MP - Instrumatic

advertisement

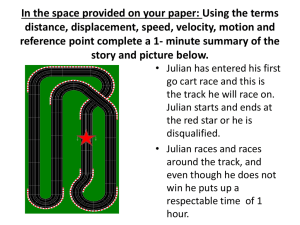

MP Series Multipulse Positive Displacement Flowmeters Multipulse Positive Displacement Flowmeters Quality & Simplicity in Flow Measurement Innovative Technologies, Creative Solutions MP Multipulse Positive Displacement Flowmeters Introduction Multipulse Positive Displacement Flowmeters provide: Pulse or LCD Display High levels of accuracy and repeatability. Wide range of liquids from low viscosity solvents and chemicals to viscous oils, greases and food bases. Low pressure drop allows for economical pump selection or gravity flow applications. MP Multipulse Positive Displacement Flowmeters Principal of Operation Principal of Operation The MP series uses the oscillating - piston principle where the passage of liquid causes a piston to oscillate smoothly in a circular motion within the measuring chamber. Each piston cycle passes a known volume of liquid from the inlet to the outlet port, magnets in the piston activate the reed switch and the solid state sensor to provide pulse outputs for remote flow, measurement and process control. MP Multipulse Positive Displacement Flowmeters Principal of Operation The diagram below shows the transition of fluid from the Inlet Port through the Measuring Chamber and then out the Outlet Port. MP Principal of Operation MP Principal of Operation MP Multipulse Positive Displacement Flowmeters Features/Benefits Low Number of Parts IP67/ Nema 4x Flameproof Terminal Cover Pulse output board with both hall effect and reed switch (intrinsically safe with approved barrier) Body and manifold have no stagnate chambers Free rotating piston is the only moving part Partition MP Multipulse Positive OutputsDisplacement Flowmeters Two Pulse Outputs Reed Switch Output - Provides a voltage free contact closure. The reed switch is classed as a 'simple device' and can be used in hazardous areas when connected via an approved intrinsically safe barrier. Square Wave Output - An open collector pulse output produced by a solid state hall effect device. This 3 wire device requires 5-24vdc excitation voltage and produces a high resolution square wave output. MP Multipulse Positive FeaturesDisplacement Flowmeters Multipulse Features 316L stainless steel, aluminium or UPVC construction ( selected Sizes ) Accuracy +/- 0.5% of rate Has no stagnate chambers or cavities Measures low and high viscosity liquids to 1,000,000 cp No requirement for flow conditioning Adaptable to hygienic installations High Pressure models to 5,150 psi (350 bar) Flameproof or intrinsically safe electronics (optional) Insensitive to mounting orientation. MP Multipulse Positive Flowmeters Stainless Steel Displacement Models Sizes: 1/2” (15mm) 1” (25mm) 1 1/2” (40mm) 2” (50mm) Material: 316LST.ST body and Manifold Peek or carbon piston and bearing special materials consult factory Flow Ranges: 0.04 - 2.2 GPM 0.5 - 13.2 GPM 1.1 - 35 GPM 3.1 - 88 GPM (.17-8.3 LPM) (2 - 50 LPM) (4.2 - 133.3 LPM) (11.7-333.3 LPM) MP Multipulse Positive Flowmeters Stainless Steel Displacement Models Process Connections: Threaded BSPP/NPT female thread flanged, ANSI/DIN standards Pressure Rating: 740 - 5,150 psi (50-350 Bar) Temperature Rating: -40ºF to +300ºF (-40ºC to +150ºC) for higher temperature contact factory Multipulse Outputs: Reed switch, NPN open Collector output standard MP Multipulse Positive Flowmeters Stainless Steel Displacement Models Options: - Explosion Proof or Intrinsically safe operation - Integral or remote high speed preset batch controller - Integral or remote battery power flow rate totaliser with scaled pulse output, analog and flow alarm outputs. Applications: Chemical and allied products, pharmaceuticals, petroleum, deionised water, container filling machines, fuel additives, asphalt, paint, synthetic rubber, latex, detergent and soap, pigments. MP Multipulse Positive Displacement Flowmeters Aluminum Models Sizes: 1/2” (15mm) 1” (25mm) 1 1/2” (40mm) 2” (50mm) Material: Aluminium body and Manifold Peek or carbon piston and bearing special materials consult factory Flow Ranges: 0.04 - 2.2 GPM 0.5 - 13.2 GPM 1.1 - 35 GPM 3.1 - 88 GPM (.17-8.3 LPM) (2 - 50 LPM) (4.2 - 133.3 LPM) (11.7-333.3 LPM) MP Multipulse Positive Displacement Flowmeters Aluminum Models Process Connections: Threaded BSPP/NPT female thread flanged, ANSI/DIN standards (lap joint flanges) Pressure Rating: 300 to 1,200 psi (20-80 Bar) Temperature Rating: -40ºF to +300ºF (-40ºC to +150ºC) for higher temperature contact factory Multipulse Outputs: Reed switch, NPN open Collector output standard MP Multipulse Positive Displacement Flowmeters Aluminum Models Options: - Explosion Proof or Intrinsically safe operation - Integral / remote RT rate totalizer. - Integral or remote battery power flow rate totaliser with scaled pulse output, analog and flow alarm outputs. Applications: Metering petroleum products, diesel, fuel oil, hydraulic oil, kerosene, LPG, gasoline, alcohol, solvents, lacquers and selected chemicals. MP Multipulse Positive Displacement Flowmeters High Pressure Stainless Steel Models Process Connections: Threaded BSPP/NPT female thread flanged, ANSI/DIN standards specials consult factory Pressure Rating: Up to 5,150 psi maximum (350 bar) Temperature Rating: -40ºF to +250ºF (-40ºC to +120ºC) for higher temperature contact factory Multipulse Outputs: Reed switch, NPN open Collector output standard MP Multipulse Positive Displacement Flowmeters High Pressure Stainless Steel Models Sizes: 1/2” (15mm) 1” (25mm) 1 1/2” (40mm) 2” (50mm) Material: 316LST.ST and Manifold Peek or carbon piston and bearing Flow Ranges: 0.2-10.0 LPM 2 - 50 LPM 4 - 140 LPM 12-330 LPM Options: - Explosion Proof or Intrinsically safe operation - Integral or remote high speed preset batch controller - Integral or remote battery power flow rate totaliser with scaled pulse output, analog and flow alarm outputs. Applications: Hydraulics, lube oils, mercaptan, petroleum, deionised water, resins, Mek, Ethylene oxide, oil and gas industry, chemical injection. MP Multipulse Positive Displacement Flowmeters SAP Models Size: 20mm Pressure Rating: 60 psi (4 bar) Material: UPVC body and Manifold Carbon filled teflon piston and bearing (uv stabilised PVC) special material consult factory Temperature Rating: 60 deg C Flow Ranges: 2.0 - 50.0 LPM Process Connections: Threaded BSPP/NPT female thread Multipulse Outputs: Reed switch, NPN open Collector output standard Options: - Intrinsically safe operation - Remote high speed preset batch controller - Remote battery power flow rate totaliser with scaled pulse output, analog and flow alarm outputs. MP Multipulse Positive Displacement Flowmeters SAP Models Applications: MP020P flow meter manufactured from UV stabilized PVC (UPVC) is ideally suited for special applications associated with corrosive fluid such as sodium hypochlorite, acids, photographic solutions or any chemical compatible with UPVC. The MP020P has flow range of 2 – 50 LPM and provides and economical solution for those difficult fluids compared to more expensive magnetic flow meters or Coriollis mass flow meters manufactured from more exotic materials. MP Multipulse Positive Displacement Hygienic Stainless Steel ModelsFlowmeters Process Connections: Threaded BSPP/NPT female thread Tri-clamp hygienic fittings BS/DIN standards (or equivalent) Pressure Rating: 750 - 1,500 psi (50-100 bar) Temperature Rating: -40ºF to +300ºF (-40ºC to +150ºC) for higher temperature contact factory Multipulse Outputs: Reed switch, NPN open Collector output standard MP Multipulse Positive Displacement Hygienic Stainless Steel ModelsFlowmeters Sizes: 1/2” (15mm) 1” (25mm) 1 1/2” (40mm) 2” (50mm) Material: 316LST.ST body and Manifold Peek or carbon piston and bearing Flow Ranges: 0.2 - 10LPM 2 - 50 LPM 4- 140 LPM 12 – 330 LPM Options: - Explosion Proof or Intrinsically safe operation - Integral or remote high speed preset batch controller - Integral or remote battery power flow rate totaliser with scaled pulse output, analog and flow alarm outputs. Applications: Pharmaceuticals, cosmetics, deionised water, food and beverage, container filing machines, yeast, confectionery, molasses, liquid sugar, mayonnaise, chocolate, dairy products. MP Model Prefix Body Material Nominal Flow Spans* Accuracy Repeatability Maximum Pressure Temperature Range Piston Material Multipulse Positive Flowmeters Specifications Displacement - 15mm MP015S MP015A MP015H 316L stainless steel Aluminium 316L stainless steel 10 to 100 / 100 to 300 & 300 to 600 lph (2.6 to 160 USgal/hr) *Turndown (flow range) varies in accordance with effective viscosity of metered liquid +1% of rate within nominal spans Accuracy over the full flow range is improved to within + /-0.5% when utilising the linearisation feature of the optional Trimec RT flow rate totaliser Typically +0.1% under steady flow conditions 100 Bar (1500 psi) 30 Bar (440 psi) 350 Bar (5150 psi) Three ranges covering operation from -40 to 150o C (-40 to 300o F) limited to 80oC (176oF) with integral electronic register Carbon filled teflon – option PEEK MP Multipulse Positive Flowmeters Specifications Displacement - 15mm MP015S Model Prefix O-ring Material MP015H viton, EPR (EPDM), teflon encapsulated viton or nitrile (Buna-N) Reed Switch Output 30vdc maximum voltage, 20mA maximum current Pulse resolution: 200 pulses / litre (760 pulses / US gallon) Open Collector Output 5 to 24vdc (25vdc maximum) 3 wire NPN (sinking current) 20mA maximum current - 1000 metres (3300 ft) maximum transmission Pulse resolution: nominally 400 pulses / litre (1520 pulses / US gallon) Electrical Connection Process Connections MP015A M20 x 1.5 or 1/2" NPT female entries 1 1 /2" BSPP or NPT /2" ANSI 150/300RF flanges 1 /2" BSPP or NPT (Lap Joint flanges on request) 1 /2" BSPP or NPT (others on request) DN15 PN16 - 40 flanges triclamp hygienic (others on request) Environmental Protection IP66 (Nema 4), optionally flameproof to Exd IIB T4 (Class 1, Groups C & D) Recommended Filtering 150 microns (100 mesh) MP Model Prefix Body Material Nominal Flow Range* Accuracy Repeatability Maximum Pressure Temperature Range Piston Material Multipulse Positive Flowmeters Specifications Displacement - 25mm MP025S MP025A MP025H 316L stainless steel Aluminium 316L stainless steel 120 to 3000 lph (0.5 to 13.2 USGPM) *Turndown (flow range) varies in accordance with effective viscosity of metered liquid +0.5% of rate Accuracy and turndown can be improved utilising the linearisation feature of the optional Trimec RT flow rate totaliser Typically +0.03% under steady flow conditions 100 Bar (1500 psi) 80 Bar (1200 psi) 350 Bar (5150 psi) Three ranges covering operation from -40 to 150o C (-40 to 300o F) limited to 80oC (176oF) with integral electronic register Carbon filled teflon – option PEEK for special materials - consult factory MP Multipulse Positive Flowmeters Specifications Displacement - 25mm Model Prefix O-ring Material Reed Switch Output Open Collector Output MP025S MP025H viton, EPR (EPDM), teflon encapsulated viton or nitrile (Buna-N) 30vdc maximum voltage, 20mA maximum current Pulse resolution: nominally 20 pulses / litre (76 pulses / US gallon) 5 to 24vdc (25vdc maximum) 3 wire NPN (sinking current) 20mA maximum current - 1000 metres (3300 ft) maximum transmission Pulse resolution: nominally 100 pulses / litre (380 pulses / US gallon) Electrical Connection Process Connections MP025A M20 x 1.5 or 1/2" NPT female entries 1" BSPP or NPT 1" ANSI 150/300RF flanges 1" BSPP or NPT (Lap Joint flanges on request) 1" BSPP or NPT (others on request) DN25 PN16 - 40 flanges triclamp hygienic (others on request) Environmental Protection IP66 (Nema 4), optionally flameproof to Exd IIB T4 (Class 1, Groups C & D) Recommended Filtering 250 microns (50 mesh) MP Model Prefix Body Material Nominal Flow Range* Accuracy Repeatability Maximum Pressure Temperature Range Piston Material Multipulse Positive Flowmeters Specifications Displacement - 40mm MP040S MP040A MP040H 316L stainless steel Aluminium 316L stainless steel 250 to 8000 lph (1.1 to 35 USGPM) *Turndown (flow range) varies in accordance with effective viscosity of metered liquid +0.5% of rate Accuracy and turndown can be improved utilising the linearisation feature of the optional Trimec RT flow rate totaliser Typically +0.03% under steady flow conditions 100 Bar (1500 psi) 30 Bar (440 psi) 350 Bar (5150 psi) Three ranges covering operation from -40 to 150o C (-40 to 300o F) limited to 80oC (176oF) with integral electronic register Carbon filled teflon – option PEEK For special materials - consult factory MP Multipulse Positive Flowmeters Specifications Displacement - 40mm MP040S Model Prefix O-ring Material MP040H viton, EPR (EPDM), teflon encapsulated viton or nitrile (Buna-N) Reed Switch Output 30vdc maximum voltage, 20mA maximum current Pulse resolution: nominally 7.3 pulses / litre (28 pulses / US gallon) Open Collector Output 5 to 24vdc (25vdc maximum) 3 wire NPN (sinking current) 20mA maximum current - 1000 metres (3300 ft) maximum transmission Pulse resolution: nominally 44 pulses / litre (167 pulses / US gallon) Electrical Connection Process Connections MP040A M20 x 1.5 or 1/2" NPT female entries 11/2" BSPP or NPT 1 /2" ANSI 150/300RF flanges 1 11/2" BSPP or NPT (Lap Joint flanges on request) 11/2" BSPP or NPT (others on request) DN40 PN16 - 40 flanges triclamp hygienic (others on request) Environmental Protection IP66 (Nema 4), optionally flameproof to Exd IIB T4 (Class 1, Groups C & D) Recommended Filtering 250 microns (50 mesh) MP Model Prefix Body Material Nominal Flow Range* Accuracy Repeatability Maximum Pressure Temperature Range Piston Material Multipulse Positive Flowmeters Specifications Displacement - 50mm MP050S MP050A MP050H 316L stainless steel Aluminium 316L stainless steel 700 to 20,000 lph (3 to 88 USGPM) *Turndown (flow range) varies in accordance with effective viscosity of metered liquid +0.5% of rate Accuracy and turndown can be improved utilising the linearisation feature of the Trimec RT flow rate totaliser Typically +0.03% under steady flow conditions 38 Bar (560 psi) 20 Bar (300 psi) 100 Bar (1500 psi) Three ranges covering operations from -40 to 150o C (-40 to 300o F) limited to 80oC (176oF) with integral electronic register carbon filled teflon – option PEEK For special materials - consult factory MP Multipulse Positive Flowmeters Specifications Displacement - 50mm Model Prefix O-ring Material Reed Switch Output Open Collector Output MP050S MP050H viton, EPR (EPDM), teflon encapsulated viton or nitrile (Buna-N) 30vdc maximum voltage, 20mA maximum current Pulse resolution: nominally 2.5 pulses / litre (9.5 pulses / US gallon) 5 to 24vdc (25vdc maximum) 3 wire NPN (sinking current) 20mA maximum current - 1000 metres (3300 ft) maximum transmission Pulse resolution: nominally 20 pulses / litre (76 pulses / US gallon) Electrical Connection Process Connections MP050A M20 x 1.5 or 1/2" NPT female entries 2" BSPP or NPT 2" ANSI 150/300RF flanges 2" BSPP or NPT (Lap Joint flanges on request) 2" BSPP or NPT (others on request) DN50 PN16 - 40 flanges triclamp hygienic (others on request) Environmental Protection IP66 (Nema 4), optionally flameproof to Exd IIB T4 (Class 1, Groups C & D) Recommended Filtering 500 microns (25 mesh) MP Multipulse Positive Displacement Flowmeters Key Selling Highlights The product concept has advantages over conventional positive displacement flow meters. Up to 70% cost saving for an installation requiring a stainless steel flow meter. Has only one moving part giving extended troublefree working life. Installation flexibility in vertical or horizontal pipes, no need for straight pipes runs or conditioned flow. Has no stagnate chambers to accumulate contaminants or stale product. MP Key Selling Highlights No modifications are needed when measuring high viscosity liquids. Can be cleaned in place using chemicals or controlled steam pressure/temperature. Quick and easy to clean in place without the need for special tools. Extremely compact and comparatively light weight. Limited number of spare parts needed to support the product. MP Multipulse Positive Displacement Flowmeters Key Market Sales Areas Key Market Sales Areas The features of the Multipulse have broad appeal in all areas of industry and provide low cost of ownership and maintenance. Chemical manufacturers or handling - acids or solvents. Pharmaceutical's - medical and cosmetic liquids. Pet food manufacturers, stock feed and poultry plants injecting food supplements and colourings. Container filling machines and bottling equipment manufacturers. Industries requiring 'in-line cleaning' confectionery, food and drink manufacturing. Petroleum refineries, petroleum distribution, fuel additive injection systems, lube oil and grease dispensing. Hydraulics and hydraulic driven epoxy injection systems. Foam rubber manufacturers for injecting chemicals. Paper manufacturing and related printing ink applications. MP Chemicals Additives Resins Acids Alcohols Essences Edible Oils Flavourings Food Bases Perfumes Applications Adhesives Emulsions Insecticides Paints Inks Oils Fuels Grease Solvents Lubricants MP Multipulse Positive Displacement Flowmeters Application Multi Head Filling Machine MP Multipulse Positive Displacement Flowmeters Summary Trimec has achieved universal acceptance of its MP Series Positive Displacement Flowmeters, in a diversity of industrial flow measurement applications, as a result of innovative design concepts featured in its range of flow products. The meter capability has gained acceptance in the International Markets of the World, with established sales in Europe, Asia and now with entry into the United States market, Trimec is assured of being recognized as a leading manufacturer of quality flow measurement products.