Bio fuel presentation 130214

advertisement

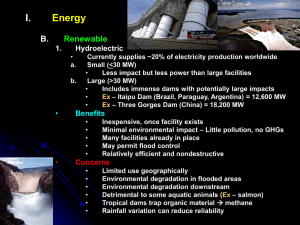

Renewable Energy for Rail Industry Construction sites A presentation to the Rail Industry Environmental Forum by Colin Campbell – Director - Biofuels (GB) Ltd Presentation Contents 3. Renewable energy generators for Railway construction sites 4. Liquid Biomass 5. Our Refineries 6. UK Rapeseed oil 7. ISCC Proof of Sustainability 8. R & D Fuel Engineering by Oxford University Science Park 9. Network Rail & BAM Trials 10. Renewable Obligation Certificates 11. The Carbon Reduction Commitment (CRC) 12. Air Quality and Emissions Zones 13. Co op Head Quarters Manchester 14. Generator Hire Partners 15. Watson Halls – National Fuel Distribution 16. Commercial Agreements 17. Biofuels and Oils Renewable energy from liquid biomass diesel generators Rapeseed Methyl Esters – Liquid Biomass for diesel engines • • • • • • • • • • Made to EN14214 OEM Diesel Engine Warrantied Freezes at -15C Tested by UK Hire Companies Biodegrades in 21 days when spilled Lower spill clean up costs Similar performance to DERV ISCC Certified “sustainable” Minimum 43% CO2 Savings Lower Noxious exhaust Emissions 4 EU Liquid Biomass Refineries - 500 Million Liters Production capacity per annum Only ISCC Certified “sustainable” degummed rape seed oil from UK and EU farmers Independently Audited by ISCC as sustainable biomass with reduced CO2 emissions • • • • • • • • • • • • • ISCC Proof of Sustainability Certificates Actual 42.9% Carbon Saving recorded Known field rape seed crop of Origin No association with deforestation No association with change of land use Certified Winter break crop 66% of rape seed crop goes to animal feed Minimum EU carbon saving 35% Certified Renewable Energy ISCC online Certification number UK and EU field crops of origin Rape seed oil is poisonous 200,000 UK & EU Jobs R & D Fuel Engineering by Oxford University Science Park Fuel Engineers • largest concentration of fuel research scientists in Western Europe • UK Climate and Emissions additive package added to the liquid biomass to improve the poor fuel economy and increased NOx emissions levels associated with burning conventional biodiesel • Formal Emissions Testing conducted to ISO 8178 by Intertek Tickford. Validation of Tier III emissions compliance on mobile generators • City of London Corporation funding from Mayor of London to support emissions testing • Unique tracer agent which cannot be removed to validate use re claiming of ROCS subsidies 8 Tested and Proven in a Scottish winter by BAM Nuttall on Network Rail EGIP • • • • • • • Full Performance Trial Tested to -12C Similar Fuel economy Lower exhaust emissions No engine failure Quieter engine noise Renewable Energy Eligible for 1.5 Rocs per MW/hr. worth between 24p and 30p per liter Renewable energy from liquid biomass is exempt from the CRC Tax CRC Energy Efficiency Scheme The CRC Energy Efficiency Scheme started in April 2010. It’s designed to encourage large public and private sector organisations to reduce their carbon dioxide (CO2) emissions through energy efficiency. Phase 1 of the scheme runs from 1 April 2010 to 31 March 2014. Participants for Phase 1 should have registered by 30 September 2010. Phase 2 will start on 1 April 2014. Organisations will qualify for Phase 2 between 1 April 2012 and 31 March 2013 if: • they have at least one settled half hourly electricity meter • and more than 6000 megawatt hours (MWh) of qualifying electricity supplied on the settled half hourly market. If your organisation meets these criteria you must register for Phase 2 of the scheme between 4 November 2013 and 31 January 2014. Some public bodies must participate in CRC no matter how much electricity they consume. These are known as mandated participants. Lower exhaust emissions from diesel engined construction equipment • • • • Lower PM 2.5 Lower PM 10 Lower CO2 NOx Neutral The Co op - In good company – Liquid Biomass producing Renewable Energy Co-operative Group HQ, One Angel Square, Manchester Sustainable measures, particularly to conserve energy, mean the Co-operative Group’s new headquarters will produce 80 per cent less carbon and halve its energy use In addition to the recovered heat, 764kW of waste heat from two 400kW combined heat and power (CHP) units is used to heat the fresh air. These are fuelled by rapeseed oil liquid biomass produced on the Co-op’s own farms. The CHP units also provide cooling through an absorption chiller. Approved for use by UK Leading Power Rental companies in diesel generators Watson Halls - The National Fuel Supplier - Liquid Biomass available nationally Commercial Agreements • • • • Platt's pricing linked to gasoil Existing Hall Fuels credit terms National UK delivery Fuel Management Service www.biofuelsandoils.com Biofuels (GB) Ltd