19. Compressed Air

advertisement

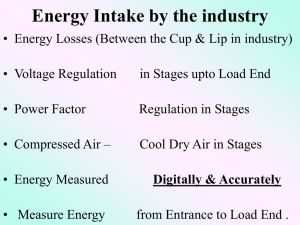

Compressed Air Walter Bright MAE406 – Energy Conservation in Industry wabright@ncsu.edu 10/29/2013 C.A. BASICS C.A. Basics Why Compressed Air? • Compressed air is simply a medium to transmit power, similar to electricity or steam to transmit heat • Often referred to as the ‘fourth utility’ • Compressed air can be used for a multitude of applications – Simple: Pumping up tires and blow-off nozzles – More Complex: Instrumentation, Vacuum generation, Pneumatic tools, cylinders and valves • Ex: flow controllers, pumps, impact wrenches, nail guns, etc – End-use equipment is cheap, lightweight, compact & powerful – Explosive environments – Easy to control (solenoid valves, pressure proportional to force) C.A. Basics Specialized Bicycles/Popular Mechanics Basic Compressor C.A. Basics Why NOT Compressed Air? Typically the most expensive utility at a plant Rule of Thumb: It takes 7 units of compressor horsepower to provide one horsepower of useful work! Why is compressed air so expensive??? Ex: Cost of operating a 10hp motor for 1 year (8,760hrs) 10hp Electric Motor 10hp Pneumatic Motor $5,388 $32,818 C.A. Basics Why Manage Compressed Air? • Surely if it’s the most expensive utility at a plant it’s being continuously managed… • Example: – Foundry Sand Transport System – 350 hp of compressor power – Energy consumption reduced by 36% – $16,300 in annual savings – 1.3 year simple payback • Substantial opportunity throughout industry to reduce compressed air usage and cost • Plant personnel often think compressed air is free Compressed Air Challenge, www.compressedairchallenge.org C.A. Basics 100 kW of electrical energy input MOTOR COMP Greg Harrell, Energy Management Services (EMS) Compression Thermodynamics C.A. Basics 100 kW of electrical energy input MOTOR 5-8 kW of thermal energy loss Greg Harrell, EMS COMP Compression Thermodynamics C.A. Basics 100 kW of electrical energy input MOTOR 5-8 kW of thermal energy loss COMP # kW of loss?? Greg Harrell, EMS Compression Thermodynamics C.A. Basics 100 kW of electrical energy input MOTOR 5-8 kW of thermal energy loss COMP 98-99% Efficient Greg Harrell, EMS Compression Thermodynamics C.A. Basics Compression Thermodynamics 100 kW of electrical energy input MOTOR 5-8 kW of thermal energy loss COMP 98-99% Efficient Greg Harrell, EMS We want highpressure air from the compressor… C.A. Basics Compression Thermodynamics 100 kW of electrical energy input MOTOR 5-8 kW of thermal energy loss COMP 98-99% Efficient Greg Harrell, EMS We want highpressure air from the compressor… What we get is high-pressure, high-temperature air C.A. Basics Compression Thermodynamics 100 kW of electrical energy input COMP We want highpressure air from the compressor… 5-8 kW of thermal 98-99% energy Efficient* loss What we get is high-pressure, high-temperature air MOTOR Greg Harrell, EMS C.A. Basics Compression Thermodynamics # kW of thermal energy loss?? 100 kW of electrical energy input COMP We want highpressure air from the compressor… 5-8 kW of thermal 98-99% energy Efficient* loss What we get is high-pressure, high-temperature air MOTOR Greg Harrell, EMS C.A. Basics Compression Thermodynamics 90 kW of thermal energy loss 100 kW of electrical energy input COMP We want highpressure air from the compressor… 5-8 kW of thermal 98-99% energy Efficient* loss What we get is high-pressure, high-temperature air MOTOR Greg Harrell, EMS C.A. Basics Compression Thermodynamics 90 kW of thermal energy loss 100 kW of electrical energy input COMP We want highpressure air from the compressor… 5-8 kW of thermal 98-99% energy Efficient* loss What we get is high-pressure, high-temperature air MOTOR Greg Harrell, EMS C.A. MTR # kW of shaft energy from comp. air motor?? C.A. Basics Compression Thermodynamics 90 kW of thermal energy loss 100 kW of electrical energy input COMP We want highpressure air from the compressor… 5-8 kW of thermal 98-99% energy Efficient* loss What we get is high-pressure, high-temperature air MOTOR Greg Harrell, EMS C.A. MTR 10 to 20 kW of shaft energy from comp. air motor C.A. Basics 90 kW of thermal energy loss 100 kW of electrical energy input MOTOR COMP 5-8 kW of thermal 98-99% energy Efficient* loss Greg Harrell, EMS Compression Thermodynamics We want highpressure air from the compressor… What we get is high-pressure, high-temperature air C.A. MTR 10 to 20 kW of shaft energy from comp. air motor What about the 1st Law of Thermo?? C.A. Basics 90 kW of thermal energy loss 100 kW of electrical energy input MOTOR COMP 5-8 kW of thermal 98-99% energy Efficient* loss Greg Harrell, EMS Compression Thermodynamics We want highpressure air from the compressor… What we get is high-pressure, high-temperature air C.A. MTR 10 to 20 kW of shaft energy from comp. air motor The 1st Law of Thermo is not violated because the air discharged is very cold C.A. Basics 90 kW of thermal energy loss 100 kW of electrical energy input MOTOR COMP 5-8 kW of thermal 98-99% energy Efficient* loss Greg Harrell, EMS Compression Thermodynamics We want highpressure air from the compressor… What we get is high-pressure, high-temperature air C.A. MTR 10 to 20 kW of shaft energy from comp. air motor The 1st Law of Thermo is not violated because the air discharged is very cold C.A. Basics 90 kW of thermal energy loss 100 kW of electrical energy input MOTOR COMP 5-8 kW of thermal 98-99% energy Efficient* loss Greg Harrell, EMS Compression Thermodynamics We want highpressure air from the compressor… What we get is high-pressure, high-temperature air C.A. MTR 10 to 20 kW of shaft energy from comp. air motor The 1st Law of Thermo is not violated because the air discharged is very cold THE C.A. SYSTEM The C.A. System Compressed Air Challenge Typical System The C.A. System Compressed Air Challenge Supply Side Types of Compressors The C.A. System • • • • Analogy: Car IC Engine How it works: Oil and Oil-free Single-acting and doubleacting • Single or multi-stage, depending on pressure/size • Typically smaller units (less than 30hp*) Compressed Air Challenge (pg. 129) Supply Side Reciprocating The C.A. System • Originally THE compressor technology • Many vintage reciprocating compressors operating today, some in excess of 1,000 hp • THE most efficient compressor technology (double-acting) • Not used much today in industry • 22-24 kW/100 cfm (singleacting), 15-16 kW/100 cfm (double-acting) Belliss and Morcom Supply Side Reciprocating The C.A. System • Analogy: Car turbocharger • How it works: – Impeller spinning at 10,000+ rpm • Typically larger units (300 hp to >4,500 hp) • All Oil Free • Multi-stage, typically 2-4 depending on size/pressure • Centrifugal Compressor Animation Supply Side Centrifugal The C.A. System Supply Side Centrifugal • Low vibration, don’t need a heavy concrete pad like reciprocating • Still very efficient • Favored by industry today for large applications • Operating range limited • 16-20 kW/100 cfm The C.A. System • Analogy: Car supercharger • How it works: – Two screws meshed together which squeeze air • Typically medium sized units (20 hp to 300 hp) but can be as large as 600 hp • Oil and Oil Free • Typically single stage, some larger units 2 stage Supply Side Rotary Screw The C.A. System • • • • Supply Side Rotary Screw By far, most common industrial air compressor today Low first cost, good efficiency, large operating range Variety of control techniques and manufacturers 17-22 kW/100 cfm (single stage) Ingersoll Rand The C.A. System Supply Side Rotary Screw (Lubricant-Injected) Compressed Air/Oil Mixture Oil (Lubricant) “Oil-Free” Compressed Air (2-3 ppm) Credit: Ponna Pneumatic The C.A. System Supply Side Dryers • Air dryers condense water out of compressed air • Air at 80°F and 50% = 60°F dewpoint and 0.01092 lbw/lba • Compressed to 100 psig and 185°F, how much water in air? – Same! 0.01092 lbw/lba Squeeze water into space 8 times smaller (114.7/14.7=7.8) • What is new dewpoint? – 125°F (Rule of Thumb: Double pressure, increase dewpoint by 20°F • What happens if we send that air into a industrial plant that is 80°F ambient? – Rain inside compressed air pipes Compressed Air Challenge The C.A. System Supply Side Refrigerated Dryers • Refrigerated dryers utilize a refrigerant circuit to condense moisture from the air stream • Typical leaving dewpoint of 40°F • Cycling, non-cycling and head-unloading designs • 0.80 kW/100 cfm The C.A. System Supply Side Desiccant Regenerative Dryers • Desiccant dryers use a desiccant to dry the air (via adsorption) • Typical leaving dewpoint of -40°F to -100°F, depending on desiccant type • Heatless, heat-assisted and blower-heat assisted designs • 2-3 kW/100 cfm The C.A. System • • • • • Supply Side Additional Components Storage (Air Receivers, piping, etc) Pressure/Flow Controllers After-coolers Air/Lubricant Separators Filters – Particulate: Removes dirt/debris – Coalescing: Removes vapors (typically oil/lubricant vapors) – Adsorption: Additional hydrocarbons and other impurities • Traps and Drains – Level operated – Timer operated – Zero-air loss The C.A. System Demand Side Usage Breakdown • In a typical compressed air system, how much air is used “appropriately” by production? • Leaks: Compressed air which leaks from distribution • Inappropriate Uses: Anything that compressed air is used for which could be replaced via a more efficient process • Increased Demand from Excessive System Pressure: Better known as artificial demand Compressed Air Challenge The C.A. System • • • • • • • Demand Side End-Users (Normal Production) Pneumatic tools, cylinders, valves Automation equipment Instrumentation Air Baghouses Blow-off (special cases) Motors/Pumps (where appropriate) Etc. Demand Side Leaks The C.A. System • Higher the system pressure, higher the leak rate – <2 cfm leak: can’t feel, can’t hear – 3-4 cfm leak: can feel, can’t hear – >5 cfm leak: can feel, can hear • Leaks do more than waste energy – Shortens life of supply equipment because of increased runtime – Buy/add new compressor capacity that is not needed • Leak Table for a ‘perfect’ orifice (values are cfm) 70 psig 80 psig 90 psig 100 psig 125 psig 1/64” 0.300 0.335 0.370 0.406 0.494 Compressed Air Challenge 1/32” 1.20 1.34 1.48 1.62 1.98 1/16” 4.79 5.36 5.92 6.49 7.90 1/8” 19.2 21.4 23.8 26.0 31.6 1/4” 76.7 85.7 94.8 104 126 3/8” 173 193 213 234 284 The C.A. System Demand Side Inappropriate Uses • An inappropriate use is anything that compressed air is currently used for, but has a more efficient alternative Potentially Inappropriate Uses Suggested Alternatives/Actions Clean-up, Drying, Process Cooling Low-pressure blowers, electric fans, brooms, nozzles Sparging Low-pressure blowers and mixers Aspirating, Atomizing Low-pressure blowers Padding Low to medium-pressure blowers Vacuum generator Dedicated vacuum pump or central vacuum system Personnel cooling Electric fans Open-tube, compressed air-operated vortex coolers without thermostats Air-to-air heat exchanger or air conditioner, add thermostats to vortex cooler Air motor-driven mixer Electric motor-driven mixer Air-operated diaphragm pumps Proper regulator and speed control; electric pump Idle equipment Put an air-stop valve at the compressed air inlet Abandoned equipment Disconnect air supply to equipment DOE Tip Sheets The C.A. System Demand Side Artificial Demand • If the pressure of the system is too high, uncontrolled uses consume more air – For example, a system that is at 100 psig has a leak load of 100 cfm. If the pressure is decreased, the leak rate is also decreased. – An unregulated air cylinder • Reducing the pressure not only saves energy because the compressor doesn’t have to work as hard, it also reduces the amount of air it has to generate The C.A. System Measurements and Baselining • Compressed air systems are dynamic, meaning that a spot check is not sufficient to determine how well it is operating • Determining how a compressor is operating requires logging equipment C.A. CONTROL STRATEGIES C.A. Control Strategies On/Off Control • The simplest and most efficient control method • Turn compressor on and low pressure setpoint and turn off at high pressure setpoint • Only practical for small motors C.A. Control Strategies Load/Unload Control • Compressor operates in a pressure dead-band, similar to on/off • At upper band, instead of shutting off, compressor “unloads” • Bleed off air/oil separator (~40 seconds) – Only bleed down to ~40 psi – Why does it take 40 second to bleed sump? • Wait for pressure to reach lower setpoint • Compress air/oil separator back to operating pressure (~6 seconds) • Resume operation C.A. Control Strategies Loaded Unloading Unloaded Credit: Ponna Pneumatic Lubricant-Injected Rotary Screw Load/Unload Control Compressed Air/Oil Mixture Oil (Lubricant) “Oil-Free” Compressed Air (2-3 ppm) C.A. Control Strategies Loaded Loading Unloaded Credit: Ponna Pneumatic Lubricant-Injected Rotary Screw Load/Unload Control Compressed Air/Oil Mixture Oil (Lubricant) “Oil-Free” Compressed Air (2-3 ppm) C.A. Control Strategies Lubricant-Injected Rotary Screw Load/Unload Control • Storage plays a huge role in load/unload power consumption C.A. Control Strategies Compressed Air Challenge Load/Unload Control C.A. Control Strategies Modulating Control • A low and high pressure limit as with load/unload • Inlet valve modulates flow rate into compressor – System pressure increases, inlet valve closes – System pressure decreases, inlet valve opens – No blowdown valve, sump always pressurized • Pressure drop across inlet valve – inlet pressure at screws decreases – increases pressure ratio, increases work • Results in competition between savings and costs C.A. Control Strategies Compressed Air Challenge Modulating Control C.A. Control Strategies Variable Speed Control • Add variable speed drive to motor • Speed is proportional to capacity – So at 80% speed, you produce roughly 80% of the rated capacity • Less efficient than other types at 100% capacity – VFD drive consumes some power – Screws on constant speed machines can be designed for a single speed. Screws on variable speed machines must pick a design point, typically about 80% of full speed. Compressed Air Challenge C.A. Control Strategies Compressed Air Challenge Variable Speed Control C.A. ENERGY SAVINGS 55 C.A. Energy Savings Fix Compressed Air Leaks • Compressed air leaks can be between 5 and 30% of system energy usage – Typically 20-30% for ‘unmanaged’ systems – Poorly maintained plants can be even more! • Savings depend on type of compressor and control type, but applicable for all compressed air systems C.A. Energy Savings Fix Compressed Air Leaks • At $0.10/kWh, 8,760 hrs/yr • For a variable speed compressor: Leak Diameter, D (in) 1/32 1/16 1/8 1/4 Volumetric Flow Rate, Vf (cfm) 1.0 4.0 16.1 64.6 Power Loss L (hp) 0.22 0.88 3.53 14.11 Demand Reduction, DR (kW) 0.16 0.66 2.63 10.53 Energy Savings (kWh/yr) 727 2,908 11,634 46,535 Cost Savings ($/yr) $72 $291 $1,163 $4,654 Leak Diameter, D (in) 1/32 1/16 1/8 1/4 Volumetric Flow Rate, Vf (cfm) 1.0 4.0 16.1 64.6 Power Loss L (hp) 0.22 0.88 3.53 14.11 Demand Reduction, DR (kW) 0.048 0.198 0.789 3.16 Energy Savings (kWh/yr) 218 872 3,490 13,961 Cost Savings ($/yr) $22 $87 $349 $1,396 • For a modulating compressor: • Ex: Reduce air leaks by 160 cfm, save $3,458/yr C.A. Energy Savings Reduce Compressor Pressure • Pressure typically set at whatever compressor is rated • Plant rarely needs that high of a pressure • Pressure should be set based on highest pressure need – If the highest pressure need is 65 psig for a process line, then the compressor should be set at a pressure to provide that 65 psig – <100 psi is a typical header pressure • Rule of Thumb: 1% for every 2 psi reduction • Recall discussion about artificial demand • Example: Can we decrease pressure with system “as-is?” – No, already below critical pressure at high demand! – Then modify the system C.A. Energy Savings Change Control Type/Setpoint • Screw compressors can switch from modulating to load/unload very easily* – *Many compressors can do it at the flip of a switch, not all – Storage is important (next slide) • Difficult to retrofit from single speed to variable speed – Typically have to buy new compressor, even more pricy • Interlink multiple compressors with network controls – Typically only useful for many compressor systems – Not as helpful in our example • Overlapping control bands – With pressure fixed, control bands can be separated C.A. Energy Savings Add Storage • Only for load/unload • Adding storage allows for compressor to run unloaded for longer periods of time, resulting in lower overall energy usage • Storage is expensive – $20,000 or more for 7,000 gal of storage • What does 7,000 gallons look like? • What does 20,000 gallons look like? • Add 4,000 gal of storage to system – Switch to Load/Unload – Lower control bands to appropriate points (18 psi improvement) – Savings of $22,226/yr (this includes load/unload savings, pressure reduction savings and overlapping control band savings) C.A. Energy Savings Cool Compressor Inlet • Cooling the air at the compressor inlet reduces energy consumption • Doesn’t work for flooded-oil screw compressors • Works well for reciprocating, centrifugal and oil-free rotary screw compressors C.A. Energy Savings High Volume, Intermittent Needs • Baghouse pulse causes severe pressure drops in system • 6 cubic foot pulse for 0.25 seconds every 1 minute • Instantaneous Flow: – (6 ft3)/(.25 sec)x(60 sec/min) = 1,440 cfm • Average Flow – (6 ft3)/(2 minutes)=6 cfm • Add secondary storage • Savings are hard to figure, likely from productivity increase C.A. Energy Savings Low Pressure Blowers • Air Knifes can be replaced with low pressure blowers • Think about an industrial-strength hair blower without the heat • High flow, low pressure C.A. Energy Savings Utilize Compressor Waste Heat • Use the 80-85% of energy wasted as heat – If air cooled, use to heat areas during winter – If water cooled, might be able to utilize for boiler makeup water or other sources • Piping can get very expensive • Low-grade heat, makes it difficult to capture C.A. Energy Savings Off-Hours Compressed Air Use • Facility not operating, still need compressed air • Typically a result of a “dry” sprinkler system • Compressed air pressurizes and fills pipes, if a sprinkler head bursts the compressed air escapes and the water follows behind • Typically need <5 hp to keep system pressurized • Many companies run one compressor off-shift to pressurize system • Savings for our example are $14,400/yr! C.A. Energy Savings Total Savings from Example • Savings are intertwined; cannot add savings from other slides all together because effects are cumulative • Summary – – – – – Eliminate Compressed Air Leaks Reduce Pressure and Fix Control Bands Add storage and switch to Load/Unload Add low pressure blower for air knifes Add new 5 hp compressor for sprinkler system • Total savings: $66,331 or 65%! • Implementation cost likely below $30,000 • Doesn’t include Productivity Increase! QUESTIONS??? 67