DRD Power Ltd

advertisement

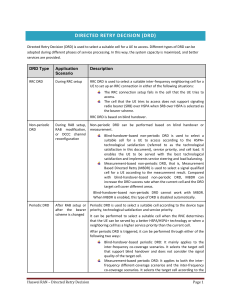

DRD Power Ltd Electric Power Generation from Waste Heat Sources by Organic Rankine Cycle Clive Whitbourn CEng FIChemE Roger Mallinson CEng FIChemE 22nd April 2010 New Ideas in Resource & Energy Efficiency - Peterlee © Copyright DRD Power Limited 2010 DRD Background o Energy & Resource Consultants o Energy Mapping & Audits – Project Identification o Renewable & Sustainable Technologies o Feasibility Studies © Copyright DRD Power Limited 2010 The Opportunity © Copyright DRD Power Limited 2010 Organic Rankine Cycle Boiler Expander Waste Heat Electricity Preheater CW Condenser © Copyright DRD Power Limited 2010 Benefits • • • • • • • Electricity savings ~£100kpa (200kW) CO2 savings = 700 tpa (200kW) Payback ~3 years Zero emissions Fully automatic No toxic substances Use of non-flammable refrigerants with low GWP © Copyright DRD Power Limited 2010 ORC Innovations • Low temperature heat source, ie 90°C and above • Innovative use of a compressor as an expander • No intermediate heat transfer fluid • Use of non-flammable refrigerants with low GWP © Copyright DRD Power Limited 2010 Project Milestones • • • • • Refrigerant Research - complete Turbine Research - complete Detailed Design - complete Construction of 200kW Demonstration Unit Commissioning and Operation – Q3. 2010 © Copyright DRD Power Limited 2010 Refrigerant Research • Choice of refrigerant influenced by: – – – – • • Environmental & Safety factors Engineering Thermophysical factors Commercial factors Hydrocarbons, halogenated hydrocarbons, and ammonia/water were examined Both single component and mixed fluids were considered © Copyright DRD Power Limited 2010 Turbine Research • Ideally, use a mass-produced turbine for reasons of cost and availability • No mass-produced turbines available, so a compressor run in reverse will be used • Research identified any necessary modifications eg lubricant flow © Copyright DRD Power Limited 2010 Modular Unit Rated 200kWe ORC Unit © Copyright DRD Power Limited 2010 Seeking Early Adoption Sites Waste heat sources >90°C Typical examples:• • • • Low Pressure Steam 1 – 2 tonne/hr Process Vapours Hot Water/Condensate 40 m3/hr (min) Hot process streams requiring cooling © Copyright DRD Power Limited 2010 Potential for your Site • Feasibility assessment • Estimate of electricity produced and value • CO2 savings © Copyright DRD Power Limited 2010 Project Support • Carbon Trust • Shell Springboard award in February 2009 - innovation and carbon reduction • NStar Finance © Copyright DRD Power Limited 2010 DRD Power Ltd Wilton Centre Wilton Redcar TS10 4RF Tel: 01642 430090 info@drdconsultants.co.uk Contacts: Clive Whitbourn Roger Mallinson © Copyright DRD Power Limited 2010 Temperature/Enthalpy Chart Temperature / Enthalpy Chart 180 160 liquid vapour pump preheater evaporator superheater turbine condenser heat source heat sink Turbine power Temperature (deg C) 140 120 100 80 60 40 20 0 200 250 300 350 400 450 Enthalpy (kJ/kg) © Copyright DRD Power Limited 2010 500 550