Project Report - Lean Sigma

advertisement

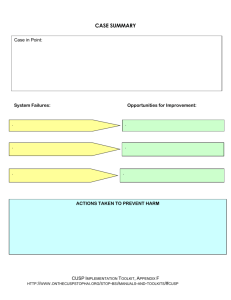

On the CUSP: Stop BSI The Comprehensive Unit-based Safety Program (CUSP) © 2010 The Vision of CUSP The Comprehensive Unit-based Safety Program is a safety culture program designed to: – educate and improve awareness about patient safety and quality of care – empower staff to take charge and improve safety in their work place – partner units with a hospital executive to improve organizational culture and provide resources for unit improvement efforts – provide tools to investigate and learn from defects © 2010 CUSP: 5 Steps 1. Educate staff on science of safety 2. Identify defects 3. Assign executive to adopt unit 4. Learn from one defect per quarter 5. Implement teamwork tools Pronovost J, Patient Safety, 2005 CUSP Toolkit, http://www.safercare.net/OTCSBSI/Resources.html © 2010 Working the Steps in CUSP One Cycle of CUSP From Start to Finish: A Telemetry Unit © 2010 Step 1: Educate • All staff were educated on the Science of Safety – Included nurses, technicians, clerical associates, and housekeeping. • All physicians are educated upon hire • All nurses are educated upon hire. © 2010 Step 2: Identify Defects All staff were asked to complete the Staff Safety Assessment (Appendix C) © 2010 Step 3: Executive Adopts a Unit • The VP of Security and Parking is the executive for this unit. • The Executive along with the CUSP team reviewed the Staff Safety Assessment to identify select a defect to work on and learn from. © 2010 Staff Safety Assessment Results N=24* *2 answered unit is safe © 2010 Staff Safety Assessment Results • Staff had many ideas about how to reduce the falls on this unit. 23 interventions involving: • Bed • Side rails • Patient • Environment • Education • Process changes • Communication © 2010 Step 4: Learning from Defects The next CUSP meeting the team started the Learning from Defects tool (Appendix G). © 2010 Step 4: Learning from Defects • To answer section I the team needed to understand if there were any common themes/risk factors related to the falls on this unit. • Reviewed 12 months of fall data: – 90% of falls occurred on night shift, within 1 hour of change of shift, and on weekends – Nurses reported they had forgotten to turn bed alarm back on after giving care. – Less nurses/staff around seemed to predict increased risk for fall or day shift could compensate for bed alarms off when they had more staff around © 2010 Step 4: Learning from Defects n/a n/a © 2010 Step 4: Learning from Defects Team factor- adequate communication during care w/ ancillary staff 5 5 Caregiver factor- distractions lead to patients bed alarm not turned on 5 5 © 2010 Step 4: Learning from Defects Independent double check for bed alarms Add column to report sheet for patients with high fall risk Every 4 hours staff will check Hill-Rom system to ensure bed alarms are on © 2010 5 5 5 4 Step 4: Learning from Defects Add column to report sheet to communicate high fall risk to ancillary staff Rosemary Develop checklist to allow staff to document that bed alarm on every 4 hours* Stacey *Timed with shift change- 02:00, 06:45, 14:45, 18:45, 22:45 - Clerical associate responsible for checking at all times except 02:00 - Charge RN responsible for 02:00 check © 2010 9/15/09 9/15/09 Step 4: Learning from Defects © 2010 Engage & Educate Started engaging and educating staff as soon as falls identified as defect to work on for CUSP project. © 2010 NDNQI 10th Percentile © 2010 NDNQI Median Fall Rate (Falls per 1000 patient days) Apr-10 Mar-10 Execute: Independent Double Check on Bed Alarms Engage & Educate Feb-10 Jan-10 Dec-09 Nov-09 Oct-09 6 Sep-09 7 Aug-09 8 Jul-09 9 Jun-09 May-09 Apr-09 Mar-09 Feb-09 Jan-09 Dec-08 Nov-08 Oct-08 Sep-08 Aug-08 Jul-08 Jun-08 May-08 Apr-08 Mar-08 Feb-08 Jan-08 Dec-07 Nov-07 Oct-07 Sep-07 Aug-07 Jul-07 Falls per 1,000 Patient Days Step 4: Learning from Defects Fall Rate 10 Evaluate 5 4 3 2 1 0 Step 4: Learning from Defects Evaluate: • 7 months prior to intervention Mean - 2.85 falls per 1,000 patient days • 7 months since the intervention Mean - 1.33 falls per 1,000 patient days • 50% reduction in falls • Extremely low burden intervention © 2010 Examples of CUSP in Action!!! © 2010 Identified concern from Staff Safety Assessment (CUSP Step 2) Recommended Improvements (CUSP Step 4 & 5) Interventions Implemented Risk of central line associated bloodstream infections Make sure best practices are used for all central lines insertions. A line cart and checklist is used for all central lines insertions. Risk of central line associated bloodstream infections due to poor compliance with IV tubing changes Make sure every central line IV tubing is changed according to best practice. New IV tubing labeling system used. Risk of medication errors Point of care pharmacist available on units Pharmacist assigned Poor management of pain Create guideline or protocol for pain assessment and management Pain card at every bedside Poor communication among ICU providers Create Short Term Goals Sheet Short term goals sheet used during rounds Poor communication during ICU discharge leading to medication errors in transfer orders Implement medication reconciliation process at ICU discharge Medication reconciliation done at discharge CUSP is a Continuous Journey • CUSP is a marathon not a sprint • Ask staff at least every six months how the next patient is going to be harmed and invest the time and resources to reduce this harm • Learn from one defect per quarter and share lessons learned • Implement teamwork tools that best meet the teams needs © 2010