Quality

advertisement

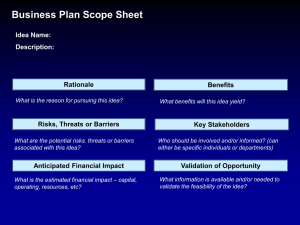

Radiopharmaceutical Production Quality Assurance and a Quality Management System STOP Quality Assurance • • The assurance of quality in products is considered to be a prime responsibility of facility management. Radiopharmaceuticals are pharmaceutical products and therefore, must be manufactured according to the guidelines of Good Manufacturing Practices (GMP) which requires the manufacturing and testing of products in a specified and controlled manner ensuring the application of validated processes and procedures. While the GMP guidelines are the basis for manufacturing radiopharmaceuticals, the management of quality in the finished product and integration of the internal policies and procedures of the organization are achieved through a well-defined and executed quality management system (QMS). Contents • • • • Quality Assurance Quality Management System Validation and Monitoring Documentation See the IAEA publication “Strategies for Clinical Implementation and Quality Management of PET Tracers” To see an article about quality management in commercial FDG production GO HERE STOP Quality Assurance Radiopharmaceutical Production • Testing the product for quality is only one aspect of overall quality management. More significant is the management of quality which comprises of not only quality testing, but also the overall quality assurance and GMP practiced at the production facility. Detailed discussion on these subjects can be found in published literature, including the IAEA publication in this series [TRS 471 Radionuclide Production with a Cyclotron: Facility Planning]. More TRS 471 • Quality assurance is a measure of overall performance of the manufacturing facility, and hence, encompasses a much wider scope and has greater implications. In this context, QA is a sum-total of all activities that individually or collectively influence the quality of the product. It is to be noted that the Good Manufacturing Practices is an integral component of the QA. Unlike the conventional pharmaceutical products, radiopharmaceuticals necessitate special handling during their manufacturing, owing mainly to the short half-lives of the incorporated radionuclides, aseptic processing, parametric release of the product batch, and the radiation protection requirements. Therefore, attention in detail and adherence to the GMP protocols is highly important in assurance of product quality. Quality Management Contents Quality Assurance Quality Management System Validation and Monitoring Documentation STOP Quality Management Radiopharmaceutical Production Quality Management Contents Quality Assurance Quality Management System Validation and Monitoring Documentation STOP The basic elements of quality management according to the WHO are: • An appropriate infrastructure or “quality system”, encompassing the organizational structure, procedures, processes, and resources; and systematic actions necessary to ensure adequate confidence that a product (or service) will satisfy given requirements for quality. • There is often confusion about what documents should be in place to ensure that a working quality assurance program is in place and that demonstrate to an inspector that all aspects of quality assurance have been addressed. • One approach to this documentation which has been used successfully for the establishment of a program uses three documents to delineate different aspects of the program. The documents required are: – Site Master File – Quality Manual – Validation Master Plan Radiopharmaceutical Production • Quality Management Contents Quality Assurance Quality Management System Validation and Monitoring Documentation • STOP Quality Management Each of these documents has a specific purpose and taken together, give a clear picture of the facility purpose, the quality plan for the facility and how the validation of this quality plan will take place. – The Site Master File (SMF) should contain specific information about the quality management policies and activities of the company, the production and/or quality control of pharmaceutical manufacturing operations – The facility’s Quality Manual (QM) should outline which regulations are going to be followed, how they are going to be followed, who is responsible for ensuring that the regulations are followed, and which of the companies approved procedures address the regulations to be followed. – The Validation Master Plan (VMP) documents the way the company will operate, who has control over the various aspects of the validation activities, and how production, quality control, and personnel management will be directed. As can be seen, there is some overlap in the contents. As long as all aspects are addressed, the exact division is up to the facility management. Quality Management Radiopharmaceutical Production • Quality Management • Contents Quality Assurance Quality Management In the following slides, there is a description of the development of a quality system starting with a quality manual and going down to specific procedures and tests. Information about the Site Master can be found by following the arrow More Site Master File System Validation and Monitoring Documentation • The Validation Master Plan is a separate document that covers all aspects of validation for the facility. There is a entire section on this document which can be found by following the arrow. More STOP Validation Master Plan Quality Management System Radiopharmaceutical Production Quality Management Contents A quality management system can be thought of as a process where we start with a philosophy of quality when then flows down into specific steps and instructions which ensure that the product being produced is always safe and effective. It involves the other documents related to quality as well. Quality Assurance Quality Management System Validation and Monitoring Documentation Validation Master Plan Site Master File Quality Manual Job responsibilities and authorities Operating Instructions Reports STOP Standard Operating Procedures Completed Batch Records Tables Quality Management System Radiopharmaceutical Production Quality Management Contents Quality Assurance Quality Management System Validation and Monitoring Documentation More Information can be obtained on each of these topics by clicking on the appropriate box The first step in the development of a management system is the production of a quality manual. This manual comes before the Validation Master Plan and other Quality documents Manual Job responsibilities and authorities Operating Instructions Reports STOP Standard Operating Procedures Completed Batch Records Tables Quality Management System Radiopharmaceutical Production More Information can be obtained on each of these topics by clicking on the appropriate box Quality Management Contents Quality Assurance Quality Management System Validation and Monitoring Documentation The next step is to apply the principles stated in the quality manual and assign job responsibilities and authorities Quality Manual Job responsibilities and authorities Operating Instructions Reports STOP Standard Operating Procedures Completed Batch Records Tables Quality Management System Radiopharmaceutical Production More Information can be obtained on each of these topics by clicking on the appropriate box Quality Management Contents Quality Assurance Quality Management System Validation and Monitoring Documentation The next step is to have knowledgeable people develop operating instructions for all the equipment Quality Manual Job responsibilities and authorities Operating Instructions Reports STOP Standard Operating Procedures (SOPs) must be developed for every operation related to the manufacture of the radiopharmaceutical Standard Operating Procedures Completed Batch Records Tables Quality Management System Radiopharmaceutical Production More Information can be obtained on each of these topics by clicking on the appropriate box It also includes the completed batch records for all the product made at the facility Quality Management Contents Quality Assurance Quality Management System Validation and Monitoring Documentation The operating instructions and the SOPs lead to the documentation of all the work that goes on Quality in the facility. This Manual includes the reports on the equipment Job responsibilities validation and and authorities calibration Operating Instructions Reports STOP There are also tables of results so that trends may be established and a operational matrix which ensures that all the personnel are currently trained to perform their assigned functions Standard Operating Procedures Completed Batch Records Tables Quality Management System Radiopharmaceutical Production Quality Management Contents Quality Assurance More Information can be obtained on each of these topics by clicking on the appropriate box Quality Management System Validation and Monitoring Quality Manual Documentation Job responsibilities and authorities Operating Instructions Reports STOP Standard Operating Procedures Completed Batch Records Tables Validation and Monitoring Radiopharmaceutical Production • Quality Management Contents Quality Assurance Quality Management System Validation and Monitoring Documentation • • STOP Key features of the quality assurance program are that the tests are performed with well-established protocols (the standard operating procedures, SOPs), and the results are presented with maximum confidence. All quality test procedures, therefore, should be developed, tested, and fine-tuned (validation) prior to putting into practice for testing FDG batches. Monitoring of the test results ensures the continued suitability of the validated processes. More on Process Validation can be found by following the MORE arrow More Process Validation More on Equipment Validation can be found by following the MORE arrow More Equipment Validation Documentation Radiopharmaceutical Production Quality Management Contents Quality Assurance Quality Management • Good documentation is one of the keys to a good quality assurance program. Each piece of critical equipment must be validated , each process must be clearly delineated and each production run must be documented. These records must be kept according to strict guidelines. Examples of these guidelines can be found in the section on documentation by following the arrows System Validation and Monitoring Documentation STOP More Documentation Return to Main Menu