Project Management Review Presentation

advertisement

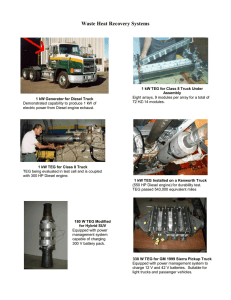

P10462: Thermoelectric Power System for Cookstove Young Jo Fontaine – ME – Thermoelectric Design, Placement, and Thermal Analysis Dan Higgins – EE – Power Control System Shawn Hoskins – ME – Project Leader, Interface Liaison Luke Poandl – EE – Battery and Auxiliary Power Dan Scannell – ME – Fan Design/Selection, Placement, and Flow Analysis Rural Haitians currently cook indoors using inefficient wood-burning stoves Due to incomplete combustion, particulate emissions are released and fuel is not being used to its full potential The people of Haiti face serious health problems due to smoke inhalation as well as complete deforestation of their country due to inefficient use of wood Goal of project track is to develop a stove that uses a thermoelectrically powered fan to introduce proper airflow and promote complete combustion of fuel Goal of project is to develop a thermoelectric power system for a COTS cookstove Thermoelectrics create an electric potential when subjected to a temperature difference Using the heat from the fire, a thermoelectric module could possibly produce power for the fan, recharging a battery, and auxiliary uses (i.e. cell phone charging) Power a fan using TEG Start fan on battery power When a sufficient temperature difference across the TEG is realized, power fan with output of TEG Recharge the batteries with TEG power output Provide auxiliary power for charging a cellphone with TEG power output System should be affordable for Haitians and simple to build Current stove has fan that runs off AA batteries Objective is to provide similar airflow using TEG as power source System is designed as a “backpack” unit ◦ Can be affixed to multiple stoves ◦ Requires only two openings to be cut in current stove’s wall Heat is supplied to the TEG through an aluminum rod (exposed to fire) and flat plate TEG is cooled by an aluminum heat sink and airflow from the fan Airflow is directed through a duct similar to the heat sink geometry and into the stove System starts on battery power (3 AA’s) System switches to TEG as main power when TEG begins to provide sufficient power TEG powers the fan, recharges the batteries, and provides power for charging a cell phone System was designed for Taihuaxing TEP112635-3.4 ◦ ◦ ◦ ◦ ◦ Provides 2.8 Watts of power at peak operation Single order: $50 1,000+ order: $8.60 Lead time: 1 week Allows higher overheating protection compared to similar TEG’s (380°C) Taihuaxing TEP1-1264-1.5 ◦ Higher potential power output (5.9W) ◦ Similar pricing and lead time to TEP1-12635-3.4 Marlow TG 12-4-01L & 12-6-01L ◦ Lower maximum temperature (250°C) ◦ Higher prices ($12.50 to $20.00) ◦ No lead time Will order these additional TEG’s and use for testing/possible implementation Prevents overcharging of batteries Does not allow auxiliary power use when TEG is not actively providing power Does not incorporate MPPT, but was deemed most realistic/practical design Flow analysis was redone using the square geometry of the heat sink as a duct Results were compared to that of the stove’s current system Minimal difference was realized between the two designs Duct will be constructed of sheet metal and will be 2.6” square 16 14 12 10 8 6 4 2 0 -2 -4 Current Design Design was redone by varying the length of rod within the combustion chamber, as opposed to the length of rod outside the stove Length of rod outside the stove was set to 1cm Found that potential for overheating and destroying the TEG was much more likely Therefore, decided to keep original design Also, melting point of aluminum is not expected to be reached The TEG will be secured to the flat plate and heat sink through the use of four 10-32 socket cap screws Screws will pass through holes in the flat plate and heat sink larger than their diameter to prevent conduction from the hot side to the heat sink Each screw will be secured using a 10-32 hex nut and will be insulated on each side with a PTFE washer Heat sink and flat plate are larger than the footprint of the TEG to allow for screw through holes Estimated cost of prototype build is $101.67 Estimated cost of production (1000+) is $46.26 This is assuming all parts are purchased offthe-shelf; some components can be fabricated for a lesser cost