Subpart K Electrical

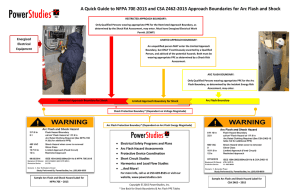

advertisement

Electrical These handouts and documents with attachments are not final, complete, or definitive instruments. This information is for guidance purposes only. You should independently verify and satisfy yourself as to its accuracy. The AHBSIF does not assume any liability for damages arising from the use of this information or exhibits and attachments thereto and renders no opinion that any of the terms, conditions, and/or cited federal standards in this document and the exhibits and attachments should be explicitly followed by the fund member. Seek specific guidance from the appropriate regulator (OSHA) or professional advisor. Serious Exposure Electrocution is one of the top four causes of construction fatalities Nearly half of those fatalities were the result of contact with overhead power lines OSHA is making an effort to focus more attention to these exposures Applicable Standards Electrical standards are among the most frequently cited by OSHA No Lock Out/Tag Out Improper Wiring Methods Inadequate Components and Equipment OSHA references the following for guidelines Electric Safety Requirements for Employee Workplaces and codes (NFPA 70E) Basic Terminology Amps – The amount of electricity flowing Volts – The force at which the power flows Ohms – A unit of electrical resistance Watts – A unit of electrical power Physical Effects Amps are the true measure of current absorbed, not volts We are good conductors, the human body is 70% water Involuntary muscle contraction is the reason we are affected Can’t let go of energized object Breathing is impaired Heart rhythm is disrupted Physical Effects 1 mA Barely perceptible 16 mA 20 mA Max current an average man can grasp and let go Paralysis of respiratory muscles 100 mA Ventricular fibrillation threshold 2 amps Cardiac standstill and internal organ damage 15 to 20 amps Current required to trip common household breaker Influencing Factors of a Shock Circumstances that affect the outcome of an electric shock; Circuit voltage The bodies external (skin) and internal resistance Total current flowing through the body Current path The duration of the shock Arc Flash The result of a rapid release of energy due to an arcing fault, air is the conductor. Arc faults are generally limited to systems where the voltage is in excess of 120 volts. Massive energy is discharged, vaporizing the copper and causing an explosion. Arcs can produce temperatures up to 35,000° F. Flash hazards can produce pressure waves, concentrated sound blasts, and release deadly shrapnel. Arc Flash Arc flash and blast hazards were not formally studied until the early 90’s Generally occur less frequently than electric shock NFPA 70E provides directives on reducing the occurrence and effects of arc flash NFPA 70E – Flash Protection Guidelines Compliance of NFPA 70E, Arc Flash Protection requires the following: Justification for live work Work Permits when applicable Approach Boundaries Approach Boundaries Limited Approach Boundary Electric Panel Entered only by a Qualified Person or unqualified person escorted by QP Restricted Approach Boundary F r o n t Entered only by a Qualified Person required to use shock protection techniques and PPE Prohibited Approach Boundary Entered only by a Qualified Person requiring same protection as if in direct contact with live part Flash Protection Boundary Electric Panel F r o n t The Flash Protection Boundary is the linear distance to prevent any more than 2nd degree burns from a potential arc flash Distance is usually four feet Distances for all shock protection boundaries can referenced in Table 130.2(C) of NFPA 70E What kind of PPE is necessary? The level of personal protective equipment necessary for the exposure can be determined one of two ways: Shock Hazard Analysis - OR Flash Hazard Analysis Shock Hazard Analysis Must determine the following: The operating voltage of the system Shock protection boundaries Required personal protective equipment [ reference Tables 130.7(C)(9)(a) and 130.7(C)(10) NFPA 70E ] Flash Hazard Analysis Must determine the following: The flash protection boundary The incident energy exposure level Protective clothing and PPE Flash Hazard Analysis The flash protection boundary Use the flash protection boundary formula OR default 130.3(A) The incident energy exposure level distance between workers face and chest from the arc source OR 130.7(C)(9) and 130.7(C)(10) Protective clothing and PPE Once incident energy is determined, safety equipment has to have a rating greater than or equal to the incident energy available Personal Protective Clothing, NFPA 70E Category Cal/cm2 0 1 2 3 4 1.2 Clothing Untreated Cotton 5 Flame retardant (FR) shirt and FR pants 8 Cotton underwear FR shirt and FR pants 25 Cotton underwear FR shirt, FR pants and FR coveralls 40 Cotton underwear FR shirt, FR pants and double layer switching coat and pants Employer Responsibilities Equipment must be: Free from recognized hazards Suitable and identified through listing, labeling, or certification of purpose. Designed with adequate mechanical strength and durability Other items for consideration Electrical insulation Heating effects /conditions of use Arcing effects Use classifications Guarding Live parts of electrical equipment operating at 50 volts or more must be guarded against accidental contact. Means of acceptable guarding include: Isolation in a cabinet, room, or vault accessible only by qualified persons Use of partitions or screens to exclude unqualified persons Elevation of eight feet or more above the floor Electric installations over 600 require special protection metal-enclosed Vault controlled by lock Lock Out / Tag Out LOTO written program Components Documented energy control procedures Employee Training program Inspection program Lock Out / Tag Out Purpose is to draw attention to and disable a live energy source during service and repair work. Lock Out physically disables the energy source, Tag Out provides a warning only Only the employee who placed the lock or tag may remove it! Safe Power Shutdown - 5 Steps Preparation and Notification– Understanding energy source and alerting all affected employees Shutdown – De-energizing procedure Isolation – Properly locking all power sources Lock & Tag Application Color coding for different trades Employee assigned locks Photo tags, helps locate employee, makes association Control and Verification– Control stored and residual energy with locks in place Re-energizing - 3 Steps Inspection – checking the work area and surrounding machinery and for employees Notification – Make notice to all affected employees as to what will be re-energized Removal of Tags and Locks Tags and Locks Tags and Locks must be: Durable – resist conditions of environment Standardized – color code and format Substantial – strong enough to minimize false removal Identifiable – clear message, know who it is protecting Extension Cords Cords with missing ground prongs, insulation breeches, crimping or crushing, must be removed from service. Splicing is prohibited, but new connectors are acceptable When unplugging, pull the plug, never tug on the cord If a cord must cross a vehicle pathway it must be protected OSHA considers an extension cord temporary power, no matter the power source! Service Ratings Hard Service (types S, ST, SO, STO) Junior Hard Service (types SJ, SJO, SJT, SJTO) Home use, small appliance (type SP) Ground Fault Circuit Interrupters Ground Fault Circuit Interrupters (GFCI’s) sense changes in current (5 milliamps) and stop energy flow. Devices stop current in 1/40 of a second Never bypass any protective system or device designed to keep you from contact with electrical current. All temporary power sources must have GFCI protection either at main box, extension cord, or tool. Portable Generators Never use a generator indoors or in an attached garage. Use extension cords with adequate duty ratings. To prevent electrical shock, make sure your generator is properly grounded. Do not store fuel indoors or try to refuel a generator while it's running. Turn off all equipment powered by the generator before shutting it down. Other Considerations Environmental Deterioration of Equipment Unless specified for use in such an environment, no conductors or equipment should be exposed to; Damp or wet locations Gases, fumes, vapors, liquids, or deteriorating agents Excessive Temperatures other Safe Work Practices Always check the location of overhead power lines (most common source of electrocution) Stay away from energized power circuits Locate all utilities prior to digging or jack hammering Protect electrical equipment in passageways from contact Keep walking and working surfaces free of electrical cords as much as possible Always de-energize equipment before repair or service work Electrical Checklist Extension cords: - No crimping or crushing - No missing insulation - No signs of stress at plug All extension cords out of high traffic areas: - Road ways (protective cover) - Driveways - Hallway, entrance, stairwell Lock Out / Tag Out plan for all maintenance operations Equipment rated for duty and environment Proper PPE when necessary GFCI protection at box, cord, or tool Awareness of all overhead power lines All tools double insulated Pre-job identification of all underground utilities Generators must have earth ground