Mini Project Documentation

advertisement

Mini Project Documentation:

Bacterial Growth Monitor

MTI FALL 2010

By: Rohan Sharma

Concept Development/Background:

The idea for the use of my device came about from a recent

experiment we did in Bio Lab

Basic idea of experiment was to insert a gene (luciferase) into a

strain of bacteria (E. coli) in order to allow them to glow in the

dark

Students were asked to take plates of the mutated bacteria home

and record the time they initially displayed luminescent properties

The problem: this process can take anywhere from 48-96 hrs(!)

Since it wasn’t realistic to expect students to simply sit around and

stare at their cultures and wait for them to glow during this

period, all of the students’ recorded times became rough

estimates, resulting in less accurate experiment documentation…

The Solution:

A device which could sense precisely when

the bacteria began to glow + trigger a

mechanism that would alert the student

Instructions for use:

Simply put the test tube containing bacteria into box and wait!

Basic Breakdown of how it works:

START: Photocell detects brightness of Bacterial Culture (or LED controlled by

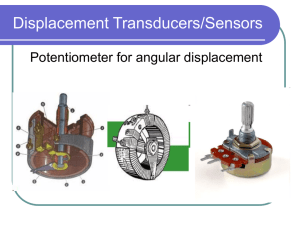

Potentiometer)

DC Motor was programmed to switch on after photocell detected certain

threshold

Mechanism was attached to DC Motor to convert rotational motion to linear

motion

Wooden stick travelling in linear motion rings alarm/bell/wakes up student

through poking

FINISH: Student knows exact time culture is ready

Critical

Components:

-Arduino + Breadboard + USB Cable

-Box or vessel to hold test tube of bacteria

(must be closed to prevent external light from

entering and invalidating results)

-Photocell

-DC Motor + H-bridge

-Mechanism for converting rotational motion

into linear motion

-(For demonstration purposes) an LED +

Potentiometer to simulate when the bacterial

culture was dark and when it reached a certain

brightness

-Resistors

-Wires

Other Materials That

Were Used:

-Electrical Tape

-Wood Glue

-Plastic Lid

-Paint

-X-acto Knife

-Paperclips

-Velcro Stickers

-Wooden Sticks

Building Instructions:

1.Once you have all the critical components, a hole must be cut out of the

back of the box in order to connect the USB port. Other smaller holes

must be cut into the front of the box to allow motor and potentiometer

wires to be attached. The last holes I made were used to put 2 small

wooden sticks through the sides of the box in order to prop up the

breadboard (see side view)

2.Next, I cut out two ‘arms’ out of cardboard, and glued them to both

sides. Then, after poking a wooden stick at the end of both arms to

support mechanism later, I glued a paperclip to the end of the stick

whose side the mechanism would later be attached to. This was done in

order to prevent stick from sliding off when motor is turned on.

3. The next step was to actually make the mechanism for converting the

rotational motion of the DC motor into a linear motion which could

ring a bell, etc. In order to do this, I used a plastic lid and simply cut a

hole at its center. A wooden stick was then attached to the edge of the

plastic container by inserting a paper clip through both. This was crucial

for allowing free rotation of the wooden stick. The end of the paper clip

was then bent in order to prevent the stick from falling off.

Building Instructions (cont’d):

4. After this, I attached the plastic lid onto motor simply by

sticking end of motor through the hole I had cut. Next, I

used Velcro stickers to attach the DC motor to the box.

The same method was used to attach the potentiometer

to the front of the box as well.

5. I then cut the box open along 3 edges and unfolded them

slightly. The Arduino attached to breadboard was then

placed inside (refer to following slide for wiring

schematic), using the two wooden sticks as support.

Next, I plugged in USB port through back and taped

edges of box back together.

6. Lastly, I turned on potentiometer to watch the motor

run!

Wiring Schematic:

Here is what the Arduino +

Breadboard looks like before

being placed inside box:

Programming Code:

int motorPin1 = 8; // left motor pin wired to Digital Pin 8

int motorPin2 = 7; // Right motor pin wired to Digital Pin 7

int photosensor = A1; //Photocell hooked up to Analog Pin 1

int ledpin = 13; // LED connected to Digital Pin 13

int sensorValue = 0; // initial sensor value

int potPin = A3; //Potentiometer wired to Analog Pin 3

int potentiometerValue = 0; //Initial Potentiometer Value set to 0

void setup()

{

Serial.begin(9600);

pinMode(photosensor, INPUT); //declares Photocell as Input

pinMode(motorPin1, OUTPUT); //declares left motor pin as Output

pinMode(motorPin2, OUTPUT); //declares right motor pin as Output

pinMode(13, OUTPUT); //declares LED as Output

}

void loop() {

int brightness = analogRead(photosensor); // defines photocell output as a function of LED brightness

int speed = map(brightness, 0, 400, 125, 255); //defines motor as a function of photocell output + maps output values

analogWrite(motorPin1, speed);

analogWrite(motorPin2, 0); //allows only the left motor pin to rotate , corresponding to photocell output

digitalWrite(13, HIGH); // sets LED to ON position as default

potValue = analogRead(3); // defines potentiometer value as value coming from Analog Pin 3

analogWrite(13, potValue/4); //Made LED dependant on potentiometer value (value was divided by 4 to allow to fit into byte)

speed = constrain(photosensor, 0, 100); // constrains motor to run on photocell output of ’20’ or higher

Serial.println(analogRead(photosensor)); // prints current output of photocell

}

Biggest Problems Encountered:

-Initially light from Arduino board kept setting off motor when

placed inside box, so electrical tape was used to cover up

these lights

-Putting all the components inside the box was too difficult, so

edges had to be cut and folded back to allow more room to

work, then later taped back

-Calibrating the photocell to produce an OUTPUT value that

was low enough to detect an LED when it was switched on

by the potentiometer, but high enough not to have the motor

be set off too easily, required some playing around with the

‘map’ and ‘constrain’ functions; eventually a value of ‘20’ was

found to work

Possible Improvements/Future Ideas to

Play Around With:

Have speed of motor correspond to brightness/number of

luminescent bacterial cells

Wire LED’s to outside of box and program to brighten or

dim in relation to culture growth

Have sensor output send wireless signal as text message or

email when cultures are ready