Eco Electro Park_Poster final

advertisement

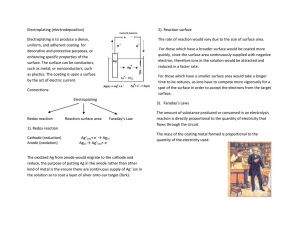

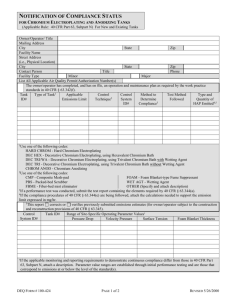

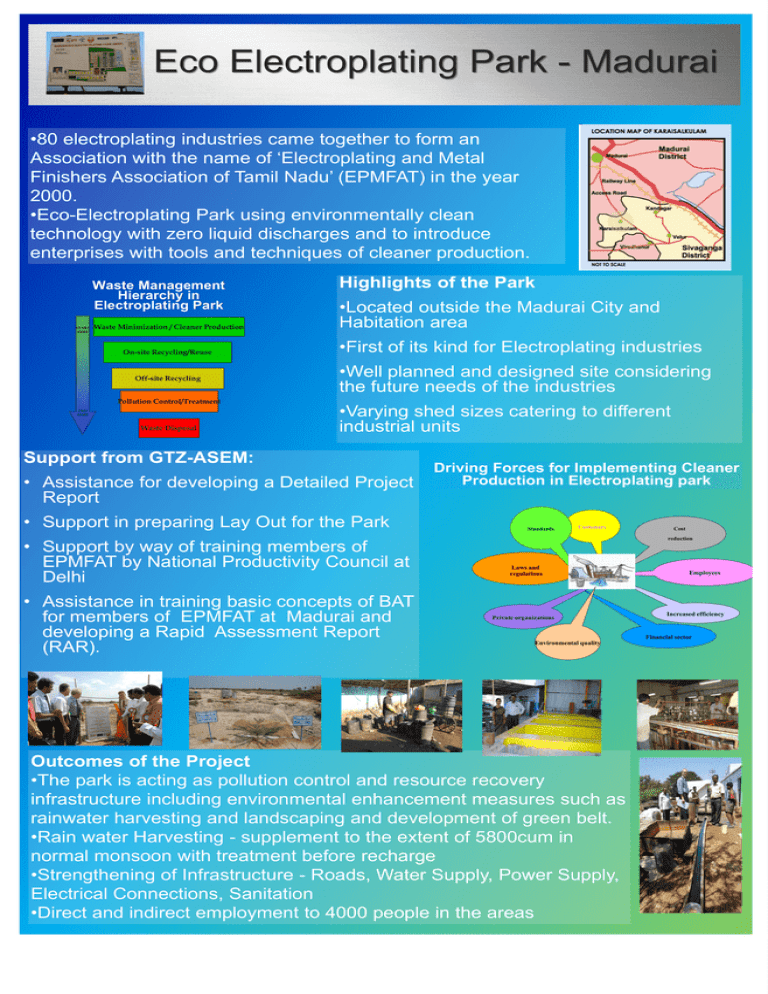

Eco Electroplating Park - Madurai •80 electroplating industries came together to form an Association with the name of ‘Electroplating and Metal Finishers Association of Tamil Nadu’ (EPMFAT) in the year 2000. •Eco-Electroplating Park using environmentally clean technology with zero liquid discharges and to introduce enterprises with tools and techniques of cleaner production. Waste Management Hierarchy in Electroplating Park START HERE Waste Minimization / Cleaner Production On-site Recycling/Reuse Off-site Recycling Pollution Control/Treatment END HERE Waste Disposal Highlights of the Park •Located outside the Madurai City and Habitation area •First of its kind for Electroplating industries •Well planned and designed site considering the future needs of the industries •Varying shed sizes catering to different industrial units Support from GTZ-ASEM: • Assistance for developing a Detailed Project Report • Support in preparing Lay Out for the Park • Support by way of training members of EPMFAT by National Productivity Council at Delhi • Assistance in training basic concepts of BAT for members of EPMFAT at Madurai and developing a Rapid Assessment Report (RAR). Driving Forces for Implementing Cleaner Production in Electroplating park Standards Customers Laws and regulations Private organizations Environmental quality Cost reduction Employees Increased efficiency Financial sector Outcomes of the Project •The park is acting as pollution control and resource recovery infrastructure including environmental enhancement measures such as rainwater harvesting and landscaping and development of green belt. •Rain water Harvesting - supplement to the extent of 5800cum in normal monsoon with treatment before recharge •Strengthening of Infrastructure - Roads, Water Supply, Power Supply, Electrical Connections, Sanitation •Direct and indirect employment to 4000 people in the areas printed by www.postersession.com