Pedestal Grinder

advertisement

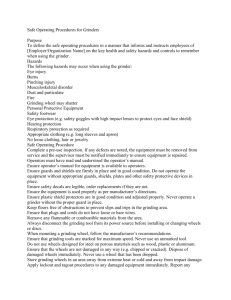

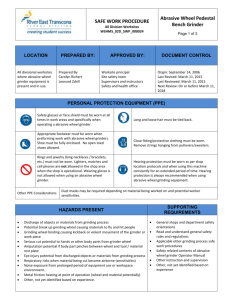

1) Identify the major parts of a pedestal grinder with 80% accuracy. 2) Identify appropriate use of a pedestal grinder and its various wheels and dressing tool with 90% accuracy. 3) Understand and utilize proper safety when using a pedestal grinder with 100% accuracy. Pedestal Grinder Objectives 1) Why is it important to be able to properly differentiate between types of grinding wheels and Wire brush wheels? 2) Why is it important to know the parts of the pedestal grinder? 3) Why is it necessary to apply proper safety techniques when using a pedestal grinder? 4) Why is it important to know how to dress a grinding wheel? Reasons to Learn? 1) What do we need to know in order to differentiate between types of grinding wheels and wire brush wheels? 2) What do we need to know to differentiate between the parts of the pedestal grinder? 3) What do we need to know about the safe operation of the pedestal grinder and its diverse range of uses? 4) What do we need to know about dressing grinding wheels? Questions to Answer We need to know that we have five types of grinding wheel attachments. Grinding Wheels 1) Coarse – multi-purpose good all-around shop performance 2) Very Coarse – more aggressive good for removal of large amounts. 3) Fine – usually used in wet or precision grinding. Wire Brush Wheels 4) Coarse – cut aggressively, are very stiff, and can be dangerous. 5) Fine – less aggressive, less stiff, less danger. Answers to Questions • Pedestal Grinder Parts • • • • • Safety Shield- shield over front of wheel Motor- drives the wheels Adjustable Spark Deflector- deflects sparks Wheel Guard- guards grinding wheel Plane Blade Grinding Attachment- used to grind plane blades • Dust Chute- routes grinding dust away • Pedestal-the stand where the grinder is mounted Answers to Questions • Pedestal Grinder Parts cont. • Switch- powers the unit on and off • Adjustable Tool Rest- adjustable plate where work is rested • Water Pot- filled with water to cool hot metal • Grinding Wheel- abrasive cutting particles formed into a wheel • Wire Wheel- abrasive wires formed into a wheel • Grit- the cutting particles • Face- surface of the wheel intended for use Answers to Questions The proper use of the pedestal grinder is imperative to insure user safety and effectiveness. • Safety glasses must be worn • Wheels that show excessive wear, uneven face, and chips or fractured faces are considered damaged. • All guards must be in place • Tool rests should be properly adjusted before using the pedestal grinder. Answers to Questions • Any tool found to be damaged should be taken out of service and reported to the instructor immediately. • Gloves should be worn. • Small work pieces should be held with lever lock pliers. • Adjust the tool rest so its top surface is level with the center of the motor shaft and within 1/16 in. of the wheel. • For bevel grinding, set the tool rest at the appropriate angle. Answers to Questions • All work must be firmly held on tool rest. • Move the metal back and forth or in a curved motion as needed. The movement will help keep the stone clean and avoid overheating of the metal. • Caution! Do not use excessive pressure on the metal. Answers to Questions Different situations call for different wheel selection. • Coarse or very coarse wheels are designed for multipurpose application. • Wire brush wheels are useful for removing rust, dirt, paint, gasket materials, slag etc. Answers to Questions • Dressing Grinding Wheels • Removes material, rounds out the face square to the sides. • Exposes sharp abrasive particles. • Removes clogged abrasives and slight bulges that cause the wheel to get out of balance. Answers to Questions • Dressing Grinding Wheels • Safety glasses must be worn. • Obtain a wheel-type grinding wheel dresser. • Power up the grinder. • Place the dresser on the tool rest of the grinder. • Slowly rock the dresser wheels forward until they touch the grinding wheel. Answers to Questions • Dressing Grinding Wheels • Apply firm and even pressure on the dresser and move it back and forth across the wheel for about 30 sec. • Remove the dresser and power the grinder down. • Re-adjust the tool rest to within 1/16 in. of the wheel. Rotate wheel and check for roundness. • Use a combination square to check for squareness of the face in relationship to the sides. • Repeat steps if necessary until desired face is reached. Answers to Questions 1. 2. 1. 9. 2. 8. 3. 7. 6. 4. 5.