RB 230212 learning from gmp inspections

advertisement

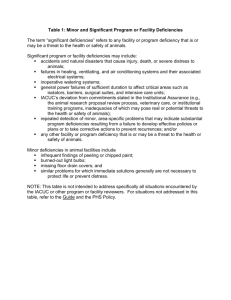

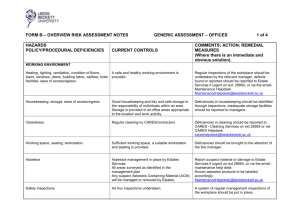

Learning from GMP Inspections. Richard Bateman QA Specialist Pharmacist East and South East England Specialist Pharmacy Services Overview MHRA Inspection Process Risk Based Inspections – 2008 onwards Learning from deficiencies NHS constraints MHRA publication of summaries London and South East collations since 2004 NHS specific issues and trends Sharing via local and national networks The same findings or are there changes? Have the goalposts really shifted? Common Deficiencies What do you think the most common deficiencies are? Are there new / emerging topics at inspections? Can / should we share information to increase learning? What are the barriers to addressing deficiencies effectively and in a timely manner? MHRA Inspection Data No specific category for repacking / overlabelling Need to focus on specific areas and some not so relevant – included to give “big” picture Quality Management Early years data low incidence Now generally first or second in frequency Change in practices or change in inspection emphasis? Increased focus on QMS and RM (ICH Q 8/9/10) Risk based inspection process Quality Systems Self Inspection Complaint and product recall Investigation of anomalies Quality Management CAPA Change Control Quality Management (RM) Quality Management CAPA – we may have systems but do we really do both parts? Can we show this? RM should be proactive not reactive Statements on exception reports? Recalls – MHRA, Regional System, Company Alerts and communications. Training and training records Personnel Key duties Personnel Training Records – do we really show competency? Checking – evidence, logs and statistics? It is a simple process – until it goes wrong! Design and maintenance of facilities Control of environment Premises and Equipment Design and maintenance of equipment Calibration and testing of equipment Premises and Equipment NHS Problem We know this – so do MHRA! Manufacturing Documentation Sterility assurance Contamination – microbial Production Contamination – physical Segregation / clearance Environmental monitoring In process controls Production Completion and accuracy of batch documentation – signatures, timeliness of completion, accuracy re suppliers Segregation and line clearances – records, checking?, how thorough? Products and leaflets – packing line, photocopier, storage areas Don’t forget storage areas as well Documentation specifications Finished product testing Computerised systems Quality Control Sampling materials • stability, chemical & microbial Testing of starting materials and packaging components Quality Control Starting Materials – approval, specification, contract changes, out of stocks and substitutions Release procedures – sampling, testing Technical Agreements with suppliers / contractors Starting materials / APIs Supplier / contractor audit Materials Management TSE compliance Warehousing / distribution Materials Management Starting materials – see QC Technical Agreements – customers, contracting for services Contingency Arrangements Warehousing and distribution – GDP issues Process Analytical Equipment Validation Computerised systems Cleaning Validation Master Plan and associated documentation Validation Labelling systems – access, validation, checking systems Barcoding? VMP Cleaning Equipment? Regulatory Compliance Failure to respond to previous inspection findings • NB resources, timescale, RBI process? Non compliance with terms of licenses Related GDP Deficiencies General Storage – temperature control and monitoring Mapping, records, deviation handling, SOPs, returns Cold storage and transport – temperature control and monitoring As above, in transit if applicable – receipt and dispatch. NB returns? Systems for returns and recalls In house and MHRA / company led. Communication within host organisation? Testing of SOP? Related GDP Deficiencies Counterfeiting Issues and controls NHS contracting process gives good protection Supplier bona fides Destruction of packaging SOP Would staff receiving know what to look out for – training and records Questions revisited What do you think the most common deficiencies are? Are there new / emerging topics at inspections? How can we improve the way we share information to increase learning? How can we overcome the barriers to addressing deficiencies effectively and in a timely manner?