TOC in bottom ash

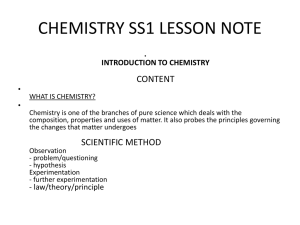

advertisement

Management of Waste Incineration Residues Title of transparency: Arial 26pt bold Double spaced: Arial 22pt bold 2nd SYNERGIA Forum Sub-title: Arial 18pt bold Several lines possible. June 10, 2010, Athens National Hellenic Research Foundation INSTITUTE FOR TECHNICAL CHEMISTRY / THERMAL WASTE TREATMENT DIVISION J. Vehlow Institute for Technical Chemistry -Thermal Waste Treatment Division KIT – University of the State of Baden-Wuerttemberg and National Research Center of the Helmholtz Association www.kit.edu MSW 1000 furnace / boiler 2-5 Fe 20 - 50 non Fe 5 - 15 150 – 250 filter scrubber < 0,05 7 – 15 0,5 - 2 (wet with effluents) 12 – 18 (wet without effluents) 20 – 40 (dry) flows of solid masses in a MSWI plant in kg J. Vehlow INSTITUTE FOR TECHNICAL CHEMISTRY THERMAL WASTE TREATMENT DIVISION glass gehlenite (Ca2Al2SiO7) iron oxide (Fe3O4) minerals in bottom ash J. Vehlow INSTITUTE FOR TECHNICAL CHEMISTRY THERMAL WASTE TREATMENT DIVISION selected elements in bottom ash and lithosphere J. Vehlow INSTITUTE FOR TECHNICAL CHEMISTRY THERMAL WASTE TREATMENT DIVISION landfill landfill class11 class parameter parameter LOI LOI TOC TOC %% % % DEV S4 12457-4 DEV DIN S4 EN sol.fraction fraction sol. el.cond. cond. el. Cl Cl Cu Cu Zn Zn Cd Cd Pb Pb % % mS/m mS/m mg/l mg/l mg/l mg/l mg/l mg/l mg/l mg/l mg/l mg/l landfill landfill class 22 class 33 11 55 33 33 000 11000 66 000 55000 11 22 0,05 0,05 0,2 0,2 55 55 0,1 0,1 11 utilisation utilisation (LAGA M20) M20) (LAGA 11 600 600 250 250 0,3 0,3 0,3 0,3 0,005 0,005 0,05 0,05 German standards for landfill and utilisation J. Vehlow INSTITUTE FOR TECHNICAL CHEMISTRY THERMAL WASTE TREATMENT DIVISION day 1 day 2 day 3 day 4 day 18 day 19 day 20 day 21 0 0.2 0.4 0.6 TOC in wt % 0.8 1.0 TOC in bottom ash (ASR co-combustion in full scale) J. Vehlow INSTITUTE FOR TECHNICAL CHEMISTRY THERMAL WASTE TREATMENT DIVISION day 1 day 2 day 3 day 4 day 18 day 19 day 20 day 21 0 1 2 3 4 5 6 PCDD/F in ng[TE]/kg 7 8 PCDD/F in bottom ash (ASR co-combustion in full scale) J. Vehlow INSTITUTE FOR TECHNICAL CHEMISTRY THERMAL WASTE TREATMENT DIVISION PCDD/F in ng(TE)/kg 10000.0 1000.0 100.0 10.0 1.0 soil 0.1 1985 1990 1995 2000 2005 PCDD/F in grate ashes between 1985 and 2005 J. Vehlow INSTITUTE FOR TECHNICAL CHEMISTRY THERMAL WASTE TREATMENT DIVISION log (concentration) DIN EN 12457 - 4 metals 3 4 5 6 7 8 9 10 11 12 13 pH pH influence on heavy metal leaching J. Vehlow INSTITUTE FOR TECHNICAL CHEMISTRY THERMAL WASTE TREATMENT DIVISION day 1 day 2 day 4 day 18 day 19 day 20 day 21 9 10 11 12 pH in eluate fresh 13 14 aged pH reduction by aging J. Vehlow INSTITUTE FOR TECHNICAL CHEMISTRY THERMAL WASTE TREATMENT DIVISION pH influence on leaching of Pb J. Vehlow INSTITUTE FOR TECHNICAL CHEMISTRY THERMAL WASTE TREATMENT DIVISION raw ash <32 mm sieve 32mm >32 mm sieve 10mm <10 mm impact crusher ferrous scrap magnetic separation nonferrous eddy current scrap separation air classifier magnetic separation ferrous scrap eddy current separation sieve 32mm >10 mm nonferrous scrap >32 mm belt scale belt scale storage for maturing to furnace disposal utilisation (source: Zwahr 2005) treatment of bottom ash for utilisation (Hamburg) J. Vehlow INSTITUTE FOR TECHNICAL CHEMISTRY THERMAL WASTE TREATMENT DIVISION DEV S4 results of 26 bottom ash samples J. Vehlow INSTITUTE FOR TECHNICAL CHEMISTRY THERMAL WASTE TREATMENT DIVISION Cr Ni Cu Zn Pb 0.1 1 10 100 results in % of LAGA limit for utilisation bottom ash rec. concrete gravel DIN EN 38414-4 leaching of various materials J. Vehlow INSTITUTE FOR TECHNICAL CHEMISTRY THERMAL WASTE TREATMENT DIVISION boiler filter APC • washing • metal separation • sieving • aging • fusion bottom ash treatment for quality improvement J. Vehlow INSTITUTE FOR TECHNICAL CHEMISTRY THERMAL WASTE TREATMENT DIVISION Ni Cu Zn Pb 0.1 1 10 100 results in % of LAGA limit for utilisation aged sintered fused DEV S4 leaching of treated grate ashes J. Vehlow INSTITUTE FOR TECHNICAL CHEMISTRY THERMAL WASTE TREATMENT DIVISION Finland Hungary Czech Republic Portugal Belgium Spain Austria Sweden Denmark UK Italy Netherlands France Germany 0 1,000 landfill 2,000 3,000 bottom ash in 1000 Mg metals 4,000 5,000 utilisation bottom ash management in selected EU countries J. Vehlow INSTITUTE FOR TECHNICAL CHEMISTRY THERMAL WASTE TREATMENT DIVISION PCDD/F concentration in mg/kg (PCDD/F in ng[TE]/kg) selected pollutants in bottom and filter ash J. Vehlow INSTITUTE FOR TECHNICAL CHEMISTRY THERMAL WASTE TREATMENT DIVISION boiler • washing • metal separation • sieving • aging • fusion filter APC • solidification • stabilisation • vitrification • leaching/sintering • asphalt filler • salt mine backfilling • central storage for future mining boiler and filter ash management options J. Vehlow INSTITUTE FOR TECHNICAL CHEMISTRY THERMAL WASTE TREATMENT DIVISION 2. scrubber 1. scrubber filter boiler Hg recovery grate ash + 3R product extraction binder liquid extrusion heavy metal recovery scheme of the 3R Process J. Vehlow INSTITUTE FOR TECHNICAL CHEMISTRY THERMAL WASTE TREATMENT DIVISION conclusions bottom ashes - can be utilized as building material e.g. in road construction - secondary treatment pays only if a high quality of the products can be achieved fly ashes - disposal depends on local conditions - inertisation processes are developed - storage for future mining gas cleaning strategy - should be selected according to the best residue disposal option J. Vehlow INSTITUTE FOR TECHNICAL CHEMISTRY THERMAL WASTE TREATMENT DIVISION