Safe Handling of

Compressed Gases

Reasons for a Safety Seminar

• To heighten the awareness of the

dangers associated with compressed

gases

• To encourage safe operating practices

in their everyday use

• To help ensure the right equipment is

used for your application

Definition

Compressed Gas

Any material or mixture

with an in-container

pressure exceeding 40 psia

at 70F, or a pressure

exceeding 104 psia at

130F, or any liquid

flammable material having

a vapor pressure exceeding

40 psia at 100F [sec.

173.300(a)].

The Gas: Rule #1!

Know the properties of the materials involved

Gases may be:

• Under high pressure

• Toxic

• Corrosive

• Flammable

• Pyrophoric

• Oxidizers

High Pressure Gas

• Can cause equip. to fail with explosive force

• When released can diffuse into the atmosphere

very rapidly, and an entire room may be

thoroughly contaminated within seconds!

• A common 9” dia X 52” high cylinder

pressurized to 2000 psi has the stored energy

equivalent to one pound of dynamite!

• Cylinders are commonly filled to standard

pressures of 2000 psi, 2490 psi, 3500 psi and

6000 psi.

Toxic Gases

• Have the ability to cause injury or

death when ingested or absorbed by

the skin

• Examples include Ammonia, Vinyl

Chloride and Phosgene

Corrosive Gases

• Will attack and damage human tissue

• Will have an adverse effect on

improper materials of construction

• Examples of corrosive materials are

Hydrogen Chloride, Hydrogen

Fluoride

Flammable & Pyrophoric Gases

• Flammable gases easily catch fire and burn

rapidly in air

• Examples of flammable gases are Acetylene,

Hydrogen, Propane, and Propylene

• Pyrophoric gases spontaneously ignite and

burn when exposed to the atmosphere

• Silane is a pyrophoric gas which is commonly

used in the electronics industry

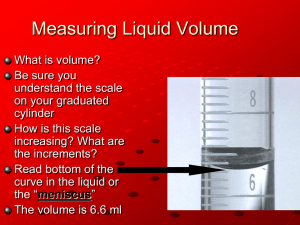

Liquefied Compressed Gases

• Contents of a

liquefied compressed

gas cannot be

determined by the

pressure in the

cylinder, and a

cylinder scale must

be used

Shipping Regulations

Dept. of Transport (D.O.T.) regulations specify the familiar

diamond shaped tag that must be affixed to each cylinder being

shipped

Material Safety Data Sheets

• Required in workplace

• Substance fact sheet listing

characteristics, hazards and as

much detail as possible

concerning the particular gas

SECTION 4

FIRST AID MEASURES

INHALATION: If adverse effects occur, remove to

uncontaminated area. Give artificial respiration if

not breathing. If breathing is difficult, oxygen should

be administered by qualified personnel. Get

immediate medical attention.

SKIN CONTACT: If frostbite or freezing occur,

immediately flush with plenty of lukewarm water

(105-115 F; 41-46 C).

Threshold Limit Values (TLV’s)

• Time Weighted Average (TWA)

- Average 8 hour exposure, 5 days a week

• Short Term Exposure Limit (STEL)

- 15 minutes, 4 times a day

• Immediately Dangerous to Life and Health

(IDLH)

Personal & Fixed Gas Monitors

Compressed Gas Cylinders

• Come in many shapes and

sizes

• Commonly constructed of

Carbon Steel or Aluminum

• Standard size 1A cylinder

pressurized to 2200 psig holds

approx. 225 ft3 of gas in an

internal volume of 1 ½ ft3!

Cylinder Identification

And Markings

1

Specification number consists of three sections.

• DOT- signifies that the cylinder

conforms to Department of

Transportation (DOT) specification.

• 3AA - specifies type and material of

cylinder construction.

• 2265 - indicates service pressure

for which the cylinder is designed

at 70F.

Cylinder Identification

And Markings

2

Cylinder serial number

(Matheson Tri-Gas number)

Cylinder Identification

And Markings

3

Date of initial hydrostatic

testing

Cylinder Identification

And Markings

4

Original inspector's insignia

Cylinder Retest Schedule

Specification under which

cylinder was made

Minimum

retest pressure (psi)

Retest

period (years

DOT-3

3000 psi

5

3D

5/3 times service pressure

5

4

700 psi

10

DOT-9

400 psi (maximum 600 psi)

5

26 for filling at over 450 psi

5/3 times service pressure

5

33

800 psi

5

CGA Connections

• Compressed Gas Assoc.

• Reasons for CGA standards

• CGA gaskets/washers

• Restricted flow orifices

CGA Connections

Matheson Tri-Gas

Product Safety & Code Compliance

Primary Governing Bodies / Safety Codes

Compressed Gas Association (CGA)

Semiconductor Equipment & Materials International (SEMI)

US Environmental Protection Agency (EPA)

Uniform Fire Code / Local City Regulatory Committee (UFC)

Uniform Building Code (UBC) / BOCA

National Fire Prevention Code (NFPC)

International Conference of Building Officials (IBOC)

Toxic Gas Ordinance (TGO)

Cylinder Handling and

Transportation

• Upon receipt, visually inspect the cylinders for obvious

defects such as dents, large amounts of rust and missing

or loose safety caps.

• Cylinders shouldn’t be accepted unless identified with

the appropriate labeling, and all them agree with one

another!

• Use a cylinder cart and secure the cylinders with a chain

when moving.

• Don’t use the protective valve caps for moving or lifting

the cylinders.

Cylinder Handling and

Transportation

• Don’t drop a cylinder, permit them to strike each other

violently or be handled roughly.

• Unless cylinders are secured, regulators should be

removed, valves closed and protective caps in place

before cylinders are moved.

• Rolling cylinders in a vertical position on the bottom

edge is to be avoided as much as possible. Gas cylinders

must never be dragged or rolled in the horizontal

position.

Cylinder Storage

• Double restrain cylinders

with non-combustible

material (i.e., chain)

• Label Full versus Empty

• Signs for hazardous gases

• Keep away from traffic areas

• Store in fire resistant, well

ventilated, dry areas

Cylinder Storage

•

•

•

•

Keep away from flames or sparks

Keep caps on when not in use

Store in areas <125°F

Keep oxidizers 20 ft. from

flammables

• Corrosives should be stored less than

6 months

Pressure Regulators

and How They Work

Single Stage Regulator

Outlet

gauge

Inlet

gauge

Temporary

shut-off

valve

CGA inlet

connection

P/A knob

Single Stage Regulator

Reduces the inlet supply

pressure in “one step”,

from the inlet supply

pressure to the final outlet

pressure

Single Stage Regulator

Applications:

• Intermittent use - where a

sample of gas is required

from a cylinder

• Where pressure rise in a set

delivery pressure is not

critical

• As a line regulator where

there is a second pressure

regulator at the gas supply

source

Single Stage Regulator

Characteristics:

Rule of thumb: for every

100 psig drop on the inlet

pressure, there will be 1

psig rise on the outlet

working pressure

Two-Stage Regulator

Reduces the pressure in

“two steps” from a high

pressure inlet source, to the

final outlet working

pressure

Two-Stage Regulator

Characteristics:

• Delivery “set pressure”

remains constant as the inlet

supply pressure decays

• Becomes a single stage regulator

when the source supply pressure

becomes less than the set pressure

of the first stage (~300 psig)

• Can be supplied with an inter-stage

relief valve as insurance in the

event of first stage seat failure

Two-Stage Regulator

Applications:

• Recommended for continuous

use applications, such as carrier

gas supply to GC’s or other

analytical instruments, where

it is critical that a constant

delivery set pressure be

maintained

Regulator Installation

• Do not use CGA adaptors or change

CGA connections on regulators for a

different gas service – unless work is

done by qualified personnel!

• Always ensure there are no nicks and

scratches on regulator CGA

connections

• Never use Teflon tape to achieve a

proper seal

• Always leak check connections using a

soap bubble solution or electronic leak

detector

Regulator Operation

• Always ensure the P/A knob is backed off

counterclockwise to ensure there is no load on the

regulator load spring – prior to opening the cyl valve!

• Never open a cylinder valve all the way. 1 ½ to 2 turns is

usually sufficient

• Always stand with the cylinder valve between you and

the regulator when opening the cylinder valve and/or

adjusting pressure on the regulator

• Do not use the temporary shut-off valve to turn off gas

flow if the shut-off duration will be longer than 20 min.

• Use cross or T-purge assemblies if regulators are to be

used for toxic or corrosive gases!

Regulator Failures

• 95% of regulator failures are due to seat

failures, caused by:

– Corrosion buildup on the seat

– Contamination (dirt, metal filings, Teflon tape)

that scores the seat at a high velocity

Set pressure creep on the delivery pressure

gauge indicates a seat failure!

Regulator Failures

• A Pressure gauge that will not read zero

indicates the bourdon tube has been

damaged and the gauge must be replaced!

• Gas leaking through the bonnet assembly of

the regulator indicates a diaphragm failure

(Typically caused by failure to ensure the

regulator is shut off prior to installing it on

a new cylinder)

Safety Devices:

• Check valve: prevents reverse

gas flow

• Flash Arrestor: prevents

ignition source from reaching

regulator and cylinder for

flammables

• Excess Flow Valve: restricts

flow in the event of a gas line

break

Things Not To Do!

• Never roll a cylinder to move it.

• Never carry a cylinder by the valve.

• Never leave a cylinder unsecured.

• Never force improper attachments

on to the wrong cylinder.

• Never grease or oil the regulator, valve

or fittings of an oxygen cylinder.

• Never refill a cylinder.

• Never attempt to mix gases in a cylinder.

Safe Gas Usage

• Compressed gases serve laboratories and industrial

plants in many ways, but the cylinders and gases present

a number of hazards.

• “Treat all gas cylinders, full or empty, as objects that

have a very real potential to injure you severely.”

Consider

Reduction/elimination of gas cyl’s in the lab

• Through a centralized gas distribution system

• Gas generators for H2, N2 or Zero Air

Emergency Plan

• Every location where compressed gases are

handled should have a written emergency

plan covering steps to be taken in the event

of an accidental release of gas

• This plan should consider the nature of the

gases being handled, that is their chemical

and physical properties

Plan Elements

At a minimum, the plan should specify the

following :

• Alarm System & Evacuation Procedure

• Response Personnel

• Emergency Equipment

• Containment or disposal methods

Additional Safety Information

Additional Safety Information

Safety is our First Priority

All rights reserved. No part of this presentation may be reproduced or used in any form whatsoever without the express written

permission of Matheson Tri-Gas, Inc.; except in the case of brief quotations embodied in critical articles and reviews. The

information contained here is for the personal use of the reader and may not be incorporated in publications, databases, or

software programs without the written consent of Matheson Tri-Gas, Inc.

This publication is intended to provide accurate information in regard to the subject matter covered and has been obtained from

sources believed to be reliable. Of necessity the information is abbreviated and other information, training and/or education is

required of the user of this information. Accordingly, Matheson Tri-Gas, Inc. makes no warrantees, guarantees, or

representations of any kind or nature with respect to the information published herein, either express or implied, and whether

arising by law or otherwise, including but not limited to any implied warranty of merchantability or fitness for any particular

purpose, and shall not be responsible for any errors, omissions, or damages arising out of use of this information. Matheson shall

in no event be liable for any personal injuries, property or other damages of any nature whatsoever, whether special, indirect,

consequential or compensatory, directly or indirectly resulting from the publication of, or reliance upon the information.