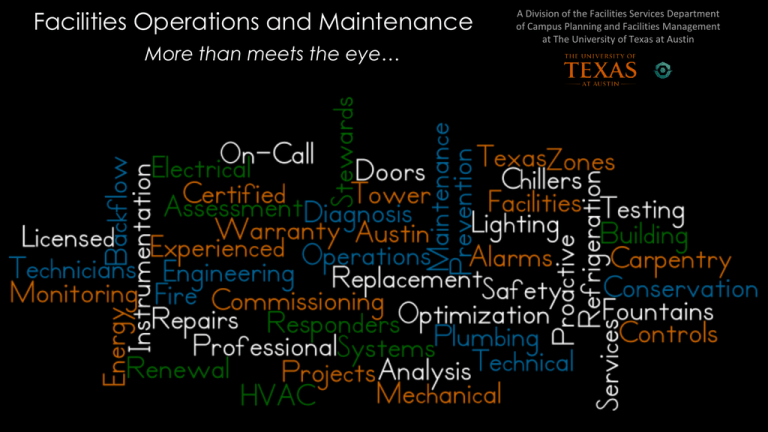

PPTx - The University of Texas at Austin

advertisement

Facilities Operations and Maintenance More than meets the eye… A Division of the Facilities Services Department of Campus Planning and Facilities Management at The University of Texas at Austin Putting it all together… Maintenance Operations Replacement and Renewal Program At Facilities Operations and Maintenance, we are: Facilities Operations and Maintenance Building Operations • Collaborative stakeholders in the university’s academic and research missions • Technically proficient • Good stewards of the university’s time and money Energy and Water Conservation Program Engineering and Technical Support We want to be your service provider of choice. Facilities Operations and Maintenance Technical Expertise Facilities Operations and Maintenance employees respectively hold 252 academic degrees, trade licenses, certifications, and other relevant credentials. Facilities Operations and Maintenance Good Stewards: What Facilities Operations and Maintenance Means to UT • Achieving the expected life of our building systems and equipment • Improved asset reliability – fewer repairs and replacements • Reduced downtime – less disruption to campus community • More efficient service at a lower cost • Proper diagnosis and treatment of maintenance issues • Proactive methods using preventive/predictive techniques Maintenance Operations Replacement and Renewal Program Facilities Operations and Maintenance Building Operations Facilities Operations and Maintenance Management Team Management Team Energy and Water Conservation Program Dan Clairmont Associate Director for Facilities Operations and Maintenance Engineering and Technical Support Zach Adcock Mark White Randy Hooper Ana Thiemer Manager Maintenance Operations Manager Building Operations Manager Engineering and Technical Support Manager Renovation and Renewal Program Energy and Water Conservation Program Maintenance Operations Our customer satisfaction survey says: Our overall “scorecard” average range is 90-95 percent Services By Location • Main Campus Zones: Zone 1 Zone 3 Zone 2 Zone 4 • Dell Pediatric Research Institute (DPI) • Lyndon B. Johnson (LBJ) Library • Pickle Research Campus (PRC): • Additional satellite locations Zone Maintenance Chilling Station Fire Safety Systems Fire-life-safety systems (left) and fire pump (right) A properly maintained sprinkler system is activated, significantly reducing physical damage to the site, and saving lives. Maintenance Operations Services By Type License or Certification Required Clocks and Bells/Carillon Carpentry Repairs Specialized Environments Fountains, Pools, and Turtle Pond Door Repairs Electrical Systems Specialized Equipment Repair After Hours/Holidays Maintenance Services Steam and Plumbing Systems Special Events Heating, Ventilation, Air Conditioning and Refrigeration Systems (HVACR) Lighting Systems Proactive Maintenance Instrumentation & Controls Building Operations Facilities Monitoring Building Automation Systems (BAS) Analysis & Programming Building Optimization Team (BOT) Around-the-clock monitoring of automated building systems helps to limit downtime and prevent loss. BAS analysts provide trouble-shooting and diagnostics to improve building operation performance and reduce energy consumption. BOT assesses how existing building equipment and systems work together, then assist with repairs to increase building and energy efficiency. Engineering and Technical Support Arc Flash Analysis Program Engineering Support Providing technical advice helps our teams improve operational efficiency, prioritize projects, and solve system issues. Warranty and Commissioning Watchful warranty servicing protects our investments. Providing compliance standards and guidelines at UT for working on electrical systems Reviewing projects—from start to finish—helps UT construct a better building with systems that work as intended. Engineering and Technical Support Maintenance Operations Support Zone 1 supervisor consults with engineer Contracted Maintenance Management When highly specialized equipment or service for critical operations are needed, oversight of those contracts helps us get the desired outcomes safely and efficiently. Improving fume hoods, greenhouses, building automation controls, and budget modeling are all part of the Maintenance Improvement Initiative (MI2). Refrigerant Monitoring Program Ensuring Environmental Protection Agency (EPA) compliance for handling refrigerant Energy and Water Conservation Program Our 2020 Vision – Conservation Goals • Reduce energy use by 20% • Reduce water use by 20% • Do it by 2020 TM Dual Approach: Behavioral & Technical Your Energy & Water Conservation Team Energy Engineer measures air flow EWC Initiatives TM Energy Conservation Scorecard TM Baseline Year Total Energy Reduced – Fiscal Years 2009-2013 0% Total % Reduction (Cumulative) % Remaining to Goal by 2020 -2% Percentage Reduced Fiscal Year -4% Baseline 2009 0.0% 20.0% 2010 -1.0% 19.0% 2011 -6.7% 13.3% 2012 -7.9% 12.1% -12% 2013 -12.4% 7.6% -14% -6% -8% -10% Fiscal Years 2009 2010 2011 2012 2013 Data Source: ENURGY Replacement and Renewal Program Prioritization of Projects Facility Condition Assessments Funding Management • Balancing priorities and available resources Inter-departmental team reviewing project criteria • 20,000 square feet in size or above 170 buildings across four sites • Provides overall view and source of data on the condition of our facilities • Vital source of information to ensure effective and efficient use of funds