An Overview of Highway Construction in Atlantic Canada

advertisement

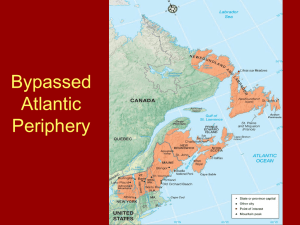

An Overview of Highway Surface Mix Construction in Atlantic Canada 2006 CUPGA Meeting. Charlottetown, PEI Provincial Highway Inventory Prince Edward Island Primary Highway = 60% Secondary Highway = 40% Newfoundland Primary Highway = 50% Secondary Highway = 50% New Brunswick Primary Highway = 50% Secondary Highway = 50% Nova Scotia Primary Highway = 20% Secondary Highway = 80% Highway Inventory Primary Roads vs. Secondary Roads Percent 80 70 60 50 40 30 20 10 0 Prince Newfoundland Edward Island Labrador New Brunswick Nova Scotia 2006 Tonnage Breakdown Prince Edward Island New Construction = 0 Rehabilitation = 250,000 Newfoundland New Construction = 137,000 Rehabilitation = 413,000 New Brunswick New Construction = 183,000 Rehabilitation = 427,000 Nova Scotia New Construction = 66,000 Rehabilitation = 949,000 Tonnage Breakdown New Construction vs. Rehabilitation 1200000 Tonnage 1000000 800000 600000 400000 200000 0 Prince Edward Island Newfoundland Labrador New Brunswick Nova Scotia Average Asphalt Cost Per Tonne Placed Asphalt Pavement Average Cost Per Tonne $80 $75 $70 $65 $60 $55 $50 $45 $40 Prince Edward Island Newfoundland Labrador New Brunswick Nova Scotia 2006 Budgets Capitol vs. Paving Prince Edward Island 2006 Capitol Budget vs. Paving Allocation Newfoundland Total Capitol Budget = $20m Paving Operations = $10.5m Total Capitol Budget = $95m Paving Operations = $70 New Brunswick $250 Total Capitol Budget = $243m Paving Operations = $90m $200 (Millions) $150 $100 $50 $0 Nova Scotia Total Capitol Budget = $237m Paving Operations = $186m Prince Edward Island Newfoundland Labrador New Brunswick Nova Scotia The Move Towards Performance Based End Product Specifications Percent Performance Graded Specifications vs. Method Specification Projects 100 90 80 70 60 50 40 30 20 10 0 Prince Edward Island Newfoundland Labrador New Brunswick Nova Scotia Overview of PEI Operations Maintenance challenges related to clay rich sub-grade conditions. Asphalt aggregate dependent upon offshore supply from NS,NB and NL. Previously a pioneer in the use of soil cement in road construction. Marshall design method used with no immediate plans to change. Standard Marshall mixes are based on a19 mm aggregate base coarse and a 9.5 mm aggregate surface coarse gradation. Typically specify PG 58-28 asphalt cement. Very limited use of polymer modified asphalt cement. Overview of NL Operations Marshall design method utilized with no current plans to move toward other pavement design methods. PG 58-28 performance graded asphalt cement used on all mixes. 19mm base mixes and 12.5mm surface coarse mixes typically used Utilizing “performance based” price adjustments for smoothness. Due to geographic diversity mix challenges exist due to the wide variety and quality of aggregate types. Aggregate breakdown and stripping mixes are problems. Liquid anti-strip agents commonly used. NL specifications used to allow use of OM (Other Material) which was “just about anything you had” Overview of NB Operations Most surface coarse mixes designed to a 9.5mm Nominal Superpave gradation. Superpave design method utilized in formulization of surface coarse mixes. PG 58-28 asphalt binder typically used for new construction. PG 64-28 or PG 70-28 used for some highly trafficked climbing lanes. Additional $3.00/tonne paid for use of transfer vehicle. “High Speed” laser road profilers widely utilized to determine smoothness. NB central laboratory is fully AASHTO certified. NB placed the first Stone Mastic asphalt pavement sections in Atlantic Canada. Conducted a number of “Cold In-Place Recycle” projects over the past 2 years.. Overview of NS Operations Marshall design method utilized with 19mm, 12.5mm and 9.5mm mixes specified. PG 58-28 binder used for typical paving operations. PG 64-28 used on high traffic passing lanes or ramps. Successful wide spread adoption of performance based “End Product Specifications”. Development of Consultant based AASHTO certified Quality Assurance program. Conducted AASHTO certified PG Binder testing for past five years. Material transfer vehicles commonly used to minimize mix segregation and improve ride quality. Overview of NS Operations Completion of a “Rigid vs. Flexible Pavement” provincial wide feasibility study. Development of a “Sustainable Green Paving Practice” study for the Nova Scotia Department of Energy comparing traditional and recycle paving methodologies relative to typical “life cycle costs” plus “potential carbon credit” generation through measured hydrocarbon emission reduction. Ongoing development and implementation of a performance based specification for “Cold In Place Recycling”. NSTPW have commissioned over 30 projects using both “partial” and “full depth” construction methods utilized both emulsified and foamed asphalt binder. Where Are We Going? Prince Edward Island Continuation with existing program structure. Some additional use of Polymer Modified Asphalt Mixes in high traffic areas. Newfoundland / Labrador Continuation with Marshall Design method. Expanded use of asphalt ignition ovens for asphalt cement extractions. Contractor is responsible for the purchase and maintenance of the equipment. Smoothness specification being challenged by contractors. Where Are We Going? New Brunswick Widespread adoption of Superpave mixes. More “Stone Mastic” test sections in heavily trafficked areas.. Interest in “Warm Asphalt” Pavements application. Continued use of “Cold In-Place” recycle methodologies.. Nova Scotia Continued use of AASHTO certified consultants to provide Quality Assurance testing services. Consideration to moving to Superpave design method. Continuation with “Cold In-Place” recycle rehabilitation using both Full and Partial depth applications. Development of a new smoothness specification for asphalt pavements. Interest in “Warm Pavement Technology” Adoption of “High Speed laser road profilers”. Shadow testing in 2007. Development of a formal Provincial Pavement Management Program. Thank you for your attention. Questions? 2006 CUPGA Meeting. Charlottetown, PEI