Senior Design Night

advertisement

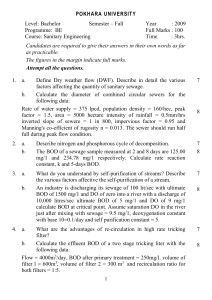

Senior Design Friday, April 23, 2010 Chris Crock Aaron Lammers Brent Long Aaron Raak Carabuela, Ecuador has a flawed wastewater treatment system Overloaded septic tank Failed leaching field Worked with HCJB to remedy the problem Effective Treatment Culturally Appropriate Sustainability Site Appropriate Low Cost User Friendliness Life of Design Water Effluent E. Coli count < 1000/100 mL Biochemical Oxygen Demand (BOD) under 2.0 mg/L Helminth eggs < 1 egg/100mL (WHO standards set E. coli limit for leafy crops at 1,000/100mL; at this level of treatment other pathogens are assumed to be treated as well) Sludge Effluent 1000 E. Coli/gram solids < 1 Helminth egg/ g solids (With alfalfa, requirements need to only meet Class B sludge treatment. The US EPA determined that sludge which goes through one of six processes of significant reduction of pathogens may be applied to crops) Handle the waste of the entire connected population for 20 yrs (1800 residents) No electricity The system must fit in 0.5 hectares No chemical additives Shall not need experts outside of the village for construction General System Description Bar Racks Grit Chamber Settle out discrete organic materials and small particles Store organics for later treatment Anaerobic digestion of organic solids Two tanks and settling chambers Stabilization Lagoons Settle out large particles (sand, grit, etc.) Two open channels acting as grit chambers Velocity control weir Imhoff Tank Racks for large solids and objects Two open channels with inclined bars Dewatering plate for screenings One facultative pond for Biochemical Oxygen Demand (BOD) reduction Two maturation ponds for further BOD reduction and pathogen removal Sludge Drying Beds Treat sludge from Imhoff Tank and Grit Chamber Four sludge drying beds for treatment cycling Q = 192 m3/day BOD = 32 kg/day TSS = 48 kg/day FC = 2x107 /100 mL General System Description Q = 192 m3/day BOD = 32 kg/day TSS = 48 kg/day FC = 2x107 /100 mL Bar Racks Q = 192 m3/day BOD = 32 kg/day TSS = 48 kg/day FC = 2x107 /100 mL Grit Chamber Imhoff Tank Q = 192 m3/day BOD = 16 kg/day TSS = 32.6 kg/day FC 2x107 /100 mL Solids = 16 m3/month Sludge Drying Bed Q = 192 m3/day BOD = 0.51 kg/day TSS = 3.2 kg/day FC = 915 /100 mL Irrigation Stabilization Ponds Important to remove larger solids Bar Racks ▪ Design depends mostly on clear space between bars ▪ ▪ ▪ ▪ Velocity should be within 0.3—0.6 m/s Openings between 20—50 mm Rack for dewatering screenings Redundant system Bar Racks Structural Design Analysis of moments in the chamber Designed steel and concrete for worst case loads ACI 318M-05 Metric Building Code and Commentary Steel reinforcing requirements Concrete requirements Important to remove particulate Grit Chamber ▪ Design largely depends on the velocity the water (0.3 m/s) ▪ Velocity controlled by Sutro weir ▪ Grit removed is treated in sludge drying beds ▪ Redundant system Structural Design Ultimate moment design ACI 318M-05 Metric Building Code and Commentary Two open channels and sutro weirs for redundancy Outflow Inflow V V0 Stokes Settling Velocity Stokes Rearranged for Particle Removal Environmental Design Two tanks in one structure for redundancy Sedimentation ▪ Based off design guides and rules of thumb ▪ Overflow rate of 600 gal/ft2 day ▪ Retention Time of 2 hours Digestion ▪ Based on case study of Imhoff tank in Honduras ▪ Sludge storage for 0.053 m3 per resident (95.4 m3) ▪ Up to 6 months of sludge storage Structural Design Analysis of forces and moments in tank ▪ Finite Element Analysis (FEA) ▪ Structural analysis Designed steel and concrete to hold for highest loads ACI 318M-05 Metric Building Code and Commentary Similar to case study tank in Honduras Final Design: 9.25m long x 8.6m wide x 7.5 m tall Loading Rates BOD: 100mg/L Helminth Eggs: 1000 Eggs/L E-Coli: 2x107 Coliforms/100mL Reduced Rates BOD: 2.7mg/L Helminth Eggs: 0.10 Eggs/L E-Coli: 915 Coliforms/100mL Pond System 1 Facultative Ponds 2 Maturation Ponds Dimensions 48 meters x 24 meters Depths of 1.5 meters and 0.5 meters Redundancy Must hold sludge for several weeks to dewater Must hold sludge for longer to make it safe for fertilizer Designed to hold 1 year’s worth of sludge for Imhoff tank Area: 960 m2 Beds have layers of sand and gravel Shear gates to control sludge flow Low walls of earth or concrete Under drain system of PVC pipe Townspeople connect roof drains to sewers A large rainfall event could flush the system Model showed 15x increase in flow during 10-year event Will require an overflow weir to prevent flushing Storm inflow: 3100 m3/day Design inflow: 192 m3/day Estimated cost of construction = $31,000 Probably too much for residents We wrote a grant to cover the cost of construction Maintenance costs to be covered by Carabuela Estimated $14,000/year Designed a complete system to treat Carabuela’s wastewater for irrigation reuse Removal of BOD, TSS, and Pathogens BOD (98.7%) TSS (93.4%) Pathogen Removal ▪ E. Coli (99.995%) ▪ Helminth Eggs (99.99%) Created construction drawing for the system Wrote an operations and maintenance manual

![Crisis Communication[1] - NorthSky Nonprofit Network](http://s2.studylib.net/store/data/005428035_1-f9c5506cadfb4c60d93c8edcbd9d55bf-300x300.png)