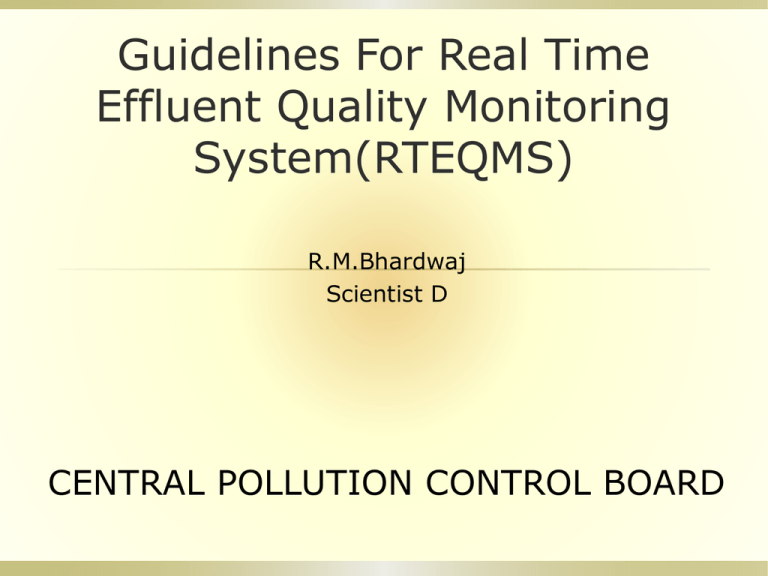

Guidelines For Real Time Effluent Quality Monitoring System

advertisement

Guidelines For Real Time Effluent Quality Monitoring System(RTEQMS) R.M.Bhardwaj Scientist D CENTRAL POLLUTION CONTROL BOARD Background Central Pollution Control Board issued directions to SPCBs/PCCs for setting up of Real Time Monitoring Systems in February 2014. Regulation on method of monitoring and analysis for Real Time Monitoring Systems does not exist and required to be mandated by SPCBs/PCCs as a self regulation mechanism. Regulatory Regime Consent orders of SPCBs/PCCs specify standards to be complied by industries Industries submit analysis reports to SPCBs/PCCs and invariably copies are marked to CPCB Reports submitted by industries largely comply with the consent standard limits in contrast to the samples collected by SPCBs/PCCs/CPCB that by and large remains non complying. Actions (based on manual monitoring methodology) against industries are not leading to improvement in treatment processes by the units besides the willingness of persistent defaulters remains non committal. Regulatory Regime (contd.) Monitoring mechanism is weak due to lack of logistics, manpower and resources among the SPCBs/PCCs/CPCB obviously due to vastness of the jurisdiction area for regional offices and Zonal offices. Remedy is to put in place alternate monitoring mechanism on self monitoring methodology by industries and provide online data to regulatory regime. Limitations of the remedy is to modify the consent mechanism wherein online monitoring and reporting has to be made mandatory Guidelines for RTEQMS Industrial units shall inform SPCBs/PCCs/CPCB about setting up of RTEQMS by submitting installation and commissioning reports with the technical details of equipment's and their worthiness. RTEQMS should be equipped to analyse specified parameters Parameters (pH, Total suspended solids, ammonia, Bio-chemical Oxygen demand (BOD) and Chemical Oxygen Demand (COD) etc.) on a defined frequency. RTEQMS shall consist of standalone unmanned water monitoring stations/system equipped with GSM/GPRS modem and other communication modes for transmission of real time data to a central receiving station(CRS) Guidelines for RTEQMS (contd.) CRS/Server to be located at industrial unit/service provider/SPCBs/PCCs and CPCB. Central receiving station should have capability to receive, analyze and archive the data received from RTEQMS with alarm system. Physical verification of installation of equipment's shall be carried out by SPCBs/PCCs and compile reports with photographic evidence. Verification of data generated through RTEQMS shall be cross checked by manual monitoring and analysis of effluent samples by SPCBs/PCCs to assess the efficacy, accuracy, precision and reliability of equipment's. Site Selection Fixing of site for installation of RTEQMS should be representative and in compliance to provisions of Consent Management (notified effluent outfall with coordinates-Global Positioning System) to assess temporal changes in the quality of effluent discharged from the premises of industrial unit. Monitoring site should be accurately displayed with written station location. Photographic evidence should be obtained in the documentation. Instrumentation of RTEQMS Various equipment manufacturers in India and Abroad are capable to supply, install, commission and operate the RTEQMS. Technology providers have analyser as well as sensor based equipment's to cater to the needs of RTEQMS. General guidelines shall not specify the equipments and technology to be used for setting up of RTEQMS Market based system shall be governed for setting up of RTEQMS Industrial units/associations shall use the equipment and service providers based on the economics and ruggedness for RTEQMS to last longer (say at least 5 to 8 years) Advantages and Disadvantages of Flow Through System Advantages and Disadvantages of Insitu Monitoring System Data Management and Quality Checks • • RTEQMS generated data should be validated according to Water Quality Criteria/Effluent Discharge Standards using the methodologies included in the publication of American Public Health Association on Water and Waste Water Examination(20th Edition) Sensors/analyzers shall have current US EPA reference or equipment method designation and shall be of the latest design. Data Management and Quality Checks (contd.) • Standard Operating procedure should be provided and must contain o o o o o o o Operating procedures for all analyzers and sensors Calibration procedures Calibration schedules Maintenance procedures Maintenance schedules Data Transmission procedures Data validation procedures Network Architecture Network architecture should be modular RTEQMS should be operational in a real time mode and central station should be able to access RTEQMS should be field operational and tolerant to extreme environmental conditions , in high or low temperatures, high humidity coastal conditions and high temperature. RTEQMS should be rugged and should not require manual intervention except routine calibration Communication between RTEQMS and Central Receiving station must be two-way communication system utilizing GPRS/any other telemetry system. Network Architecture (contd.) RTEQMS should have built in GPS receiver for automatic position determination and web camera to visualise the surroundings of effluent channel and virtual flow. Central Receiving station must have the capability to remotely configure, receive, process, archive and visualize data collected and transmitted from RTEQMS to serve through WEB dissemination System should have WEB software to distribute the data to authorized users with highly secured mode through a Quality Control Process. WEB Software Platform Web Software Platform must be able for web posting of the data available on the central server in such a way that all authorized persons with an internet connection (ADSL) would have the possibility to access to the information of all the RTEQMS Web Enabled Software must have following features: o Log of user accessing the web enabled data with complete detail of data accessed and downloaded should be maintained. o Authorized user should have access to current data and historical data. WEB Software Platform o o o (contd.) RTEQMS must show the geographical information and status of the stations, for example Name of station, Station ID, Latitude, Longitude, Height (msl) etc. On selecting a station, the complete menu of the data should be displayed. Data should be accessible in Tabular and graphical format provided by the authorised user. General Specifications -RTEQMS Equipment's should be capable of operating in a self-powering mode from an internal power supply (using cell batteries/alternative system) with a full payload at a defined sampling interval. Equipment's should have a non-volatile flash disk memory capable of storing individual readings for a period of at least one year. Loss of power should not cause loss of memory Technical Specification of Analysers/Sensors pH (mV) Parameter Technical Specification Measuring Range 0.0 to 14 units of pH Accuracy ≤ 0.01 units of pH Response Time ≤ 60 seconds Operating Temperature 0 to 40o C Operating Humidity 5 to 95% non-condensing Power 12 VDC Nominal Cleaning Self-Cleaning ( Automatic ) COD (mg/l) Parameter Measuring Range Accuracy Technical Specification 0.0 to 500 mg/L ± 2% + 5 mg/L of certified reference standard Resolution Response Time Operating Temperature Operating Humidity Power Cleaning ≤ 1 mg/L ≤ 60 seconds 0 to 40o C 5 to 95% non-condensing 12 VDC Nominal Self-Cleaning ( Automatic ) BOD (mg/L) Parameter Technical Specification Measuring Range 0.0-50 mg/L Resolution ≤ 1 mg/L Response Time ≤ 60 seconds Operating Temperature 0 to 40o C Operating Humidity 5 to 95% non-condensing Power 12 VDC Nominal Cleaning Self-Cleaning ( Automatic ) Ammonia (mg/l) Parameter Measuring Range Accuracy Resolution Response Time Operating Temperature Operating Humidity Power Cleaning Technical Specification 0.0 to 100 mg/L ≤ 3% of full scale ≤ 0.1 mg / L ≤ 60 seconds 0 to 40o C 5 to 95% non-condensing 12 VDC Nominal Self-Cleaning ( Automatic ) Total Suspended Solids (mg/l) Parameter Technical Specification Measuring Range 0.0 to 200 mg/l Accuracy ≤ 5 mg/l Response Time ≤ 60 seconds Operating Temperature 0 to 40o C Operating Humidity 5 to 95% non-condensing Power 12 VDC Nominal Cleaning Self-Cleaning ( Automatic ) Experience on Real Time Water Quality Monitoring of River Ganga and Yamuna Automatic Water Quality Monitoring of River Ganga First attempt of Automatic Water Quality Monitoring of River Ganga -1992-95 System performed for a couple of months System did not have telecommunication system Data downloading through floppy diskettes Monitoring data have erratic values System did not improved despite efforts Contract with the supplier of floating boat and equipments terminated Led to arbitration and litigation Bitter experience for two decade Automatic Water Quality Monitoring of River Ganga Automatic Water Quality Monitoring of River Yamuna Second attempt of Automatic Water Quality Monitoring of River Yamuna -1998 Monitoring system was analyser based Container size for equipments was 15x20 feet System performed for a couple of months System did not have telecommunication system Data downloading through floppy diskettes Monitoring data have erratic values System did not improved despite efforts Real Time Water Quality Monitoring of River Ganga and Yamuna Third attempt of Real Time Water Quality Monitoring of River Ganga and Yamuna -2012 Monitoring system is sensor based System functioning for a period of 12 months System have telecommunication system Data transmission through telemetry in server installed in CPCB Delhi Office Monitoring data is under going verification through manual monitoring System has strengths and weaknesses Possibilities of improvement is being explored Monitoring Location River Ganga 01. 02. 03. 04. 05. 06. 07. 08. Haridwar- Upper Ganga Barrage-BhimGoda) Kannauj (Nanamau Bridge), Downstream Kanpur (Jajmau Bridge Kanpur) Allahabad (Shastri Bridge), Upstream Varanasi, Upstream Varanasi, Downstream Gandhi Ghat, Patna (floating platform) Garden Reach, Kolkata River Yamuna 09. Delhi Upstream, Wazirabad 10. Delhi Downstream Okhla Monitoring Location Real Time Water Quality Monitoring of River Ganga and Yamuna Salient Features of RTWQMS RTWQMS Project consists of 10 standalone, unmanned remote water quality monitoring System stations can monitor ten parameters pH Turbidity Conductivity Temperature Dissolved Oxygen Ammonia Bio-chemical Oxygen Demand (BOD) Chemical Oxygen Demand (COD) Nitrate Chloride Monitoring frequency is set for 15 minutes. Real time data transmitted through GPRS network to server of central receiving station at CPCB office Components of the System Real Time Water Quality Monitoring System (RTWQMS) comprises of Monitoring Station-Data logger Data logger and transmission system with build in display Compressor-Solar panel-Battery-GPS-GPRSCamera Sensor package Enclosures Wireless network-GSM/GPRS transmitters Battery Charging System for remote stations (battery, regulator, solar panel) Single Point Grounding System for field stations Floating Platform/Buoy Data processing and publishing server Alert system Monitoring Station Jajmau Bridge KanpurFixed Varanasi DownstreamFloating Monitoring Station-Floating River Ganga-Varanasi Downstream-Floating River Gomti-Lucknow-CWC Station Data Logger and Battery Data Logger Battery Back Up Sensor Cage with sensors on Floating Station Set of four Sensor Monitoring Station-Fixed Shastri Bridge-Allahabad Shastri Bridge-Allahabad Monitoring Station-Fixed Anchor of Cage to Bridge Pillar Anchor of Cage to Bridge Pillar Data Logger connected to Sensors Central Receiving Station Comprising of three Servers Data collection and Data base server - Windows Server Edition, Software with SQL Database Real-time Quality Control Software for alarms by SMS messages based on thresholds Quality Assurance and Application Server (Windows Server Edition), Time Series Web Accessible Remote Station and Computer Maintenance Log Software WEB Server, Data Dissemination/visualization software UPS for Computer Systems Computer Rack Network Router with Hardware Network Switch (HUB) Data Management Online data validation at each station with the con::cube / moni::tool features Software installed on Central Receiving Station has provision for data acquisition, data archival, data analysis, data display and report generation with parameter value graphs Possible to process and further analyze all the measured and calculated parameters from these ten remote stations. Central Monitoring and Alert System Hydro – Q a web based Central Monitoring System provides information about electrical and general parameters online System allows authenticated users to view textual and graphical reports including trends of all configured parameters Integration with google maps provides a one point view of all site information. Limitations/Achievements of Monitoring System Site selection and Timely clearance/permission for installation • Taxation for an overseas vendor •Frequent calibration is required • Security in remote areas a cause of concern • Wide variation in real time values in respect of some parameters (BOD,COD and Nitrate) however relatively reliable observations in respect of other parameters (pH, DO, Temperature, Colour, Conductivity, Turbidity, Chloride and Ammonia) • Limitations/Achievements of Monitoring System (contd.) System is workable however drop time observed invariably due to communication failure or power disruption •Data used during Maha Kumbh Event and with respect to issues with water quality intake point of Delhi on Yamuna for instant reporting •Direction issued to SPCB for corrective action on water quality deterioration at water intake point of Delhi and regularly used during Maha Kumbh event. •System will be helpful for Govt. organisations struggling with manpower. •Limitations shall be huge investment and skilled manpower. • HYDROLOGY PROJECT – II LOAN NO. 4749-IN International Competitive Bidding (ICB) for Procurement of supply, installation, testing, training and commissioning of Real Time Water Quality Monitoring Stations (RTWQMS). IFB No: ICB No: HP II/CPCB-1 /2011-12 Bid Evaluation Report- Vol. 1 ICB –Tender Quotations Name of Bidder Bid Amount Wintech Engineers Pvt. Ltd., Rs.7,90,82,000/New Delhi,India Tritech Engineering & Testing Rs. 5,61,96,196/(Singapore) Pvt. Ltd., Singapore Essel Shyam Technologies Ltd., Rs.1,51,30,267/NOIDA, India Elcome Technologies Pvt. Ltd., Rs. 8,99,34,030/Gurgaon, India SGS Weather & Environmental Rs. 9,36,48,545/System Pvt. Ltd., New Delhi, India Details of Bid Quotation Sl. No. Name of Item Specification or Part No. Sl.No. Name of Item Detail Qty. Rate Value Qty Rate Value 1 Basic item Real Time Water 10 Quality Monitoring System as per the details of TS INR 1,429,670 INR 14,530,446 (including inland transportation and other services) 2 Central Central Receiving 1 Receiving Station at CPCB as Station per the details of TS INR 4,737,429 INR 4,737,429 Total (1+2) 3. Goods Real Time Water 1 Lot Manufactu Quality Monitoring red in the System as per details Purchaser’ of TS s Country Central Receiving 1 Lot Station at CPCB as per the details of TS Total (3) INR 19,267,875 INR 2,083,646 INR 452,147 INR 2,535,792 Details of Bid Quotation Sl. No. 4.1 4.2 Name of Item Related Services Installation, Testing, Calibration, and Commissioning of RTWQMS including civil works Training of CPCB personnel in all activities 4.3 Operation of CPCB Data Center, including Data Collection, Data Storage, Data Validation, Data Dissemination and servicing of all software/ hardware 4.4 Cost of GSM/GPRS Data Transmission during installation, testing & calibration and warranty period Maintenance Manuals, maintenance database and SOP( two numbers) at each site O&M of the system during the two years of warranty following the final acceptance of the system Total Bid Price 4.5 4.6 Qty. Rate Value LS (1 INR 3,095,352 Lot) INR 3,095,352 LS (1 INR 631,800 Lot) LS (1 INR 949,806 Lot) INR 631,800 LS (1 INR 186,030 Lot) INR 186,030 LS (1 INR 585,000 Lot) INR 585,000 INR 949,806 LS (1 INR 10,049,375 INR 10,049,375 Lot) INR 15,497,363 Details of Bid Quotation Sl. No. Name of Item /AMC Rate 5.1 Hardware Maintenance (Post-Warranty Period) 5.1.1 Central Receiving Station INR 1,610,329 5.1.1 RTWQMS INR 3,732,414 5.1.3 Software Licenses & Updates INR 0 5.2 5.2.1 Technical Services Operating & maintenance staff [to be detailed] INR 12,542,445 5.2.2 Telecommunication costs (GSM/GPRS) INR 252,720 5.2.3 5.3 Licenses, Fees Web Other Recurrent Costs INR 0 5.3.1 Burglary Insurance for all the equipments INR 73,519 5.3.2 Fire & Natural Disaster Insurance for all equipments INR 157,238 5.3.3 Specialist Annual Consuttancy on WQ Data INR 526,500 Total Price INR 18,895,166 Post Warranty Related Services Total Years No. 1 1.1 1.2 2 3 3.1 3.2 3.3 4 Component Hardware Maintenance (Post-Warranty Period) Central Receiving Station RTWQMS Software Licenses & Updates Technical Services Operating & maintenance staff [to be detailed] Telecommunication costs (GSM/GPRS) Licenses, Fees Web Other Recurrent Costs 4.1 Burglary Insurance for all the equipment's 4.2 Fire & Natural Disaster Insurance for all equipment's 4.3 Specialist Annual Consultancy on WQ Data Annual Subtotals: Y3 Y4 Y5 INR 510,810 INR 1,119,338 INR 0 INR 536,351 INR 1,306,538 INR 0 INR 563,168 INR 1,306,538 INR 0 INR 1,610,329 INR 3,732,414 INR 0 INR 3,978,571 INR 4,177,500 INR 4,386,374 INR 12,542,445 INR 84,240 INR 84,240 INR 84,240 INR 252,720 INR 0 INR 0 INR 0 INR 0 INR 25,773 INR 24,485 INR 23,261 INR 73,519 INR 55,123 INR 52,367 INR 49,749 INR 157,238 INR 175,500 INR 175,500 INR 175,500 INR 526,500 5,949,356 6,356,980 6,588,830 TOTAL INR 18,895,166 Thank You