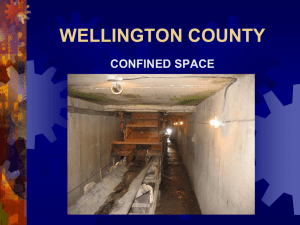

Confined Space

advertisement

New England Roofing Industry Partnership Confined Space Controlling Associated Hazards SUBPART C Confined Space Training Objectives After completing this unit, you will: – Be aware of the potential dangers of confined & enclosed spaces that roofers may encounter. – Be able to recognize potential hazards in these work areas. – Understand that you will need special training and equipment before working in an area that meets the characteristics of a confined space. 1 SUBPART C Confined Space References Construction Industry- 29 CFR 1926.21 (b)(6)(i) & (ii); Subpart C General Industry- 29 CFR 1910.146 2 SUBPART C Confined Space Construction vs. General Industry OSHA Construction Standards apply when a contractor is building a new confined space or reconfiguring an old space If existing confined space, and performing relining, repainting, cleaning, etc., then General Industry (1910.146 - Permit Required) regulations apply. Host employer (owner) should have permit required confined space program. 3 SUBPART C Confined Space Typical Confined Spaces Vent Gas Stack, Boiler, Furnace Pipeline, Pit, Pumping Station Reaction or Process Vessel, Mills Septic Tank, Sewage Digester Silo, Storage Tank, Barge Sewer, Utility Vault, Manhole Trenches, Shafts, Caissons 4 SUBPART C Confined Space How to Identify Confined Spaces Limited Openings for Entry and Exit Unfavorable Not Natural Ventilation Designed for Worker Occupancy 5 SUBPART C Confined Space Potentially Hazardous Roofing “Spaces” Some roofing work spaces may meet several of the hazardous characteristics, but not be defined as Confined Spaces: – Bottoms of drainage pits and other areas where you may be applying waterproofing coatings – In corners against walls – Crawl spaces – Under and around tanks and AC units – Any place where you are cramped, and generating solvent vapors and there is little or no air movement! 6 SUBPART C Confined Space Limited Openings for Entry/Exit Openings can often be as small as 18 inches in diameter. Difficult to enter with Self Containing Breathing Apparatus (SCBA) or other life-saving equipment. Difficult to remove downed worker. Exit from large openings may be difficult due to presence of ladders, hoists, etc. 7 SUBPART C Confined Space Unfavorable Natural Ventilation Lack of air movement can create an atmosphere much different than the outside atmosphere. Deadly gases can be trapped inside. May not be enough oxygen due to presence of other gases or chemical reactions such as rusting. 8 SUBPART C Confined Space Not Designed for Worker Occupancy Most confined spaces are not designed to enter and work inside on a regular basis. They are designed: – To store a product. – To enclose processes. – To transport products or substances. – For occasional worker entry for inspection, repair, cleanup, and maintenance. 9 SUBPART C Confined Space Hazards of Confined Spaces Not enough Oxygen Too much Oxygen Flammable Atmospheres Toxic Atmospheres Temperature Extremes Engulfment, Mechanical, Electrical Noise, Slick/Wet Surfaces, Falling Objects 10 SUBPART C Confined Space Not Enough Oxygen 19.5 % 15 - 19% 12-14% 10-12% 8-10% 6-8% 4-6% Minimum acceptable oxygen level. Decreased ability to work strenuously. Impaired coordination. Early symptoms. Respiration increases. Poor judgment. Respiration increases. Lips blue. Mental failure. Fainting. Nausea Unconsciousness. Vomiting. 8 minutes - fatal, 6 minutes - 50% fatal 4- 5 minutes - possible recovery. Coma in 40 seconds. Death. 11 SUBPART C Confined Space Too Much Oxygen When Oxygen level is above 23.5%: – Flammable & combustible materials burn violently when ignited. – This could mean hair, clothing, materials, and just about anything. Never use pure oxygen to ventilate. Never store or place compressed gas tanks in a confined space. 12 SUBPART C Confined Space Flammable Atmospheres Critical Factors: – Oxygen content in the air. – Presence of a flammable gas or vapor. – Presence of dust (visibility of 5’ or less). Proper air/gas mixture can lead to explosion. – Explosive mixtures occur between the Lower Explosive Limit (LEL) & the Upper Explosive Limit (UEL) Typical Ignition Sources: – Sparking or electric tool; Welding/Cutting – Smoking 13 SUBPART C Confined Space Toxic Atmospheres Can Form Due to product stored in a confined space: –Gases released when cleaning. –Materials absorbed into walls of confined space. –Decomposition of materials in the confined space. Due to work being done: –Welding, cutting, brazing, soldering. –Painting, scraping, sanding, degreasing. –Sealing, bonding, melting. 14 SUBPART C Confined Space Acceptable Safe Atmospheres Oxygen: 19.5% - 23.5% Explosive gases and vapors less than 10% of the LEL. Toxic gases and vapors less than OSHA’s permissible exposure limits. 15 SUBPART C Confined Space 16 Hydrogen Sulfide Gas Decomposition of materials. Human waste. Rotten egg odor at low concentrations. Possibly no warning at high concentrations. PPM 10 ppm 50 - 100 200 - 300 500 -700 >1000 Effect Permissible Exposure Level Mild Irritation - eyes, throat Significant Irritation Unconsciousness, Death Unconsciousness, Death Time 8 Hours 1 Hour 1 Hour 1/2 - 1 Hour Minutes SUBPART C Confined Space 17 Carbon Monoxide Odorless, colorless gas. Combustion by-product. Quickly collapse at high concentrations. PPM 50 ppm 200 600 1000-2000 2000-2500 Effect Permissible Exposure Level Slight Headache, discomfort Significant Irritation Confusion, nausea, stagger Unconsciousness Time 8 Hrs. 3 Hrs. 1 Hr. 2 Hrs. 30min. SUBPART C Confined Space What Makes This A Confined Space? 18 SUBPART C Confined Space 19 Causes of Confined Space Accidents – Bringing a known hazard into the space. – Failing to test, monitor & ventilate spaces. – Entering spaces without a permit program. – Failure to block, blind, bleed or isolate energy sources. – Failure to guard live electrical parts. – Failure to implement Lock-out/Tag-out. – Entry by unqualified & untrained personnel. SUBPART C Confined Space Who is Responsible? Contractor doing work. Owner of the space (the building owner). Shared responsibility. 20 SUBPART C Confined Space Shared Responsibility Construction Construction Contractor: Must comply with Construction Standards & General Duty Clause. Existing Building Owner: (Modify Space) Must inform contractor of hazards, precautions. Must answer contractor’s questions. Must discuss entry with contractor. May require use of company entry program. Contractor must train you in Owner program. Contractor is responsible for safety. 21 SUBPART C Confined Space 22 Permit-Required vs. Non-PermitRequired Confined Spaces Permit-Required: Space meets definitions, multiple hazards are present, work is not construction and/or Owner requires compliance with 1910.146 Standard. Non Permit-Required: Space meets definitions, but only atmospheric hazards are present and are controllable by ventilation and continuous monitoring is conducted. SUBPART C Confined Space Construction Regulations Construction - 1926.21(b)(6)(I): Requires instructions to employees who enter confined spaces. Construction - 1926.21(b)(6)(ii): Defines the confined and enclosed spaces which require instruction. Construction - 1926.352(g): Requires fire prevention measures when using fuel gas and oxygen in enclosed spaces. 23 SUBPART C Confined Space Construction Regulations Construction - 1926.353(b)(1): Requires exhaust ventilation when welding, cutting, or heating is performed in confined spaces. Construction - 1926.353(b)(2): Requires air line respirators and standby person whenever the means of access is blocked by ventilation equipment. 24 SUBPART C Confined Space Case Study: What went wrong? A worker sitting in a looped chain was lowered approximately 17 feet into a 21-foot deep vessel. Twenty seconds later he started gasping for air and fell from the chain seat face down into the accumulated water at the bottom of the manhole. An autopsy determined oxygen deficiency as the cause of death. 25 SUBPART C Confined Space 26 Review Questions True or False? 1. The most common type of hazard is atmospheric. 2. A confined space has limited openings for entry and exit, unfavorable natural ventilation, and is not designed for worker occupancy. 3. Oxygen at levels of 19.5% - 23.5%, and explosive gases and vapors less that 50% of the LEL, are acceptable atmospheres to enter. 4. You can’t have too much oxygen in a confined space. SUBPART C Confined Space Review Questions True or False? 5. Using a flammable solvent and a drop light in a confined space may lead to a potential explosion. 6. OSHA requires training for confined space entry. 7. OSHA does not require exhaust ventilation when welding, cutting, or heating is performed in confined spaces. 8. Monitoring the atmosphere before a worker enters and while they are inside is necessary to ensure a safe entry. 27 SUBPART C Confined Space Review Questions True or False? 9. Workers outside the space should never enter the space to rescue a fellow worker. 10. Before a space can be entered, all mechanical hazards and pipes which feed into the space must be locked and tagged out in a zero energy state. 28