advertisement

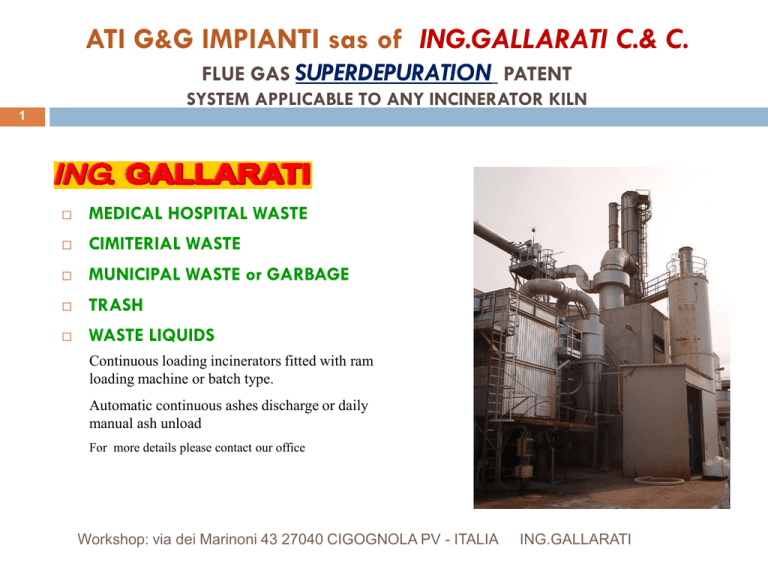

ATI G&G IMPIANTI sas of ING.GALLARATI C.& C. FLUE GAS SUPERDEPURATION PATENT SYSTEM APPLICABLE TO ANY INCINERATOR KILN 1 MEDICAL HOSPITAL WASTE CIMITERIAL WASTE MUNICIPAL WASTE or GARBAGE TRASH WASTE LIQUIDS Continuous loading incinerators fitted with ram loading machine or batch type. Automatic continuous ashes discharge or daily manual ash unload For more details please contact our office Workshop: via dei Marinoni 43 27040 CIGOGNOLA PV - ITALIA ING.GALLARATI ATI G&G IMPIANTI sas of ING.GALLARATI C.&C. PATENTED FLUE GAS SUPERDEPURATION SYSTEM APPLICABLE TO ANY INCINERATOR KILN SYSTEM SUITED FOR INCINERATORS SERIES ROT, MAC, PS ING.GALLARATI TRADE NAME 2 MAIN STAGES (PHASES) OF THE RETROFIT DRY SUPERDEPURATION SYSTEM (patent registration Nr. MI2007A 002192) The system can be added also to existing plants. • First saturation of flue gas with reactant aqueous solutions to convert the volatile strong acid gases as HCl and SO2 into less corrosive and more soluble weak acids to protect the subsequent heat exchangers • Very quick flue gas cooling to a temperature below 200°C, through a boiler or through different heatexchangers to recover heat (hot water, hot air, steam etc.) and electric energy (by means of a turbine). • High efficiency acid gases absorption through an high turbulence reaction chamber (REAK), where are injected specific reactant powders, collected to the bottom and continuously recirculated. • Very fine filtering through an heavy tissue bags-house filter (exit level < 0.3 mg/Nm3) • Very quick and violent flue gas chilling to achieve aerosol droplets separation by means of condensation, through a vertical pipes-bundle (concentric spirals pipe-coils), double pass (“dry quench” exchanger). • Collection of condensated “aerosols” droplets, separated into a stainless steel tank, positioned under the dry quencher; the collected liquids are used in the incinerator furnace for temperature control • Final dry filtering of flue gas through a battery of activated carbon filters (interchangeable cartridges) • Aspiration through a forced draught ventilator (centrifugal compressor) at high vacuum. • Discharge into atmosphere at very high speed, through a POST-HEATING exchanger, to exhale the flue gas at a temperature set always over 180°C. Workshop: via dei Marinoni 43 27040 CIGOGNOLA PV - ITALIA ING.GALLARATI ATI G&G IMPIANTI SAS of ING.GALLARATI C.& C. INCINERATORS BRANCH ROTATING INCINERATOR KILNS SERIES ROT LARGE WASTE TO ENERGY APPLICATIONS 3 Suited for: PLASTIC WASTE RUBBER HOSPITAL WASTE INDUSTRIAL WASTE GARBAGE & TRASH SLUDGE LIQUIDS Continuous working, waste bunker, ram loading machine, continuous ash unloading system For details please contact our office Workshop: via dei Marinoni 43 27040 CIGOGNOLA PV - ITALIA ING.GALLARATI ATI G&G IMPIANTI SAS of ING.GALLARATI C.& C. INCINERATORS BRANCH 4 SMALL PYROLYTIC INCINERATORS SERIES MAC FOR SLAUGHTER HOUSES AND SMALL COMMUNITIES FITTED WITH MICRO WET DEPURATION SYSTEM Suited for: SLAUGHTER WASTE ANIMAL CARCASSES CIMITERIAL WASTE HOSPITAL WASTE AND GARBAGE SLUDGE AND LIQUIDS Batch or continuous loading by means of a ram loading machine. Daily ash unload For details please contact our office Workshop: via dei Marinoni 43 27040 CIGOGNOLA PV - ITALIA Vs.2012 ING.GALLARATI ATI G&G IMPIANTI SAS of ING.GALLARATI C.& C. INCINERATORS BRANCH FLUE GAS SUPERDEPURATION SYSTEM AT CEE NORMS, INCINERATOR NZEP PLANTS WITH VERY LOW EMISSIONS 5 Workshop: via dei Marinoni 43 27040 CIGOGNOLA PV - ITALIA ING.GALLARATI ATI G&G IMPIANTI SAS of ING.GALLARATI C.& C. INCINERATORS BRANCH FLUE GAS SUPERDEPURATION SYSTEM AT CEE NORMS, COMPLETE INCINERATOR NZEP PLANTS WITH NEAR TO ZERO EMISSIONS INTO ATMOSPHERE (NZEP FLUE GAS CLEANING PLANTS) 6 NZEP flue gas cleaning plant details with relevant chimney working Workshop: via dei Marinoni 43 27040 CIGOGNOLA PV - ITALIA ING.GALLARATI ATI G&G IMPIANTI SAS of ING.GALLARATI C.& C. INCINERATORS BRANCH FLUE GAS SUPERDEPURATION DRY SYSTEMS CEE NORMS, COMPLETE INCINERATOR NZEP PLANTS WITH VERY LOW EMISSIONS INTO ATMOSPHERE 7 A dry cleaning system chimney working with its unvisible smoke ! A modern turbine supplied in partnership with us Workshop: via dei Marinoni 43 27040 CIGOGNOLA PV - ITALIA ING.GALLARATI Vs.2012 ATI G&G IMPIANTI SAS of ING.GALLARATI C.& C. INCINERATORS BRANCH OPERATIVE STRUCTURE 8 Workshop: via dei Marinoni 43 27040 CIGOGNOLA PV - ITALIA ING.GALLARATI ATI G&G IMPIANTI SAS of ING.GALLARATI C.& C. INCINERATORS BRANCH Vs.2012 INCINERATORS ENGINEERING AND PRODUCTION 9 DWG trade-mark ®: Contact information: G.&G. IMPIANTI Sas of Ing.Gallarati C.&C. Local workshop: via dei Marinoni 43 CAP 27040 CIGOGNOLA PV - ITALIA tel. & fax.: ++39.385.250421 e-mail.: ing.gallarati@gmail.com info@ing-gallarati.com further information on the web sites : www.ing-gallarati.com / www.ing-gallarati.net Workshop: via dei Marinoni 43 CAP 27040 CIGOGNOLA PV - ITALIA ING.GALLARATI