Last Planner® an introduction for corporate leaders

advertisement

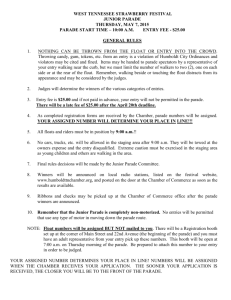

Last Planner® National Capital Region Community of Practice Victor Sanvido – Southland Industries Matt Bruening – Southland Industries 1 Agenda 2 • • • • • • • • • Introductions Parade of Trades and Review Milestone Master Planning Pull Planning Make Ready Planning Weekly Work Plan Reliable Promising Measuring Performance What will you change? Learning Outcomes 3 1. Understand LPS is a system change and an integral part of the overall lean transformation of a project or an enterprise 2. Understand the Last Planner System and its goal of reliable workflow 3. Understand that LPS requires new thinking and new behavior from top managers and participants 4. Be aware of how the LPS can eliminate waste in your process Introductions 4 • Name • Organization • Experience with Lean or Last Planner • Personal goals/outcomes for the training • Existing concerns about Lean or Last Planner 5 Parade of Trades tables of 6 or 7 arrows point to screen 6 • Parade of Trades • • • • • each take your sheet 1 = concreter …… 7 = painter give the dice to the painter give the chips to the concreter • check you have 35 pieces (units of work) • place pieces on your left 7 Parade of Trades 8 • dots on the die represent the number of units of work your team can do that week • each die has an average roll of 3.5 • each trade has to deliver 35 units of work • how many weeks to complete the work • for each trade? • 10 weeks • for the whole project? • 16 weeks Parade of Trades 9 • painter says “start week 1” Parade of Trades & passes die to the left • die travels round group until it meets a trade (concrete) with available work to the left • concrete rolls die • records number rolled on record sheet … 10 • pass die to painter … Parade of Trades number on dice here 11 number of pieces passed to next trade number of pieces on your left • painter says “start week 2” Parade of Trades & passes die to the left • die travels round group until it meets a trade (bricklayer) with available work to the left • bricklayer rolls die • records number rolled on record sheet … 12 Parade of Trades number number number of pieces on dice of pieces number number number on your here passed to of pieces of pieces on dice left next passed to on your here trade next left trade when you have processed all 35 pieces total both these two cols 13 Parade of Trades • • Please complete this form for each trade Then total the two center columns week all pieces complete total of column 1 total of column 3 highest number in col 3 total these two cols circle color of dots on your dice 14 Parade of Trades Results Review 15 Parade of Trades Results 40 35 30 25 20 Worst 15 Best 10 5 0 1 1.1.1.6.6.6 16 2 1.2.2.5.5.6 3 1.2.3.4.5.6 4 2.2.3.4.5.5 5 2.3.3.4.4.5 6 3.3.3.4.4.4 Project Flow 17 Discussion 18 • How do we cope with unpredictable workflow now? • Who manages the coping? • How would more predictable workflow benefit the company? Projects? • What obstacles do you see to making the workflow more predictable? Different Form of Managing Projects 19 Master Master Scheduling SHOULD Milestones Phase “Pull” Planning Specify handoffs Clarify coordination CAN Lookahead Planning Make ready & Launch Re-Planning when needed WILL Weekly Work Planning DID 20 Set milestones Learning Promise Measure PPC & Act on reasons for failure to keep promises Conversations & Commitments 1. prepare 2. negotiate request declare acceptance 4. assess 21 after Fernando Flores conditions of satisfaction & due date quality promise declare complete 3. perform Making Reliable Promises I can do it when … I have the ability to say “no” I am competent to perform - or I have access to competence I estimate how long hands-on it will take commitment processes I have the capacity & I’ll allocate it are conversation acts I am not having a private unspoken conversation in conflict with promise I will be responsible (clean up the mess) 22 Which Of These Are Promises? & which of these are useful? 23 I will do … yes maybe I can do … perhaps I will … yes I will do … if … I could do it no I cannot do it Sure I’ll try to do … Create Reliable Workflow essential to stick to commitments/promises project success make work ready coordinate actions learn & improve rapidly 24 High level view of project overview: Master Planning 1. Confirms feasibility of project 2. Highlights long-lead items 3. Identifies phases 4. Establish common understanding of the deliverables for each phase. 25 Milestone Master Planning 26 • This is about the Pull Planning Process conversation! • Start at the end of the process and work backwards • Reliable hand-offs • Focus on the batch size of a handoff • Understand the Conditions of Satisfaction for Hand-off 27 28 29 Make Ready Planning 30 • What work is coming up in the next 3-4 weeks? • Have all the constraints been removed? • What can we do? Make Ready Planning 31 • Have all the constraints Weekly Work Plan been removed? • What will we do this week? • What is our back-up plan? • Who relies on this work? 32 Group Discussion 33 • What needs to be on the plan to complete a task? • • Task Requirements • • • • • • Supervisor Labor Material Tools/Equipment Information Safe Work Place Prerequisite Work Temporary Facilities (Scaffolding, etc.) • Performance Goals 34 Weekly Work Plan 35 Weekly Work Plan 36 Weekly Work Plan 37 Learning 38 • Measuring percent of plan complete (PPC) • Deep dive into reasons for failure • Developing and implementing lessons learned PPC 39 Reasons for Variance 40 What will you change? list individually then discuss in groups of 3-4 report back 41 • What are the implications of this for the way you lead and manage? • How will you change your behavior to support LPS? Learning Outcomes 42 1. Understand LPS is a system change and an integral part of the overall lean transformation of a project or an enterprise 2. Understand the Last Planner System and its goal of reliable workflow 3. Understand that LPS requires new thinking and new behavior from top managers and participants 4. Be aware of how the LPS can eliminate waste in your process QUESTIONS? 43 Thank You 44