Odour and Air Management Studies

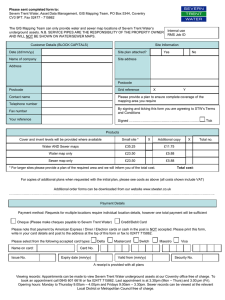

advertisement

Odour and Air Management Studies Key Tool in Determining Effective Odour Control Solutions Presented by: Wayne Wong, M.A.Sc, EIT Project Team 2 Yuko Suda, P.Eng. – Kerr Wood Leidal Associates Ltd. Ted Steele, P.Eng. – Kerr Wood Leidal Associates Ltd. Karl Mueller, P.Eng. – Kerr Wood Leidal Associates Ltd. Chris Hunniford, PE – OCTC, a V&A Company September 28, 2011 Introduction to Sanitary Odours 3 Sewer odours can be found everywhere! • Gravity sewers • Air vents • Pump stations • Forcemains • Manholes • Wastewater treatment plants Operational headache and nuisance Costly problem for municipalities September 28, 2011 Source of Odours in Sanitary Systems 4 Odour Generation + Odour Release = Problem Odour Generation Combination of organic waste material and bacteria in the sewer generates hydrogen sulfide (H2S) and volatile organic compounds (VOCs) Especially problematic in collection systems with large detention times Odour Release Local pressurization of the air space above sewage results in odourous air being released from a contained space (sewer, manhole, tanks) September 28, 2011 Odour Generation 5 Occurs where there are large concentrations of organic waste materials and bacteria in the collection system Odour generation is accelerated under the right environmental conditions - Anaerobic conditions (typical in long forcemains or in collection systems with long hydraulic detention times) Odour generation is generally difficult to avoid September 28, 2011 Odour Release 6 Odourous compounds generally exist within the collection system headspace. These odourous compounds become a nuisance when there is pressurization and air movement which transport these odourous compounds from the headspace and released into the environment There are a number of physical mechanisms that result in pressurization. The primary mechanism is air movement in the sewer due to the effects of friction drag September 28, 2011 Air Movement in Sewers 7 The primary force for air movement in gravity systems is the friction between the sewer headspace air and the moving wastewater below. Resistance to air movement due to friction between air and pipe wall An idealized velocity gradient can be developed based on these simple boundary conditions September 28, 2011 Air Movement in Sewers 8 Friction factor between water and air varies depending on factors such as turbulence and rough water surfaces (high friction factor) Slower moving, quiescent water surfaces will generally result in a lower friction factor. The flow rate of air that is conveyed is proportional to the air velocity in the headspace and the cross sectional area of the headspace September 28, 2011 Pressurization in Sewer Headspace 9 Occurs when there are abrupt changes in rate of air flow in the sewer High flow rate of air from one section colliding with air in a downstream section that has a lower air flow rate Change in air flow rates can be caused by changes in pipe slope and/or restrictions in the sewer headspace When an area of pressurization coincides with a vent or manhole, sewer air will be expelled at that point September 28, 2011 Other Factors That Can Contribute to Odour Ventilation Problems 10 Change in atmospheric (barometric) pressure or ambient temperature (air density change) can cause air movement in/out of the collection system Strong surface winds can draw air out of the collection system via eduction Decrease in pipe diameter in downstream pipe sections Opposing or perpendicular flows entering a junction can cause a temporary backup of air September 28, 2011 Other Factors That Can Contribute to Odour Ventilation Problems 11 Ventilation effects are more pronounced in collection systems with fewer service connections, vents and manholes, where there are fewer relief points for expelling air Ventilation effects can be most severe at inverted siphons, full-flowing or surcharged sewers and pump stations where airflow can be stopped completely, creating high pressures in the sewers September 28, 2011 Developing Solutions 12 Conventional solution has been to seal manholes or install carbon scrubbers This results in increased air pressurization of the overall collection system and causes air to be expelled elsewhere. This is a reactive approach which shifts the problem to another location rather than solving the problem September 28, 2011 Developing Solutions 13 Completing an odour and air management study to determine the most effective mitigation strategy is a more proactive approach A comprehensive odour and air management study can be used to: • Determine the root cause of odour emissions • Develop options to eliminate problems while minimizing capital and operating costs. September 28, 2011 Odour and Air Management Study 14 An effective odour control and air management study includes: • Monitoring program (H2S, VOCs, differential air pressure) • Ventilation modeling (areas of pressurization, air flow rates, ventilation dynamics, release points) • Hydraulic modeling (displacement effects) Based on the above study, an evaluation can be conducted to develop the most effective strategy for mitigating odour September 28, 2011 Differential Pressure Monitoring 15 September 28, 2011 Hydrogen Sulphide Monitoring 16 September 28, 2011 Odour and Air Management Study 17 An evaluation can be conducted to develop the most effective strategy for mitigating odour emissions Key Considerations: • Cost • Feasibility of implementation • Environmental impacts (hazardous chemicals, noise, etc.) • Overall treatment effectiveness September 28, 2011 Active Odour Control Facilities 18 An active odour control facility draws air from the sewer using a fan, treats it, and releases it to the atmosphere. Types of treatment include biofilters, activated carbon adsorbers, and chemical scrubbers etc. Drawing air in from the sewer with a blower and treating it creates an area of negative pressure (zone of influence) in the vicinity of the collection system within the sewer. September 28, 2011 Case Study – Highbury Interceptor 19 Metro Vancouver The Highbury Interceptor is owned and operated by Metro Vancouver. Combined sewer (expected to be fully separated by 2050) Total length = 6 km Pipe diameter – 2,900 mm Significant odour complaints and headspace pressurization issues Noise issues during winter storms in which large volumes of air are expelled from vents Manhole lids have been observed to be blown off September 28, 2011 Case Study – Highbury Interceptor 20 Metro Vancouver Monitoring of differential pressure, H2S, and VOCs were carried out during both wet and dry weather periods Differential pressure indicated significant positive pressure occurs throughout the Highbury Interceptor Ventilation modeling estimated the drag airflow at 10,000 cfm Downstream end of the interceptor is a siphon, and no air can be conveyed beyond this point, creating an area of high pressurization September 28, 2011 Case Study – Highbury Interceptor 21 Metro Vancouver Hydraulic modeling indicated that sections of sewer becomes completely isolated from upstream, downstream, and tributary sewers during high flow (backwatering) The ventilation model estimated that a typical storm could displace up to 7,000 cfm Model indicated that as sewage level increase, a large amount of air can only be displaced at a few small vents (high pressure and high air discharge velocity) September 28, 2011 Case Study – Highbury Interceptor 22 Metro Vancouver KWL/OCTC project team proposed three active odour control facilities along the interceptor sewer The main active odour control facility, with a design treatment capacity of 10,000 cfm, would have a zone of influence of approximately 4.6 km September 28, 2011 Conclusion 23 An odour control and air management study that includes monitoring, ventilation modeling, and hydraulic modeling is key to determining the root cause of odour complaints and can be used to develop a cost effective solution for controlling odour in a sanitary collection system. September 28, 2011 Questions? 24 Contact Information Wayne Wong, M.A.Sc., EIT Kerr Wood Leidal Associates Ltd. wwong@kwl.ca (604) 293-3274 September 28, 2011