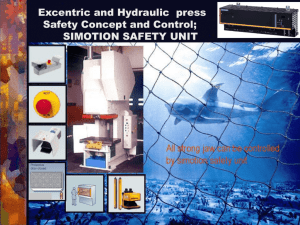

guards-devices-presentation

advertisement

Guards Prevent Access If Infeasible Devices Control Access 1 Requirements of Safeguards Prevent contact Secure Protect from falling objects Create no new hazards Create no interference Allow safe lubrication 2 Where Mechanical Hazards Occur Point of operation Power transmission apparatus Other moving parts – Nip points – Pinch points – Shear points – Rotating parts – Flying parts 3 Training Description and identification of hazards How they provide protection How to use safe guards When to remove Protocol when safeguards are missing 4 Methods of Guarding Guards Devices Location/distance Feed mechanisms Miscellaneous aids 5 Guards Barrier to prevent access to danger Fixed guards Interlocks Adjustable Self-adjusting Stock Exit Stock entering danger zone Transparent insert in front panel 6 Fixed Frame Panel 7 Box Barrier Guard without Inserts 8 Adjustable Panels Rigid - Adjustable Fixed - Adjustable 9 Two and Four Panel Barrier Guard Not considered a safeguard. Are used with safeguarding devices such as two-hand trips, presence sensing devices, pullback, or restraints. Designed to protect sides of the point of operation while the front is open for feeding and removing of pieceparts. 10 Three and Five Panel Barrier Guard Are designed to meet point-of-operation requirements. Rear of machine must also be guarded when applying front and side guards. 11 Interlock Safety Switches 12 Devices Presence-Sensing Radiofrequency Electromechanical sensing device Pullbacks Restraints Safety Trip Controls Two-Hand Controls Two-Hand Trip Gates 13 Presence Sensing Device Transmitters Receivers Control Box Interconnecting Cables 14 Arm-Type Device Arms 15 Arm-Type Pullback Pullbacks 16 Overhead-Type Pullback 17 Restraint Device - Arm-Type Restraint 18 Two-Person Overhead Sliding Restraint 19 Control Package with Light Curtain Interface or Two-Hand Control Control Box Light Curtains on Floor Stands Two Operator Stations Barriers 20 Press brake with two-hand control sequence Emergency Stop Two-hand Controls 21 Gate Guards - Type “A” and“B” 22 Location/Distance Hazard analysis Hazards not accessible Walls Fences Height Stock dimension Operators station 23 Press Safety Distances Distance of Opening from Point of Operation Hazard (inches) Maximum width of opening (inches) 1/2 to 1-1/2 1-1/2 to 2-1/2 2-1/2 to 3-1/2 3-1/2 to 5-1/2 5-1/2 to 6-1/2 6-1/2 to 7-1/2 7-1/2 to 12-1/2 12-/12 to 15-1/2 15-1/2 to 17-1/2 17-1/2 to 31-1/2 1/4 3/8 1/2 5/8 3/4 7/8 1-1/4 1-1/2 1-7/8 2-1/8 24 Press Safety Distances (cont’d) Once a safe distance is calculated, note the following to right of press. – Date of measurement – Stopping time – Safe distance calculation – Added distance to allow for normal deterioration – Forward most point of operation – Fixed location of safety device/guard 25 Feeding & Injection Automatic feeding Semi-automatic feed Automatic injection Semi-automatic injection Robots 26 Robot Safeguarding Station Control Guard Machine Safety Mat Light Curtain Receiver Robot Parts Bin Parts Chute Guard Light Curtain Transmitter Mirror 27 Miscellaneous Aids Awareness barriers Shields Holding tools Push stick or block 28 Signs for Machinery OPERATOR SAFETY PRECAUTIONS Handout for Anyone Operating This Machine Before You Operate This Machine You Must Read and Understand These Safety Precaution ! DANGER NEVER Place Your Hands or Any Part of Your Body in This Machine See Reverse Side for Other Safety Precautions. 29 Signs For Machinery ! PELIGRO ARIETE HIDRAULICO Y TROQUEL CIERREN RESULTARA EN LA PERDIDA DE DEDOS O DE MEMBROS SI ESTAN METIDO EN LA MAQUINA NUNCA USW UN PEDAL DE PIE PARA OPERAR ESTA MAQUINA A MENOS QUE SE PROVEE Y MANTIENE UN PROTECTOR DE SEGURIDA PARA EVITAR QUE LAS MANOS U OTRAS PARTES DEL CUERPO ENTREN EN LA MAQUINA. NO SE DEBE QUITAR O TAPAR ESTE LETRERO. VEA L REVES PARA MAS INSTRUCCIONES. 30 Free-Standing shield used around machines to protect people from flying objects 31 Shield on milling machine 32 Sliding Lathe Shield 33 34