Anatomy of A Bridge - Engineering program at Albany State University

advertisement

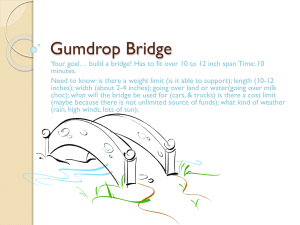

Anatomy of A Bridge Anatomy of A Bridge Atin Sinha, Ph.D., P.E. Albany State University Atin Sinha, Ph.D., P.E. Albany State University Different Types of Bridges Truss Bridge Suspension Bridge Cable Stayed Bridge Truss Bridge Truss Bridge Suspension Bridge Suspension Bridge Cable Stayed Bridge Cable Stayed Bridge Loads Experienced by A Bridge Static (Structural) Variable (Vehicular Traffic, Pedestrian) Environmental (Wind, Earthquake) Forces that Act on Bridges Tension Compression Torsion Shear Suspension vs. Cable Stayed Common Trusses Used in Engineering: Warren Pratt Howe K Truss Red represents tension, blue represents compression, and green is no load Now examine the same Warren truss, but with added vertical members Model Bridge Building Steps Learn the Rules of the Competition Design the Bridge Get the Supplies Build the Bridge Test the Bridge Analyze the Failure Improve Your Design Southwest Georgia Regional Model Bridge Building Contest Design Specifications for the Model Bridge Span 22 in. Maximum Allowable Weight 28.3 g Maximum Allowable Height (Overall) 10 in Max Superstructure Height 6 in Max Substructure Height 4 in Minimum vertical clearance through the bridge 2 in Minimum horizontal clearance through the bridge 2 in No height restriction for Middle Schools Design the Bridge Center the design around the loading point Provide extra bracing around the loading point Choose a truss Warren, Pratt or design your own Draw the bridge to scale on graph paper Create a list of all the pieces Cut the pieces to exact size Label and weight every piece Allow 10% weight for glue If you exceed the weight limit, modify the design Preparation for Building the Bridge Get the wood Hobby stores Specialized Balsa.com Pick out the “good” wood Tools Glue Saw/Exacto knife Gram scale Clamps/clothespins Foam Board (optional) Workspace Good lighting Good ventilation Build the Bridge Tape the top and bottom beams to the design on the graph paper Glue the remaining pieces and cure overnight holding firmly using pins. After both trusses are completed, tape them to two fixed boxes spaced correctly apart Glue bracing on top and bottom Make sure the bridge is not leaning on one side Weigh the bridge and record including the specs Test the Bridge Test before competition if: Testing equipment You have time to build another bridge You are only testing your bridge to a certain point Bathroom scale (top loaded only) Bucket and sand (top or bottom) Testing procedure Pour the sand slowly but steadily Watch for deflection ( 2” is considered failure) Evaluation of the Bridge Efficiency = mass that bridge held divided by mass of bridge What failed (Broken member / joints unglued) ? In order to win typically score need to be well above 250 Video taping Careful examination of broken pieces Improving Design (Add a piece where it failed) Construction (add notched joint / gusset plate) Winners From the Past Years Year Bridge Weight (gm) Breaking Load (gm) Structural Efficiency 2003 2004 2005 28.1 25.6 22.8 10276 5789 10197 365.7 226.1 447 2006 17.5 9488 542 2007 23.7 13253 559 2008 28.1 11114 396 2009 22.7 5930 261