Insulation Overview

advertisement

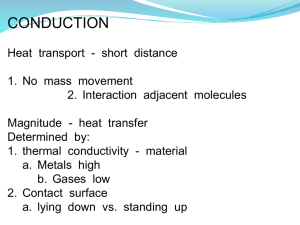

Insulation Overview ** Not for Distribution Outside NSF/UL 440 ** Stan Wolfersberger August 2013 Insulation Overview for NSF/UL 440 • Start with some basics: – What insulation products do – Types of insulation – Performance expectations for insulation – Where insulation is used in buildings • Insulation and Emissions: It Gets Complicated – How a packed wall cavity behaves differently than insulation in a dynamic chamber – Thermal insulation, a temperature gradient is almost always present – Most insulation products are installed behind other products – Simple models do not reflect in-use reality in most cases What Insulation Products Do • Thermal insulation is critical component for energy-efficient buildings of all types (walls, ceiling/roof, slab, foundations, etc. etc.). – From NAIMA website, “The definition of “insulate” as it relates to the flow of heat in homes, buildings and processes means to slow or retard the flow of heat from warmer to colder areas. This happens by surrounding the area with a material with low thermal conductance – such as thermal insulation.” • Building code often mandates the minimum required levels of thermal insulation – Note that adoption of the model energy code by states & local governments may lag by several years from the most current edition for Residential structures. What Insulation Products Do • Besides the “typical” thermal insulation uses in buildings, commercial/industrial applications can include high-temperature equipment insulation, cryogenic equipment insulation, and so on. • Acoustical applications of insulation are also widespread; most thermal insulation types also offer acoustic benefits. • Certain types of insulation may be used as fire blocking, fire safing, etc. • Insulation can provide condensation control. • Some types of insulation may be effective air barriers. Types of Insulation • Fibrous glass, mineral wool (rock wool, slag wool) • Cellulosic materials • Rigid foams (Expanded Polystyrene, Extruded Polystyrene, Polyisocyanurate, Polyurethane, etc.) • Flexible foams (Polyethylene, etc.) • Spray foams (spray-in-place foams dominated by spray polyurethane foams, can be open or closed cell) • Other (foamed glass/cellular glass, aerogels, perlite, vacuum panels, etc.) Performance Expectations for Insulation – ASTM C665, Mineral Fiber Blanket Thermal Insulation for Light Frame Construction and Manufactured Housing • Includes the following material property requirements: – Thermal resistance (thermal conductivity aka R value) – Surface burning characteristics (flame spread and smoke developed) – Critical radiant flux (critical radiant flux-flame propagation resistance) – Water Vapor Permeance (for products faced with a vapor barrier) – Water Vapor Sorption – Odor Emission – Corrosiveness (steel, copper, aluminum) – Fungi Resistance (5 strains of fungus, compared to white birch or southern pine control) Other Expectations – Batt Insulation Example • Contractor and installer requirements can include: – Low dust – Stiffness of batts – Quick recovery to label thickness after opening compressed packages – Parting strength – Value (Cost $$ vs. Benefit) • Federal Trade Commission, “Labeling and Advertising of Home Insulation: Trade Regulation Rule”, 16 CFR Part 460, covers R-value tolerances, acceptable test methods for Rvalue, product labeling, etc. Each Type of Insulation Typically Has its Own Consensus Standard of Required Properties •ASTM C739, Cellulosic Fiber Loose-Fill Thermal Insulation •ASTM C1289, Faced Rigid Cellular Polyisocyanurate Thermal Insulation Board •ASTM C578, Rigid, Cellular Polystyrene Thermal Insulation •ASTM C1029, Spray-Applied Rigid Cellular Polyurethane Foam Thermal Insulation Commercial Buildings & Insulation Single-Family House & Insulation Insulation in Wall Cavities Insulation Behavior in a Wall Cavity – Static Chamber Tests Give Insight Explore Loading Impact on Product Emissions with Static Chamber Tests Typical Data – Emissions Go Down as Loading Goes Up (Formaldehyde, Desiccator Test) Loading, m2/m3 Emissions, ug/m2-hr Product A 0.49 93.1 (~ 9:1 ratio from low to high loading results) 1.78 24.8 2.83 10.6 Product B 0.49 68.2 (~ 3:1 ratio from low to high loading results) 1.78 30.5 2.83 27.2 Understanding the Loading Effect Loading Effect Has Also Been Observed in Dynamic Chamber Tests • Work done at Oak Ridge National Laboratory for CPSC by Matthews and Westley (see “References – Insulation and Related Products SJW 2013”). • Also see work by Pickrell, et al. for CPSC, both static chamber and dynamic chamber tests. This includes the impact of testing products together. Loading impact studied for wood products in static chamber tests (see “References – Insulation and Related Products SJW 2013”). Thermal Insulation – Almost Always a Temperature Gradient Across Product Most Insulation Products Are Not Directly Exposed – Behind Other Products Some “System” tests have been run, but they over-simply real-life situation • Simulated wall stud cavity tests, with metal or wood studs, insulation, with/without drywall, vapor barrier, paint using dynamic chambers. • These tests show that having products over the insulation reduces emissions. • However, there was no temperature gradient, no path for emissions to go “outside” vs. in, no differential pressure driving force, etc. • Trying to simulate actual in-use emissions would overly complicate the test procedure. Understand the Limitations of the Simple Models – Outside the Building Interior, They May Not Reflect Reality Vapor Barriers May be Integral Components of Installed Insulation • Pipe insulation example • Manufacturers provide accessory sealing tapes, butt strips, mastic, etc. so the insulation system is protected by a vapor barrier • Such products may need more specific sample prep/testing instructions if dynamic chamber tests are to be representative of installed products. Some Key Take-Aways - Insulation • Dynamic chamber testing can be used to determine emissions from insulation products; however, the simple models in use are generally overly conservative and do not reflect in-use dynamics. • Once you go outside the interior space, application of simple models may produce misleading predictions of indoor air quality impact of products like insulation. • When there are multiple models which differ in modeling assumptions, then the required emissions for insulation can differ (see my previous examples from CA SM V1.1 for E&P TG meeting). • Simple model(s) are Ok for taking dynamic chamber emissions results and producing predicted air concentrations to see if a product meets low-emitting criteria. But keep in mind their purpose – to compare products, not to predict actual VOC concentrations inside a real building. Additional Sources of Information • Trade Associations – North American Insulation Manufacturers Organization – Cellulose Insulation Manufacturers Organization – Extruded Polystyrene Foam Association – Spray Polyurethane Foam Alliance – Expanded Polystyrene Industry Alliance • Building Science – Manufacturer’s or Trade Association websites – Building Science Consultants, Researchers including U.S. National Labs such as Oak Ridge, Berkeley, as well as private and non-U.S. labs (Building Science Corp; Fraunhofer Institute for Building Physics; etc.) as well as organizations such as The Energy & Environmental Building Alliance. Thank You! Any Questions??? *** Reminder, not for distribution outside NSF/UL 440 ***