Managerial Design Review Presentation

advertisement

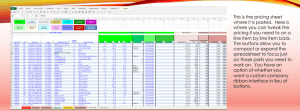

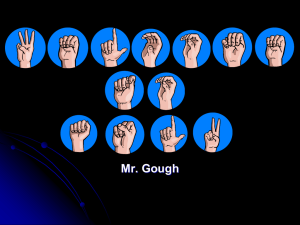

P11032 NTID Wireless Presentation Control Steve Fleischmann, Evan McNamara, Artem Sivak, Mason Verbridge Introduction GOAL: Design and construct a "proof-of-concept" solution which made delivering PowerPoint presentations easier and more effective for users of ASL. •Majority of our resources were devoted to prototyping and demonstrating our wrist-based "proofof-concept" solution. •In parallel, both the electrical and mechanical designs were analyzed with respect to manufacturability. Background • Wrist-based wireless PowerPoint control device is not currently available from any retailer in the industry. • Design was based on making the device comfortable, functional, and aesthetically acceptable • Initial set of users for our device consists of mainly students, professors, and interpreters within RIT NTID who utilize ASL. • End users and customer needs drove formation of engineering specs Background Design Process Concept Selection: -10 concepts were generated using multiple brainstorming mechanisms. -King of the Hill conversation -Generalized brainstorming -Morphological charts -Ten concepts were generated Design Process: Concept Generation Initial Selection Table | Narrowed 10 concepts to 5 Using Pugh Chart | Concepts -> HOQ, graded vs. weighted specs | Narrowed to 3 concepts | Analyzed against risks | Current Concept Design Process: Prototype • Important to note: • • • • • • • • • • -Any change in overall device size was at a premium -Height was the most important dimension -Tactile feel of buttons was a must. Modeling started by hand, then progressed to Solid Works As proof of concept, an existing product was modified. -Laser pointer removed -PCB trimmed -Antenna re-routed -On-board buttons removed • • • Primarily done as a work-around for software issues. All pieces were machined/modified/ aligned as necessary. Prototype was assembled! Testing A combination of direct testing and user feedback was used to gauge the device’s performance. Equipment used: - Windows PC with Microsoft PowerPoint 2003 or later found on a laptop provided by the team - Digital Scale obtained from the Aero Club - PC-Connected Projector obtained from Mark Smith - Projector Screen found in Erdle Commons in Building 09 - Calipers provided by Mason - Digital Multimeter found on the 3rd floor in one of the Electrical Engineering Labs - Stopwatch Program on Mason's iPhone - 3DSSPP Software found in the ISE Computer Labs Tests 1. Device will be under 0.5 pound(s). The complete device (including the band) will be weighted on a digital scale with .01 accuracy. The device must weigh less than 0.5 lb. 2. Device will allow full range of natural motion, including excessive hand motion and roaming the presentation area. (No wires or restrictive components) Based on user feedback. 3. Maximum Size will be less than 24 cubic inches. The casing from the device will be measured by calipers in length, width, and height. The volume of the device has be less than 24 cubic inches. (excluding the band) 4. Device can sustain multiple drops from waist height (~3ft) onto carpeted surface. There will be 3 steps to passing this criteria. First the device will be tested on a computer to show that it is working. Second the device will be dropped 10 times from 3ft on the carpeted floor in Erdle Commons. The device will be released from the hand to replicate accidental drop. Third, the device must work after the 10 drops and will be verified by testing it on a computer. 5. Device will allow ASL to be utilized without major interference. Based on user feedback. 6. Device will not progress to next slide, or return to previous slide, without intentional activation. Based on user feedback. 7. Device will work within a range of minimum of 40 feet from PC without problem. A computer will be place 30ft away from the device. The device must be able to flawlessly scroll a 20 slide presentation to the end and then back. 8. Device will be implemented for minimum cost. The cost of the project will be less then the allowed budget of $750. 9. Battery life will exceed 4 hours of continual usage. Put in a new battery. Set up a laptop. Press the up button and leave it on for four hours. The remote must work after four hours. Pass/Fail 10. Latency between button push and slide change will be less than 0.75s Create a powerpoint with 100 numbered slides. Starting at slide #1, the tester will press the “next slide" button as rapidly as possible. After 60 seconds, the user must reach at least slide #80. By surpassing slide #80 in 60 seconds, the tester will have achieved an average slide change time of .75 seconds or less. 11. Device successfully advances to next and previous slides. The wristband will be used to flip 20 slides to the end and then back at 10 ft away without any trouble. This test will be covered by test 7. 12. The device will be safe to use for as wide of the population as possible. A model will be created in the 3DSSPP software to show that the device does not pose any dangers to joints and muscles. Customer Feedback Description Survey Average (0=Worst, 10=Best) Asthetics 5.4 How does the the device case look How does the band look How does the overall device look Rate how distracting the device was during ASL use 5.8 5.7 5.7 4.6 Comfort 6.7 How comfortable does the device case feel on your wrist How comfortable is the wristband How would rate the over all comfort How comfortable are the buttons 6.5 7.2 6.5 6.7 Fit 7.9 How easy was it to strap the device to your wrist How well does the device fit on your wrist 7.9 7.8 Function 8.5 How well did the device change power point slides How would rate the button pressing How easy was it to use the device 9.2 7.6 8.7 Overall 7.2 Overall, how would you rate this device Up to what amount would you be willing to pay for this 7.2 $25.80 Recurring Comments •Device is too large •Get me a laser pointer •Make the band thinner and more comfortable •Make the buttons smaller (or touch sensitive) •Make the device less visually distracting. Performance High Level Results •Device Range greater than 30ft! •Successfully moves the slides back and forth without false triggers! •Easy and intuitive to use! •Battery life exceeds 4 hours! •Only 0.126lb! Very Light! Safety Because the device only weighs 0.126lb, it’s biomechanically safe to use for an extremely wide range of users. Tested: A 5th percentile female test subject was chosen to represent the lowest possible capability. She passed with an average of 99% capability, showing that the device is biomechanically safe to use for everyone else. Lessons Learned, Suggestions for Future Teams • Mass Production – Rapid Prototype mold for <1000 units, minimize component number/cost • Mechanical – One cover design, Concurrent electrical design, Design with injection molding in mind • Electrical – Antenna, circuit design suggestions, added features, concurrent design with housing Future Work Estimated Production Costs Item Unit Cost Qty Needed Mold With Rapid Prototype Insert Plastic Pellets $1,500.00 1 Cost Calculation $1,500.00 $0.05 1000 $50.00 $0.50 1000 $500.00 $0.05 1000 $46.67 $10.14 1000 $10,140.00 (per part) Aluminum Housing Cover Laser Cut 2-56 Flush Mount Screws Electrical Components (per part) Wristband (per part) Total Cost for 1,000 Units Cost Per Unit Mechanical Improvements • Injection molding allows for more intricate, smaller housing • Design the custom board footprint to be easily packaged • Package the board such that all components can be surface mounted Electrical Improvements $3.00 1000 $3,000.00 $15,236.67 $15.24 • • Utilize a embedded RF antenna Custom transmitter / receiver chips could drastically increase range Where should they start?!? The first major challenge in mass producing this part would be creating and/or legally purchasing a USB dongle and software to interface with the computer