Ocean General Presentation

advertisement

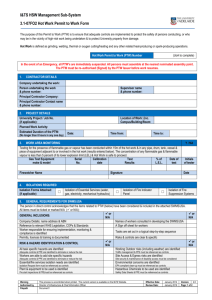

Diamond Offshore Drilling Inc OCEAN GENERAL - HSE Overview Jack Hird - Operations Manager Alif Abdullah- HSE Supervisor Diamond’s Mission Statement Diamond Offshore Drilling is committed to operate at the highest possible level of operational integrity and quality, while emphasizing exemplary performance in the areas of health, safety, environmental protection, and regulatory compliance. Diamond Offshore's mission is to exceed Customer expectations and continually set the standard of excellence as we assist our Customers in their worldwide efforts to discover and produce offshore petroleum resources. Safety and Health Policy Statement • ALL Injuries and Occupational Illnesses can be Prevented • Safety is Everyone’s Responsibility • People are the Most Critical Element in the Success of a Health and Safety Program • Working Safely is a Condition of Employment • Management is Directly Accountable for Preventing Injuries and Occupational Illnesses Environmental Policy Statement • Adhere to the host country rules and regulation • Protect the environment • Zero discharge for hazardous waste overboard • Use a environmental friendly products. Other Policies STOP WORK POLICY The responsibility and authority to initiate a Stop Work IMMEDIATELY, without fear of reprisal, when the employee believes a situation exists which places himself/herself, a coworker(s), or the environment in danger or at risk . CONTRABAND POLICY Diamond Offshore Drilling, Inc. employees and employees of its subsidiaries and of other contractors and companies that illegal and unauthorized drugs (and related suspicious paraphernalia), narcotics, alcohol, firearms, etc. are not permitted on board any Diamond Offshore Drilling, Inc. Facilities. Ocean General • Our People • How We Manage HSE on Our Rig? • Ongoing HSE Program • Basic HSE Rules Ocean General – Our People Operation Manager Shorebase Materialman HSE Supervisor Onshore Offshore OIM SDR Electrician Toolpusher Mechanic Motorman Store man Sub Sea Driller Barge Master Ballast Control Operator Crane Operatr Drill Crews Crane Crews Radio Operator Welder How we manage HSE on our Rig? • Applicable local and international regulatory procedures • Global Excellence Management System (GEMS) • DIAMOND & Customer HSE Interface Bridging Document GEMS Global Excellence Management System (GEMS) Diamond Offshore has established the Global Excellence Management System, GEMS. This is a fully integrated Health, Safety, Environmental and Quality (HSEQ) system containing the practical procedures to monitor, control and continually improve performance. GEMS Global Excellence Management System (GEMS) There are 13 elements of GEMS and each of the elements has been given a gemstone name recognizing its precious nature and its essential link in achieving our goals. 1. Pearl – Leadership & Management 8. Emerald – Contract Review 2. Garnet – Risk Assessment 9. Turquoise – Third Party Services 3. Topaz – Training 10. Onyx - Information & Document Control 4. Sapphire – Safety & Environment 11. Jade – Management Of Change 5. Ruby – Operations 12. Opal – Customer Satisfaction 6. Lapis – Maintenance 13. Diamond – Diamond Score Board 7. Amethyst – Audits & Corrective Actions Ongoing HSE Program & Initiatives • Zero Incident Operations (ZIO): • Diligent Observations Decisive Intervention (DODI) Process • Hand and Finger Injury Campaign Hands Free on Loads Gloves Policy Jewelry Policy • Hazard Hunt conducted by Safety Committee for every Quarter or as and when required ZIO Days What is Zero Incident Operations? Initiative to continue excellent operations to avoid injury to personnel, damage to equipment and harm to the environment. In no way do we want to deter reporting of any incident. The goal is to continue our excellent reporting culture and ultimately reduce the incidents! ZIO Incidents Injurious Incident • Fatality • Lost Time Incident • Recordable Doctors Case • First Aid Case Non-Injurious Incidents • Near Miss – High Potential • Near Miss – Medium Potential • Near Miss – Low Potential Dropped Object Incident • DO – High Potential • DO – Medium Potential • DO – Low Potential Oil Spill Incident • DO Reportable Spill to Sea – Greater than 10 gal • Spill > 10 bbl to deck • Contained Spill on Deck • DO Reportable Spill to Sea – Less than 10 gal As of 03rd January 2014, Ocean General has achieved : • ZIO – 26 Days • LTI – 383 Days • RDC– 383 Days • Last FA –21 Days Diligent Observations Decisive Intervention (DODI) Process DODI Process is a Behavior Based Safety (BBS) Program DODI Process is based on behaviors either desired or undesired. With this in mind, the focus is to be on the people both in the application and in the behaviors. All people onboard will use a questioning attitude to identify suspect behaviors. “What can go wrong if I allow this behavior to continue?” • Undesired behaviors are defined as any action that could possibly cause an injury, incident and or create an unsafe condition that would later cause injury or incident. • Desired behaviors are defined as actions that have a predictable safe result and will put no one in harm’s way. SEE IT- OWN IT- FIX IT !! DODI Process DILIGENT OBSERVATIONS DECISIVE INTERVENTION Describe the Behavior: (desired or undesired) The focus of your observations is to be on behaviors: -Reinforce the desired behaviors -Correct the undesired behaviors Behaviour that caused to intervene Rig Name: Ocean Observer: Position: PEOPLE Position Date: Desired Undesired Behavior Behavior (Place an X on all that apply) Describe the Investigation & Intervention: Struck By Falling Caught Between Lifting Intervention with person or crew responsible to investigate and identify why Hand Placement Grooming / Apparel Hair Clothes Describe the Resolution: (what, when, why, how) Jewelry PPE HOUSEKEEPING Decks Equipment Material Storage Dropped Objects Resolution- agreement on how to avoid undesired behaviour or conditions or encourage desired behaviours TOOLS / EQUIPMENT Condition Use Supervisor: Guards Signature: GEMS Position: Date: JSA Describe crew review: .................................. PTW - LTT ……………………………………………………. Procedures SWP Operations ……………………………………………………. ……………………………………………………. ……………………………………………………. Responsible supervisor addresses issues with his entire crew PTW Permit to Work System is to control any work that may present hazards or high risk to personnel or the integrity of the drilling unit, or conflict with other work by introducing hazards or risks not previously identified. HOT WORK: Work involving open flames or other sources of ignition, or which may have a potential source of ignition. COLD WORK: Work that presents a significant hazard, but no source of ignition PTW – Hot Work Work considered “Hot Work” that requires a permit includes, but is not limited to: • work involving open flame • grinding (outside approved workshops) • electric arc welding • electric induction heating • any work involving explosives • use of powered wire brushes or work that can cause sparks • needle gunning • shot blasting, grit or high pressure water blasting • etc PTW – Hot Work Work considered “Cold Work” that requires a permit includes, but is not limited to: • handling of any substance that could be hazardous to health, including toxic chemicals, • radioactive sources, asbestos, etc. • removals of handrails, deck grating, hatches, safety barriers, where an individual could • fall 6 feet or more • well service operations, such as flowing or testing the well • pressure testing on tanks, lines, pipes and blowout preventers (BOP). etc PTW - Training PTW Training • Level 1, Level 2 and Lock/Tag/Try (LTT) • Training must be completed initially (on your first hitch on rig) and on an annual basis by all personnel using the PTW system. • All Diamond personnel and 3rd Parties that are required to do PTW and LTT training. It is applicable to certain types of work undertaken by any person on the unit, including employees of Diamond Offshore, the Customer and all Third Parties. Job Safety Analysis Job Safety Analysis (JSA) The Job Safety Analysis is a tool that is used daily. ALL personnel are required to undertake JSAs on jobs that they plan to After Action Review (AAR) carry out. The JSA video will explain in Did everything match the original plan? detail the Diamond Offshore Philosophy Were the results as expected? on JSAs. What went wrong? What improvements can be made? Revise the JSA based on the results of the critique Basic Safety Rules All personnel will wear approved Hard Hats, safety shoes, eye protection work clothes and gloves when outside the accommodation; All non-routine works shall be covered by PTW; All incidents, regardless of severity will be reported immediately; Attendance at pre-tour and safety meetings is mandatory; Loose jewelry and rings are not allowed to be worn; Long sleeves work coverall Basic Safety Rules Cont’d A full body harness must be worn when working more than 6 feet (1.8 mtr) above the closest landing point; We practice NO HANDS ON LOAD!!!; Stay clear of suspended load; Etc If in doubt, Safety always takes priority NO EXCEPTIONS! Thank You