Kayasand V7 sand manufacturing but not as you know it

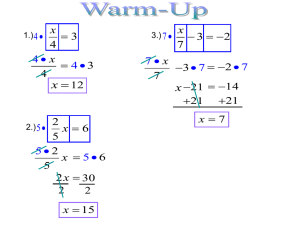

advertisement

Natural Sand Replacement in Concrete Presented by: Martins Pilegis & Andi Lusty 21st September CMIC 2012, Melbourne, Australia The V7 Technology Unique Crushing System There is an autogenous crushing within the particle cloud and on the rock bed for both, the Barmac and V7 Crushers. The V7 Crusher is constructed so there are multiple impacts in the new dense material zone. As the material drops down from the stone wall into an increasingly dense zone, it is re-crushed by particle interaction as well as hammers, being both shaped and scrubbed. Unique Shaping to 75μm Shape of particles <1mm vital • • • Workability Pumpability Density Cone Crusher Barmac VSI V7 Crusher A Unique Separation System • Dust collector Air screen gives partial return, top-size cut and classification. Raw material flows from VSI → diffusion feeder → air screen separation using the blower. (5) is fully returned, and (4) is partially returned by the damper. Top size (1) - (3) and part of (4) screened for oversize return. • VSI Wind power • View showing dispersion system • Diffusion feeder Blower 100 10 90 100 80 90 10 70 80 Passing rate (%) Passing rate (%) Grain size damper 60 70 60 50 50 40 40 30 30 20 Cut screen Product 20 Over size (Return to VSI) 10 0 10 0 0.15 0.15 0.3 0.3 0.6 1.2 0.6 1.2 Sieve mesh (mm) Inner structure of air screen 2.5 Sieve mesh (mm) 2.5 5 5 Unique Flexibility in Gradation A poorly graded crusher dust becomes even poorer after the removal of filler by washing or dedusting. Kayasand is evenly graded and gradations can be changed to make the ideal sand as a single fine aggregate component for concrete or asphalt. Summary of Differences The V7 has a more efficient crusher than other autogenous VSI’s The V7 has an airscreen with the ability to recirculate a variable size of product The V7 can vary the gradation of the sand The V7 can control the minus 75 micron content of the sand The V7 produces a shaped particle size to 75 micron particles The V7 operates dry as well as quietly and dust free Can V7 Kayasand can COMPLETELY replace natural sand in concrete? Cardiff University Research Key Objectives • Primary aim to show that a manufactured sand can be made to replace natural sand and sand blends • Secondary aim to refine gradations to reduce cement usage and to find new uses for rock filler in agriculture Environmental Benefit • If replacement is proven viable then dredging for sand can be reduced or eliminated, and viable concrete sands can be made in most quarries. Manufactured sands Manufactured sands from crusher dusts with at least 4 gradings for each quarry Basalt (B) – Duntilland Quarry, Holcim Granite (G) – Glensanda Quarry, Holcim Sandstone (S) – Gilfach Quarry, CEMEX Limestone (L) – Taff’s Well Quarry, CEMEX 100 100 B-A B-B B-C B-D 80 60 40 60 40 60 40 1 Basalt 10 S-Dust 40 L-Dust 20 0 0.01 0.1 Sieve size, mm 1 60 40 20 0 0.01 0.1 1 Granite 10 10 L-A L-B L-C L-D 80 20 0 0.1 G-Dust 60 S-A S-B S-C S-D 80 20 0 B-Dust 80 100 100 G-A G-B G-C G-D G-E 80 20 0.01 Percent passing, % • • • • 100 0.01 0.1 1 Sandstone Materials: CEM I 52.5 N, Crushed limestone 4/20 mm, Sea dredged natural sand control (N), Mid range plasticizer WRDA 90, manufactured sands 10 0 0.01 0.1 1 Limestone 10 Characterisation tests New Zealand Flow Cone (NZS 3111-1986) Observations from mixing (finishability, ease of placement) Particle size distribution (BS EN 933-1) Plastic Density Slump Water absorption (BS EN 1097-6) Fine Aggregate Methylene Blue Value (BS EN 933-9) Fresh Concrete Air Entrainment Hardened Concrete Flexural strength –28 days GMBV (Grace Rapid Clay test) Sand Equivalent (BS EN 933-8 ) Compressive strength –1 day –7 days –28 days Manufactured sand test results 38.0 Granite Sand B-Dust 36.0 Basalt sand • New Zealand flow cone – simple indirect test indicating shape, grading and surface texture 34.0 32.0 FLOW TIME, s 30.0 • All manufactured sands fit within the standard envelope Sandstone sand L-A 26.0 L-D 24.0 L-B L-C G-A B-A G-B G-E G-D G-C B-B 22.0 B-C S-A NS B-D S-B S-D 18.0 36% S-C 41% VOIDS, % 46% 6 Methylene Blue Value 5 4 3 2 1 S-FEED S-A S-B S-C S-D L-FEED L-A L-B L-C L-D B-FEED B-A B-B B-C B-D 0 N G-FEED G-A G-B G-C G-D G-E Methylene Blue Value, g/g of sand • MBV reduced in all manufactured sands if compared to feed material 0/4 mm fraction S-Dust G-Dust 28.0 20.0 • Methylene blue test – indication of potential presence of clays, Grace’s rapid clay test directly correlated with these results L-Dust NZS 3121 specification envelope Limestone sand Concrete, Stage 1 Stage 1: without plasticizer, aiming for S2 slump, fixed w/c ratio for particular quarry sands which provides S2 slump. Cement FA CA Water 350 753 1040 varies Compressive, flexural strength and slump 70 140 Granite w/c 0.58 Basalt w/c 0.67 Limestone w/c 0.55 Sandstone w/c 0.67 60 120 50 100 40 80 30 1 day compressive strength Slump, mm Compressive, flexural strength, N/mm2 Natural sand w/c 0.48 7 day compressive strength 28 day compressive strength 60 28 day flexural strength 20 40 Slump, mm 10 20 0 0 N slump G-A G-B G-C G-D G-E B-A B-B B-C B-D Concrete mixes L-A L-B L-C L-D S-A S-B S-C S-D Concrete, Stage 2 Stage 2: Varying plasticizer dosage to achieve S2 slump, fixed w/c ratio at 0.55 for all sands. Cement FA CA Water Plasticizer 350 753 1040 193 varies Compressive, flexural strength and slump for w/c 0.55 70 60 Natural sand Limestone w/c 0.55 Basalt Granite 100 Limestone w/c 0.50 Sandstone 90 1 day compressive strength 50 70 7 day compressive strength 60 40 50 30 40 Slump, mm Compressive, flexural strength N/mm2 80 28 day compressive strength 28 day flexural strength 30 20 20 10 10 0 0 N G-A G-B G-C G-D G-E B-A B-B B-C B-D L-A L-B L-C L-D L-A 0.5 L-B 0.5 L-C 0.5 L-D 0.5 S-A S-B S-C S-D Slump, mm Primary Objective • to show that a manufactured sand can be made to replace natural sand and sand blends in concrete V7 sand can COMPLETELY replace natural sands in concrete! The Economics V7-60 Economics (60 tph throughput) Operating Costs Capital Costs • • • Power = 6.7kwhr per tonne throughput @ 15c/kwhr = Aus $1.00 Wear parts and maint = $1.85 to $2.80 depending on material Typical Opex ~ $3.20 /t throughput • • Typical ~ Aus $3m turnkey installation 60tph capacity = 200ktpa+ 10 yr amortisation Typical capital rec ~ $1.50 /t throughput V7-60 Economics (60 tph throughput) Sand Yields Filler (dry premium product) • • • • Range = 75% to 85% Typical = 80% Depends on feed - Crushing properties - Filler content Premium all in fine aggregate ~ $5.80/t (Assuming filler has no value and full capital recovery) 15% to 30% - Granulate – drainage = $15/t - Road base = $20/t - Asphalt/block plants = $20/t - Agriculture = $20/t Significant upside likely from filler The economics compared Kayasand V7-60 Dredged Sand Washed Pit Sand Operating Cost per tonne sand produced $3.00-$3.801 $7.00 to $12.003 $8.00 to $12.005 Capital Cost per tonne per annum capacity $301 $45 to $752 $30 to $454 Nil High High High Med Med Environmental Impact Availability 1 Costs will vary depending on location and feed, these costs are typical of installations Kayasand has completed detailed evaluations for. 2 Allowance for resource consent, dredger, wharf facilities. 3 Will vary depending on the distance off shore for dredging. 4 Allowance for resource consents and capital investment – wash-plant , filter press etc. 5 Wash plant operating costs vary depending on water, waste costs, efficiency etc. The Environment The Japanese Experience •Japan banned unnecessary dredging in 1991 • Kayasand now accounts for 45% of all of their manufactured sand •While the introduction of Kayasand has been successfully implemented and the environment as well as the construction industry has benefited, regulatory change was necessary Driving Change for Environmental Gain There is often resistance to change in any industry due to: • • Vested interests (from existing sand, gravel and dredging companies) • • Relatively slow adopters of proven but novel technology Economic pressures and lack of priority (bigger problems so park this) The environmental cost is not borne by them Acknowledgements Kayasand would like to acknowledge the financial and in kind support of: The Aggregate Levy Fund for Wales Kotobuki Engineering & Manufacturing Company (Kemco) CEMEX Aggregate Industries (Holcim) Grace Construction Products and Cardiff University’s Engineering Department for their input and supervision, in particular Diane Gardner and Professor Bob Lark