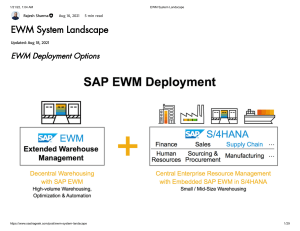

SAP EWM with W2MO: Warehouse Optimization & Simulation

advertisement

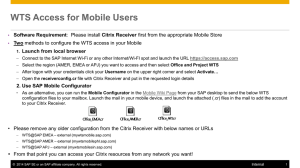

SAP EWM with W2MO SAP EWM with W2MO What is my pain? Limited visualization of warehouses Little options for simulations Problems measuring the impact of adjustments in EWM Difficult to identify bottlenecks in warehouses Unintuitive labor management What are my needs? 3D visualization Simulation of future scenarios Comparison of different strategies Identify workload & bottlenecks in 3D view Easy to use labor management 2 W2MO 3D Warehouse visualization 3D Simulation 3D Workload visualization Staff capacity planning Warehouse design optimization Case Pack optimization 3 W2MO Goal W2MO is to: • • • • Automate Optimize Facilitate Accelerate Create the optimal layout & processes! 4 W2MO Fast efficiency increase by… • Comparison of different picking strategies and automation levels • Optimized rack setting • Fast creation of future scenerios • Scenario planning • Calculation of labor efforts & costs • Visualize dynamic and time-specific bottlenecks • Optimized workload balancing • Case Pack optimization 5 SAP Connector SAP EWM SAP Connector W2MO Storage types Bins Bin types Products Fixed bins Tasks/Orders Etc. 6 SAP EWM with W2MO Implement new settings in EWM Create WTs Discuss and decide for new EWM settings Transfer of WTs & strategies to W2MO Analyze in W2MO 7 SAP EWM with W2MO: Example Definition/Scope Semi-automatic SAP EWM warehouse Picking/Putaway strategies Measurement Create WTs and transfer to W2MO Evaluation of labor costs for the current processes Analysis Analysis of the EWM strategies Simulation with adjustments to parameters Enhancement Adjustment of the limits for pick & pack Calculation of labor costs for optimized process Performance was enhanced by 22% Performance + 22% Control Continuous performance monitoring 8 W2MO with EWM: benefits • 3D visualization • 3D simulation • 3D workload planning • Staff capacity planning and optimization • Optimize your logistical processes • Optimalize EWM parameters, such as waves, queue and slotting strategies • Measure and enhance warehouse performance • Slotting and optimized product allocation • Picking route optimization 9 W2MO with EWM Reference Schukat electronic: • Optimized product allocation -5,5% picking hours / -4,7% picking travel distance • Optimized product allocation + number of orders assigned per resource -8,7% picking hours / -14% picking travel distance • Number of orders assigned + volume allowed per resource -8,5% picking hours • Analysis of order structure, staging zones, processing of single items -13,3% picking hours 10 For more information Managing Director Rogier Post +31 (0)652569705 rogier.post@insidescm.com Managing Partner Joachim van Goch +31 (0)645945759 joachim.van.goch@insidescm.com Website www.insidescm.eu 11