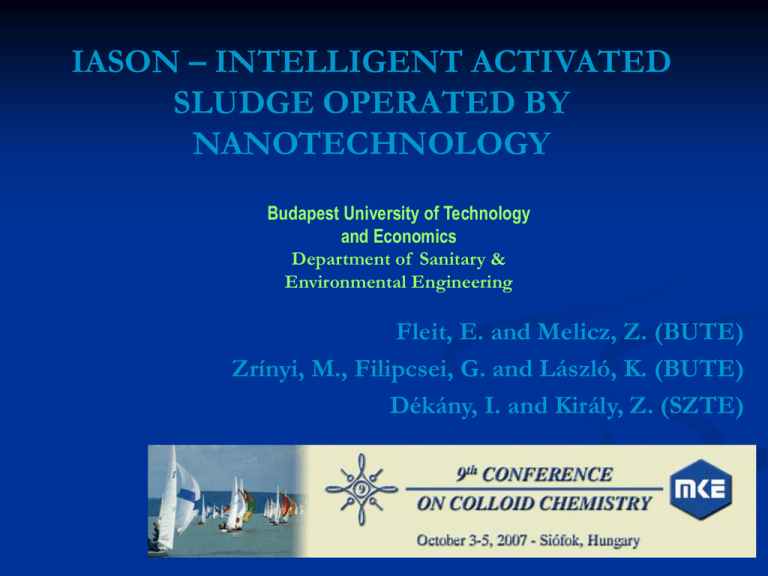

iason – intelligent activated sludge operated by nanotechnology

advertisement

IASON – INTELLIGENT ACTIVATED SLUDGE OPERATED BY NANOTECHNOLOGY Budapest University of Technology and Economics Department of Sanitary & Environmental Engineering Fleit, E. and Melicz, Z. (BUTE) Zrínyi, M., Filipcsei, G. and László, K. (BUTE) Dékány, I. and Király, Z. (SZTE) Problem exposition (colloids vs wastewater treatment) Do we know enough (from each other)? State-of-the-art in wastewater treatment „High-tech low-tech” dilemmas Hungarian context One new idea in old environment – IASON Results Conclusions Innovation chain (lessons learned) Do we have mutual problems? Particle size Dissolved (µm) <0,08 Organic material (%) COD 25 TOC 31 Grease 12 Protein 4 Carbohydrate 58 Rate of 0,39 oxidation Colloidal 0,08-1,0 Quasi-colloidal 1-100 Settleable >100 15 14 51 25 7 26 24 24 45 11 34 31 19 25 24 0,22 0,09 0,08 Definitely we do… A typical colloid problem: foaming and scum (cream) formation (on full scale) URBAN WATER INFRASTRUCTURE (HUNGARY): UNPRECEDENTED INVESTMENTS % of the total population 100 90 80 70 60 50 40 Population supplied by public taps located along streets Access to public water supply Access to sewerage including population living on sewered areas but not using this service 30 20 10 Access to sewerage 0 1950 1955 1960 1965 1970 1975 1980 1985 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 Wastewater treatment in Hungary - 1990 Wastewater treatment in Hungary - 2003 Wastewater treatment in Hungary - 2015 Hungarian Wastewater Master Plan: strategy with dilemmas Scheduling (scenarios) Cost efficiency (taking EU technologies without adoption) Emissions and water quality impacts Long-term (but hidden) links between wastewater treatment and colloid sciences Late lessons from early warnings… Colloid size substrates (foams, creams, emulsions, etc.) Colloid size reactants (biofilm, ESP, activated sludge flocs, etc.) Kinetic and financial problems Starting point – a key element in biological wastewater treatment remains uncontrolled Suspended cell bioreactors (activated sludge systems) Particle size distribution ? Diffusion limitation ? Ratio of floc and filament former bacteria ? Technological functions ? A novel concept - IASON I – A – S – O – N - Intelligent Artificial Sludge Operated by Nanotechnology An example: the Bardenpho IASON process control process Raw wastewater Treated effluent Anaerobic Anoxic Oxic Project objectives Control and design of floc size distribution and settleability (density) Control of substrate and electron acceptors (O2 and/or NO3) within the floc Biofilm formation (nitrification/denitrification) Direct regulation of technological functions in microscopic dimensions by nanotechnology (microreactor development) Wastewater bacteria on microscopic carrier materials (PVA-PAA/starch) (biofilm development after 1 week) A 100 m The first step: immobilization on designed microreactors Immobilization with adsorption Ionic bounds Covalent bounds Cross-linking Matrix entrapment Microcapsulation Combined methods Heterotrophic bacteria (South-Pest WWTP) on PVA-PAA hydrogels (400x) Growth of selected (technological aims) bacteria on hydrogels Nitrifying bacteria 100x Budapest Sewerage Works Cumulated O consumption (mg/l) (mgO O22 consumption Cummulative 2) Comparative respirometric experiments (AS and IASON) 130 Activatedsludge sludge(mixed culture) Activated Colonized PVA-PAA Colonizated PVA-PAA 120 110 100 90 80 70 60 50 0 2 4 6 8 10 12days Days Nitrification efficiency (%) (%) efficiency Nitrification Nitrification efficency of biomass grown on PVAPAA gels PVA-PAA 1 PVA-PAA 2 PVA-PAA 3 100 90 Continuous upflow reactor 80 70 60 50 40 30 20 10 0 0 5 10 15 20 days Days Development of active microreactors 1. day 2. week 3. week Functioning of autotrophic system (upon 3 weeks of biofilm developmen) 35 mg/l Nyers 8,8 8,8 8,6 8,6 8,4 8,4 8,2 8,2 8,0 8 7,8 7,8 7,6 7,6 7,4 7,4 30 Nyers Tisztított 25 20 15 Tisztított Nyers 10 5 Nyers Tisztított Nyers Tisztított Tisztított 0 pH1 NH3-N NH 4-N NO2-N NO 2-N NO3-N NO 3-N oP oP IASON - future nanotechnological design objectives Establishment of microscopic size reactors (contolled gradients) Substrate Oxygen Aerobic layer Anaerobic/anoxic layer End-product Solid carrier material (hydrogel) Conclusions „Traditional” technologies/pollutants Changes of wastewater composition (rapid) New type of pollutants Conceptual change and novel opportunitie Nano- and biotechnology Design of wastewater composition Professional background (R+D and education)