebrew Russian Spanish Grazie Italian Traditional Chinese Arabic Thank You Simplified Chinese Obrigado Portuguese Merci French Danke German English Japanese Korean Thai