Fiber Reinforced Concrete

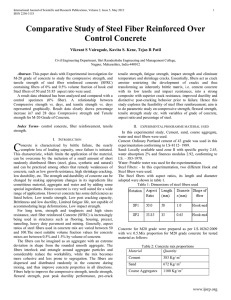

advertisement

FIBER REINFORCED CONCRETE (FRC) Created and presented by: Baquero, Victor Brown, Chris Thielbar, Trenton What is fiber reinforced concrete A concrete consisting of, cement, water, fine and coarse aggregate, along with discontinuous fibers. Types of fibers Types of fibers include Steel Plastic Polyester, Polypropylene, Polyethylene Glass Natural Wood materials cellulose, Bamboo, Elephant grass All are available is different shapes sizes and materials Types of fibers Steel Shapes Steel fibers are adhered together before mixing and separate while mixing to ensure uniform distribution Advantages of using fiber reinforced concrete versus plain concrete Improves toughness of concrete Flexural strength is improved by up to 30% by decreasing the propagation of cracks Improves tensile strength More economical than steel reinforcement Less prone to corrosion Gives an alternative way to reinforce concrete other then traditional steel rebar PCC FRC Corrosion Unlike rebar there is not galvanic cell created in the fibers No anodic/cathodic reaction pH level of concert protects steel fibers from corrosion Applications Applications include: Pipes Tilt-up Panels Shotcrete Slabs Counters tops Bath tubs Tiles Properties Durability Made with a high content of cement and low water to cement ratio When properly compacted and cured, concrete with steel fibers is very durable Workability Affects workability Compensate by adding superplasticizers Properties Compressive behavior of steel FRC Keeps integrity after failure Strength slightly enhanced Tensile behavior increase tensile strength Has little effect on the modulus of elasticity, drying shrinkage, and creep Production Production is guided and controlled mainly by the American Concrete Institute, ASTM, and various building codes Production involves 5 Steps 1. 2. 3. 4. 5. Determine typical Uses and Specifying FRC Materials Mixture Proportioning Batching, Mixing, Delivery and Sampling Placing and Finishing Summary Fiber reinforced concrete is one of the oldest methods for reinforcing concrete The main purpose of fiber reinforcement is to increases its structural integrity and improve flexural behavior There are many different types of fiber that can be used for concrete reinforcement. Is an economical way to reinforced concrete compared to regular steel. References Mamlouk, Michael, and John Zaniewski. Materials for Civil and Construction Engineers. Second Edition. N.J.: Pearson Hall, 2006. 576. Print Mehta, P.K., and P.J.M Monteiro. "Fibers in Concrete." University of Californa, Berkeley, 04,May,2006. Web. 1 Dec 2010. <http://www.ce.berkeley.edu/~paulmont/241/fibers.pdf Nemati, Kamran. "Progress in Conctet Technology: Fiber Reinforced Conctete (FRC)." University of Wahington. University of Washington, Seattle, Wahington, USA. Spring 2010. Lecture. SMiRT 19, . "WOKSHOP ON: Fiber Reinforced Concrete." ASMiRT, 17,August,2007. Web. 1 Dec 2010. <http://www.iasmirt.org/iasmirt-2/SMiRT19/SMiRT19_WH3_Tatnall.pdf>.