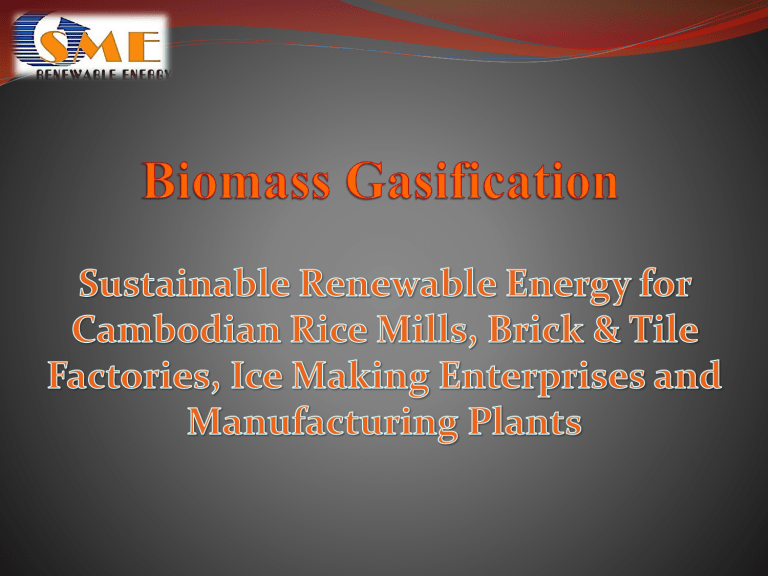

Presentation 4: SME Renewables by Mr. Ho Do Remy

What is Biomass Gasification ?

Conversion of organic materials into combustible gas mixture called SYN Gas or

Producer Gas.

Involves partial combustion of biomass

Four distinct processes occur in the Gasifier as illustrated below:

* Organic materials are living organisms from plants and animals.

The Gasification Process

1. Drying

Removal of Water with Heat

2. Pyrolysis

Decomposition with heat

3. Combustion

Process of Burning/oxidation

4. Reduction

Oxygen lost and Hydrogen added

Biomass From Agro-Forestry Residues

Woody/Bamboo pieces or Chips

Rice Husk

Nut Shell like Coconut, Peanut

Corn Cob

Sugarcane Baggasse

Cashew Nut Shell

Agriculture Waste

Rice Husk

Wood

Corn Cobs

N

2

CO

H

2

CO

2

CH

4

O

2

Syngas or Producer Gas

(Chemical Formula)

Nitrogen

Carbon Monoxide

Hydrogen

Carbon Dioxide

Methane

Oxygen

Syngas/Producer Gas - Composition

Chemical

Compounds

Rice Husk Woody Biomass

CO 15-25% 20-27%

10-15% 10-15% H

2

CH

4

N

2

CO

2

O

2

Upto 4%

45-55%

8-12%

0-0.5%

Upto 3%

45-50%

8-12%

0-0.6%

Above 1050 Above 1100 Gas C.V. (kcal/Nm 3 )

Syngas generated per kg of biomass

2 Nm3 2.5 Nm3

Syngas Characteristics

No Color

Some Odor (distinct “burnt” smell)

Some Impurities (Not Clean)

Poisonous (Health Affecting)

Biomass Gasification Technology,

Gasifier System Components and

Design

Biomass Gasifier – Products

WBG - Woody Biomass Gasifier

FBG - Rice Husk Gasifier

COMBO - Combination Biomass Gasifier

Bin

Hopper

Reactor

Venturi

Scrubber

Heat

Exchanger

Demister

Blower

Filters Gas Line

Gas Flare

Gasifier Body

1- Bunker

2- Hopper

3- Reactor

4- Dry Ash Conveyor

5- Rice Husk Elevator

1

3

2

4

5

Wet / Dry Blower

1- Blower suction adaptor

2- Water injection to wet blower

3- Observation window

4- Blower delivery/outlet

5- Manual gas control valve

6- Separation box gas inlet

7- Separation box

3

2

1

Hot and Cool Gas Lines

6 – Reactor Outlet box

7 – Venturi Scrubber

8 – Hot Gas Temperature

9 – Drain box

10 – Drain Tub

Safety Filter and Passive Filters

Coarse and Fine Filter Lines

Wastewater Treatment Plant

Cooling Tower

ALUM Settling Tank

Charcoal Filter Sand Filter

Biomass Gasifiers System

Size and Capacity

CAPACITY of BIOMASS GASIFIERS

1. Using Rice Husk Fuel = FBG Type Gasifier

2. Using Woody Fuel = WBG Type Gasifier

3. Using Rice Husk and Woody Fuel = COMBO Gasifier

ANKUR Model Sizes FBG : 40, 60, 80, 100, 120, 150,

200, 250, 300, 350, 400, 500, 600, 700, 850

The Largest Size “ANKUR” Type Rice Husk Gasifier is

FBG 850

How to Calculate the Size A Gasifier Running in

Dual Fuel Mode. ( 30% Diesel and 70% Syngas)

Biomass Capacity Table for ANKUR Gasifiers

1. FBG 100 = 120 kg husk per hour

2. FBG 150 = 180 kg husk per hour

3 .

FBG 200 = 240 kg husk per hour

4. FBG 300 = 360 kg husk per hour

5. FBG 400 = 480 kg husk per hour

6. FBG 500 = 600 kg husk per hour

7. FBG 600 = 720 kg husk per hour

8. FBG 700 = 840 kg husk per hour

9. FBG 850 = 1,020 kg husk per hour