Introduction to key environmental aspects of

advertisement

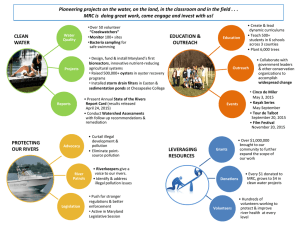

SOURCES OF HAZARDS IN PHARMA Manufacturing and formulation installations. Handling and storage of hazardous chemicals including warehouses, godowns, tank forms in ports/fuel depots/docks. Transportation (road, rail, air, water, pipelines). Emission of pollutants – the air pollutants include carbon monoxide (CO), nitrogen dioxide (NO2), particulate matter of 10 microns or less (PM10), total suspended particulate matter (SPM), sulphur dioxide (SO2), and volatile organic compounds (VOCs). The most common VOCs include methanol, dichloromethane, toluene, ethylene glycol, N,Ndimethylformamide ,and acetonitrile. Effluents, especially those that are not easily biodegradable and toxic in nature. The effluent releases could go directly to streams, rivers, lakes, oceans, or other bodies of water. The releases due to runoff, including storm water runoff, could also be a potential hazard. 2 HAZARDOUS WASTE – TYPES these are in the form of liquids, solids, contained gases or sludge. This waste, containing spent solvents and other toxic organics in significant concentrations, requires treatment before it can be disposed of safely. The toxic releases from the pharmaceuticals industry includes on-site discharge of a toxic chemical to the environment. This includes emissions to the air, discharges to bodies of water, releases at the facility to land, as well as contained disposal into underground injection wells. Natural calamities like such as flood, cyclone, earthquake, tsunami. 3 VARIOUS TYPES OF PHARMACEUTICAL WASTE –CHEMICAL WASTE Organic chemical residues from manufacturing processes Heavy metals Dust during formulation Gaseous Vapours / emissions during API /Bulk drugs Chemical Spills Leakages – water , oils, solvents , chemicals , 4 EXAMPLES OF CHEMICAL WASTE Carcinogenic & other Chemicals used will explore every chances of gaseous/ fumes for Aromatic Amines , Benzene derivatives ,Solvents like Acetonitrile , Acetic Acid , Toluene, Methanol . All are very hazardous for Environment & Occupation . Needs Control measures especially in terms of EMS i.e. Environment Management System ( ISO 14001) and OHSAS – 18001 . 5 MOST COMMON ENVIRONMENT HAZARDS BY PHARMA FIRM The hazards from the pharmaceuticals could be categorized as: Ecotoxic - damage is caused to the environment. Carcinogenic - contribute to the causation of cancer. Persistent - remain dangerous for a long time. Bio-accumulative – accumulates as it makes its way up the food chain. Disastrous due to a catastrophe, mishap, calamity or grave occurrence in any area. 6 CONTD. Water Pollution – because of spillage , drains and generation of effluent water , sewage water for uncontrolled pH , and treating it ineffectively . MOST dangerous for aquatic living organisms or their livelihood. Air Pollution – releases of gaseous , fumes , dust , particulates to atmosphere , poor air quality , Land /Soil Pollution – Spillage , chemicals , oils , lubricants leakages to land /soil – seepage causation of non fertility to soil /lands , dumping or disposal of incinerated sludge unauthorized Noise Pollution – persistent vibration in operating machines , equipments , use of non acoustic power generators , air compressors . 7 CONTD. Odor :- spillage of blood , bio medical waste and culture burning in autoclave etc -poor effect on ambient air quality , -leading to mass air pollution and hazards to neighborhood – plants , trees, human , animals etc . GLOBAL WARMING – CO2 Emission , CO , suspended particulates in atmosphere , NOx , - very sensitive issue globally now posing great threat of GLACIAL melting Heat Stress :- Uncontrolled work environment , high temp , exothermic reactions , use of solvents , - very dangerous occupational hazard and also affecting ENVIRONMENT 8 REGULATIONS AT NATIONAL LEVEL At National Level :FACTORY ACT 1948 Compliance MoEF Environmental Clearance Environment Protection Act 1986 Environmental Statements Submission to Pollution Boards – Form V Public Liability Act & Insurance 1991 MSDS for Hazardous materials and compliance CCOE ( PESO ) License for classified solvent storage Indian Electricity Act 1936 & rules 9 CONTD. Disaster Management Act -2005 Drugs & Cosmetic Act – 1940 Indian Boiler Act 1923 Hazardous Waste Management Act & Rules – The Petroleum Act – 1934 & Rules -2002 The Explosives Act – 1884 & rules -1983 Central Motor Vehicles Act for HW or Goods carrying -1989 10 REGULATIONS AT STATE LEVEL Enforcement at STATE LEVEL : State Level Factory Rules -1963 and further amendments Pollution Control Board Consent To operate – a) WATER ACT 1974 , b) AIR ACT -1984 Stack Monitoring Reports for emissions to Air Work Environment monitoring – Ventilation , Illumination ,Dust & fumes Noise Monitoring Formation of SAFETY COMMITTEE as per 73 L 11 CONTD. Hazardous Waste Disposal Records (manifest) Petroleum products storage on site – type ,storage , and License – class A solvents , Class B chemicals , HSD , LPG stock etc Fire Hydrant system & FIRE NOC Trained FIRST AIDERS EPR & ERT – Emergency Preparedness & Response , Emergency Response Team OHC – Occupational Health Centre , with Visiting Doctor & Male Nurse 12 CONTD. Approved Licensed Contractors ESI of Employees /Contractors / Sub Contractors Mock Drills – announced / un announced for Emergency Evacuation Safety Committee Meetings & MOM Safety & Environment Promotional Activities 13 EXISTING GAPS & CONCERN Non compliance too many – Loose Controls on ETP , Casual Approach for ETP maintenance and Treatment Air Pollution – No proper designing of scrubbers , venturies Storm water and drain water common outlets , effluent load problems Unskilled contract workers Lack of SOP and training needs Staff / workforce in adequate 14 CONTD. Lack of Preventive maintenance activities - Break downs , emissions , leakages –air , water pollution Over capacity utilization of production schedules – system failure , leading to Air /Water /Land pollution Old equipments – Poor Efficiency , trouble shooting , Poor electrical safety – negligence to earthing , fire hazard Spillages , leakages of chemicals , oils , lubricants – water pollution , air pollution , ambience pollution Gaseous emissions to atmosphere in night time high – Air Pollution , poor ambience , plants Use of Non Acoustic D G sets - noise pollution , air pollution 15 GAPS /CONCERNS FOR LEGAL Non adherence to PCB consent norms – diluted standards Erratic Behavior on SAFETY measures Spillages , leakages –ignorance and poor maintenance cause for depletion of natural resources like water , power , forest , ozone layer depletion etc. Non compliance of Annual Environment Returns – forged / manipulations in statement Lack of Safety Standards . 16 MANAGING WASTE COMING OUT FORM PHARMA FIRMS Impact of Waste – from Pharma Firms Air Pollution – 50 % of firms hazardous waste is wrongly handled , not as per MSDS requirements leading to spillage , open to evaporation , unclean dust collectors , inefficient scrubbers , use of scrubber absorption media for a long period . Water Pollution :- Adverse functioning of ETP , lack of monitoring ETP by qualified personnel – leading to profuse water pollution , discharged to CETP with extra allowance , non standard use ETP material – in filtration , aeration , 17 CONTD. Spillage , Leakage , emissions , fumes , vapors direct impact on work place monitoring and AIR Quality . Excessive wastages from R M , storage packing material consumptions ,resulting in to natural and other source depletions Land fertility problems due to waste dumping 18 COMMONLY APPLIED SYSTEMS (DO’S & DON’TS ) Most of the organization switching to water based / enzyme based products – API / formulations – improved Environment Controls for emissions, air quality and water pollution , optimize the process conditions Organizations adapting to ISO -14001 – EMS for continual improvement Work place environment and ambience improvements with designed Aspect /Impact controls , Waste minimization by improving material consumptions. 19 CONTD : Even establishing OHSAS culture for Behavioral safety Internal audits / self inspection to ensure conformance Training to employees / contractors Lock out /Tag Out Electrical system applied Work Permit systems 20 GMP system – Process Approach , validation, compliance Environment Controls during manufacturing , maintenance , storage , transportation , handling . MSDS for base line requirements Documentation and records of H W collection and disposal monitoring Improve on Technology Training of employees , contractors 21 Start Up / Shut Down procedures is must for better environment Controls Improve on Engineering Controls to mitigate aspect /impacts also unsafe conditions and unsafe acts Controls on interfaces of process Establish EHS policy and communicate to all employees , contractors , visitors Provide primary , secondary containments at spillages /leakages to arrest impact on environment 22 Haste , Overloading of equipments Small spills , leaks - ignorance Use of excessive materials – R M , Packing etc . short cuts , process bypasses Critical process – untrained persons 23 GOOD PRACTICES Training to employees / contractors Documentation Recording Self Inspections /Audits Display of various Environment educative posters Tool Box Talks at shop floors Adoption of GMP Consider ISO -14001 –EMS for continual improvement 24 ROLE OF KEY ACTORS IN MANAGING THE WASTE COMING OUT PHARMA INDUSTRIES Government (national and state levels) Making Policies & Establish Refreshing the changes / amendments in policies , directives through Web , Media and Updating the MoEF Consents Survey of Industrial areas though PCB , DISH Creation of CETP or Enviro Collection centers in Industrial outlets Air Monitoring at Industries Work Place Environment monitoring 25 CONTD. Central & State Pollution Control Boards Independent , Full Time MEMBER SECRETARY at PCB Apex level of IAS grade . Creation of Regional PCB at all District level to ease out local issues Public Liability Insurance Act 1991 made mandatory for off site emergency Central Hazardous waste collection areas ear marked by PCB to avoid unauthorized and suspicious dumping Provision of CETP Industrial frequent visits and follow up on critical env.issues 26 CONTD, Violation memos to trouble shooter industries Show cause Notices on major violation of EPA 1986 act Shut down of major problematic Industries Mandatory to file /submit quarterly hazardous waste statement to PCB In line WEB access to all industries by PCB for ease of submission and monitoring by them . 27 DRUG CONTROLLER NATIONAL & STATE LEVEL Responsible for Drug & Cosmetic act enactment in pharma industries. Empowered by Ministry of Chemicals for effective implementation of Drug & Cosmetic act in totality Sampling of vehicles and industries for controls taken on hazardous waste generation and it’s disposal 28 PHARMACEUTICAL ASSOCIATIONS CHEMIST ASSOCIATIONS Interactions , dialogues with local industrial for their problem Arranging work shops / seminars through associations to diffuse the gravity situations and joint forums to mitigate issues of hazardous waste Making presentation to Drug Authorities for facts and getting their help in disposal of hazardous waste like creation of authorized dumping outlets, Creation of CETP or Enviro care centers through follow up with Regulatory authorities and standardize practices Helping to small scale industries through Training and awareness for acquainting to Pollution /Environment Controls 29 MEDICAL REPRESENTATIVE ASSOCIATION CONSUMERS/CITIZENS GROUPS Main role by these group is expected through campaigning for hazardous waste generation by consumers through blisters , primary secondary packing material coming out of drug usage This group to educate hospitals , nursing staff , dispensary staff for impact of packing material in Environment Hazards of handling such waste while as an end user It is expected also by this group to share feedback from customers- direct/ indirect agencies to pharma company so that there will be further improvement to mitigate on issues of hazardous waste by technology developments and less impact on environment 30 END OF SESSION THANKS 31