Earth Retaining System

advertisement

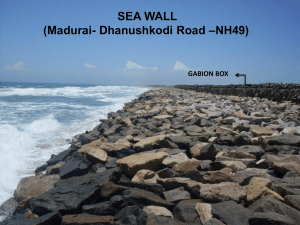

Hashemite University Department of Civil Engineering Foundation Engineering Dr. Omar Al-Hattamleh Earth Retaining System Earth slopes and earth retaining structures Used to maintain two different ground surface elevations Types of Earth Retaining Structure Rigid Gravity and semi gravity Walls •CIP Concrete Gravity Wall •CIP concrete cantilever Wall •Prefabricated Modular Gravity Wall •Crib Wall •Bin Wall •Gabion Wall Non Gravity Cantilevered Walls •Sheet pile Wall •Soldier pile and logging Wall •Slurry Wall •Tangent And Secant Wall •SMW Wall •Anchored Wall MSE WALLS •Segmented Pre-cast facing Sys. •Prefabricated Modular Block MSE •Geotextile, Geogrid MSE wall •Reinforced Soil Slope In Situ Reinforced Wall •Soil Nail •Micro-pile Cut Wall Construction Internally Stabilized Externally Stabilized Fill Wall Construction A cantilever gravity wall. CIP (Cast in Place) Concrete Cantilever Wall CIP (Cast in Place) Concrete Cantilever Wall Description Cast in place concrete cantilever/ counter forth wall consist of a steel reinforced concrete wall stem and base slab connected to for the shape of an inverted T. General 1. Typical Application: Bridge abutments, retaining walls, soil stabilization 2. Size requirements: Base width of ranges from 0.4 to 0.7 of the wall height 3. Typical Height Range: 2-9 m Cantilever wall; 9-18 m (counter forth Wall) Advantages 1. Conventional Wall System with Well established design procedure & performance characteristics 2. Concrete is very durable in many environments 3. Concrete can be formed, textured, and colored to meet aesthetic requirements CIP Concrete Cantilever Wall Cont. Disadvantages 1. Requires relatively long construction period: formwork must be erected & concrete poured and allowed to cure before backfill loads 2. 3. Costly : a) Required selected backfill if not available near the site b) May need temporary excavation support c) Deep foundation support Wall system is rigid and its sensitive to total and differential settlements Gabion Wall Description Compartment unit filled with stone that is 100 to 200 mm in size. Each unit is a rectangular basket made of galvanized steel, geosynthetic grid or polyvinylchloride (PVC) coated wire. Each gabion units laced together on site and filled with selected stone General 1. Typical Application: Retaining walls, Slope stabilization, bank stabilization 2. Size requirements: Base width of ranges from 0.5 to 0.7 of the wall height 3. Typical Height Range: 2-8m Advantages 1. Wall System is flexible and can accommodate large and differential settlements with out distress 2. Wall appearance well suited to rural areas 3. Wall flexible, therefore, suited for application in high seismicity area 4. Wall pervious, therefore, well suited foe bank stabilization applications Gabion Wall Cont. Disadvantages 1. 2. 3. Source of stone must be available Gabion wire are subjected to corrosion in aggressive soils Abrasion of the gabion baskets may occur in water way application Requires significant manual labor Not cost effective for temporary applications 4. 5. Sheet Pile Wall Sheet Pile Wall Sheet Pile Wall Description Consist of driven, vibrated, or pushed, interlocking steel or concrete sheet pile sections. The required depth of embedment (i.e. length of sheet pile below final excavated grade) is evaluated based on the assumption that the passive resistance of the soil in front of the wall plus flexural strength of the sheet pile can resist the lateral forces from the soil behind the wall General 1. Typical Application: Retaining walls, Slope stabilization, excavation support Marine walls, docks 2. Size requirements: N/A 3. Typical Height Range: 2-5m Advantages 1. Conventional Wall System with Well established design procedure & performance characteristics 2. Wall system can be used for application in which wall can penetrates below ground water table 3. Work area inside wall face is not required 4. Wall system is suitable for temporary applications Sheet Pile Wall Cont. Disadvantages 1. Requires specialized equipment 2. Driven sheet pile is noisy and it can be introduce vibration 3. Difficult to drive sheet in hard or dense or gravelly soil 4. Wall height is limited based on required structural sections 5. Wall system may undergo relatively movements which may be detrimental to nearby structure SMW Wall (Soil Mixed Wall) Description Consist of overlapped soil-cement columns in which in situ soils are mixed with a cement slurry or other hardening agent. A multiple axis auger and mixing paddles are used to construct overlapping soil cement columns without soil removal or unmixed zones between columns. General 1. Typical Application: Retaining walls, excavation support 2. Size requirements: typically 1.0 m 3. Typical Height Range: 6-24 m with anchors Advantages 1. Reduce excavated spoil is produced 2. Is adaptable to an irregular installation arrangement SMW Wall (Soil Mixed Wall) Cont. Disadvantages 1. Design procedures are not well established 2. Construction of wall system requires specialty contractor and equipment vibration 3. Quality control/ quality assurance protocol is not well documented for this wall system 4. Disposal of excavated spoil resulting from soil mixing process may be costly do to environmental restrictions Soil Nailed Wall Soil Nailed Wall Description In Situ soil reinforcement technique wherein passive inclusions (soil nails) are placed into the natural ground at relatively close spacing (1-2 m) to increase the strength of the soil mass. Construction staged from top to down and after each stage of excavation, the nails are installed, drainage system are constructed and shotcrete are applied to the excavation face. General 1. Typical Application: Retaining walls, soil stabilization, excavation support 2. Size requirements: soil nail length typically from 0.6- 1.0 m of the wall height 3. Typical Height Range: 3-20 m Advantages 1. An unobstructed working space can be achieved on the excavation side of the wall 2. Surface movements can be limited by installing additional nails or by stressing nails in upper level to small percentage of working loads 3. Wall system is adaptable to varying site conditions 4. Is well suited for construction in areas of limited head room 5. Wall embedment is nor required 6. Suitable for temporary applications SMW Wall (Soil Mixed Wall) Cont. Disadvantages 1. Construction of wall system requires specialty contractor 2. Required permanently dewatering in case of the present of ground table 3. Closed space nail May interface underground utilities 4. Nail capacity may be difficult to develop in some cohesive soil Segmental, Precast Facing Mechanically Stabilized Earth Walls Segmental, Precast Facing Mechanically Stabilized Earth Walls Segmental, Precast Facing Mechanically Stabilized Earth Walls Description A segmental, pre-cast facing mechanically stabilized earth wall employs metallic (strip or bar mat) or geosynthetic (geogrid or geotextile) reinforcement that is connected to a precast concrete or prefabricated metal facing a panel to create a reinforced soil mass. Facing Panel are typically square, rectangular, hexagonal or cruciform in shape General 1. Typical Application: Bridge abutments, retaining wall, slope stabilization 2. Size requirements: minimum reinforcement length of 0.7 m of the wall height 3. Typical Height Range: 3-20 m Advantages 1. 2. 3. 4. 5. 6. Rapid construction; does not required specialized labor Limited foundation preparation Flexible; accommodate large differential settlement Reinforcement is light and easily to handle Flexibility in choice facing and architectural finishes Suitable for regions in high seismicity Segmental, Precast Facing Mechanically Stabilized Earth Walls Cont. 1. Disadvantages Not economical for cut application due to additional cost in temporary excavation Requires relatively large base width Use of metallic reinfrorcment requires a minimum electrochemical requirements for corrosions Allowable loads for geosynthetic reinforcement must be reduced to account for creep, durability, and construction damage Not appropriate for 2. 3. 4. 5. 6. If we need access to underground utilities Locations subjected to scour Place involving significant horizontal curvature Not cost effective for temporary applications RSS Reinforced Soil Slope Description These systems incorporating planner reinforcement, typically geotextile or geogrid in construct the earth slope face inclination less than 70o. The reinforcement is laid down alternately with horizontal layers of compacted soil. General 1. Typical Application: Slope stabilization, embankment construction Sound/ Noise absorbing embankment wall 2. Size requirements: min. reinforcement length of 0.5-1.0m of the wall height 3. Typical Height Range: 3-30 m Advantages 1. 2. 3. 4. 5. 6. 7. 8. Rapid construction; does not required specialized labor Limited foundation preparation Flexible; accommodate large differential & total settlement Reinforcement is light and easily to handle Extremely Flexible suited for seismic zones Suitable for regions in high seismicity Vegetation of the slope possible Can be used for construction of very height embankment over 30m RSS Reinforced Soil Slope Cont. Disadvantages 1. Non vertical slope increase right of way compared to a vertical wall 2. Requires relatively large base width 3. Geotextile and geogrid requires relatively large base width 4. Geotextile and geogrid life is reduced due to exposure to ultraviolet light Crib Wall http://www.concrib.com.au/gallery_cribwall.htm Crib Wall Crib Wall Crib Wall Segmental Retaining Wall Gabion Gabion Bin Wall http://www.contech-cpi.com/default.aspx CONSTRUCTION OF SECANT PILE WALL http://www.lta.gov.sg/projects/images/Secant%20Final.pdf CONSTRUCTION OF SECANT PILE WALL